60-Second Summary

OPEX® Perfect Pick® is a field-proven automated storage and retrieval system (AS/RS) that has delivered unmatched reliability and ROI since 2013. Designed around the simple, self-charging iBOT®, Perfect Pick eliminates complexity to maximize uptime, throughput, and space savings. Real-world results from iHerb, Newegg, Knipper, and Ingram Micro showcase faster fulfillment, 90% labor reductions, and scalable performance in even the most demanding environments. Unlike grid-based or shuttle systems, Perfect Pick offers direct tote access and modular expansion. OPEX’s locally based equipment service makes it the reliable choice in a market full of hype.

Proven Performance that Outpaces the Competition

What does 18,000 orders a day, 1/10th the labor, and less than 15 minutes from dock-to-ship have in common?

Perfect Pick.

Since its public debut at ProMat on January 21, 2013, OPEX Perfect Pick has quietly revolutionized warehouse automation. While competitors rush to market with promises of next-generation technology, Perfect Pick has spent over a decade proving its reliability in the most demanding fulfillment environments on earth.

In an industry where the global automated storage and retrieval systems market size is projected to grow from $9.57 billion in 2025 to $14.95 billion by 2032, longevity matters. Every year brings new automation startups, ambitious promises, and unproven technologies. Yet, after more than ten years of continuous operation, Perfect Pick remains the gold standard for reliability in automated storage and retrieval systems.

A Decade of Innovation and Reliability

The story of Perfect Pick begins with a simple observation: existing shuttle technologies were too complex. When OPEX introduced Perfect Pick as a simple design based on a single component, the iBOT, they weren’t just launching another AS/RS. We were reimagining what warehouse automation could be.

OPEX launched Perfect Pick in 2013 as part of our expansion into warehouse automation, building on four decades of automation expertise in document and mail handling. OPEX had been perfecting automated systems since 1973, bringing that institutional knowledge to address warehouse challenges.

The timing was perfect. E-commerce was exploding, labor was becoming scarce, and warehouses needed solutions that worked, not just in demonstrations, but day after day, year after year, in real-world conditions.

Core Capabilities that Stand the Test of Time

The IBOT Advantage: Simplicity Breeds Reliability

At the heart of Perfect Pick’s enduring success is a design philosophy that prioritizes reliability over complexity. The iBOT wireless robots embody this approach:

- No Single Point of Failure: Unlike systems dependent on central lifts or complex grid infrastructure, each iBOT operates independently.

- Self-Charging Design: Continuous operation without battery swaps or charging downtime.

- 80-Pound (36.3kg) Payload: OPEX iBOTs have a higher payload capacity than most competitors (AutoStore: 66 lbs (30kg)., Exotec: 66 lbs. (30kg).

This simplicity translates directly to uptime. When an iBOT needs maintenance, it’s removed from the system without stopping operations. A stark contrast to grid-based systems, where a single robot failure can create cascading delays.

Dense, Smart Storage that Saves Space

Perfect Pick delivers an 8:1 space savings ratio through intelligent vertical storage design.

- Height Advantage: Perfect Pick systems build up to 32.5’ (9.9m) feet high, taller than AutoStore (25.7′ or 7.8m) and Ocado (24.9′ or 7.6m).

- 200-Foot (60.9 m) Aisles: Maximize storage density within existing facilities.

- Larger Tote Volume: 20×30″ (508mm x 762mm) footprint provides more cubic storage than standard EU totes.

- Double-Deep Configuration: Perfect Pick HD offers even greater density without sacrificing accessibility.

- Present Station: Present Stations can be located at one or both ends of the aisle and can be raised on a mezzanine to provide easier access to the system below.

Unlike cube-based systems that require “digging” through stacked bins, every Perfect Pick tote remains individually accessible. This design choice continues to prove its worth as order profiles become more complex and customers demand faster fulfillment.

Cortex® ECS: Intelligence Refined Over Time

The Cortex® Equipment Control System (ECS) represents a decade of continuous refinement based on real-world feedback:

- Dynamic Slotting: Automatically optimizes inventory placement based on SKU velocity

- Universal Integration: API compatibility with virtually any WMS

- Visual Picking Guidance: Intuitive interfaces reduce training time to minutes

- Predictive Analytics: Leverage historical data to optimize future performance

Proven in the Field: Real Customers Wins

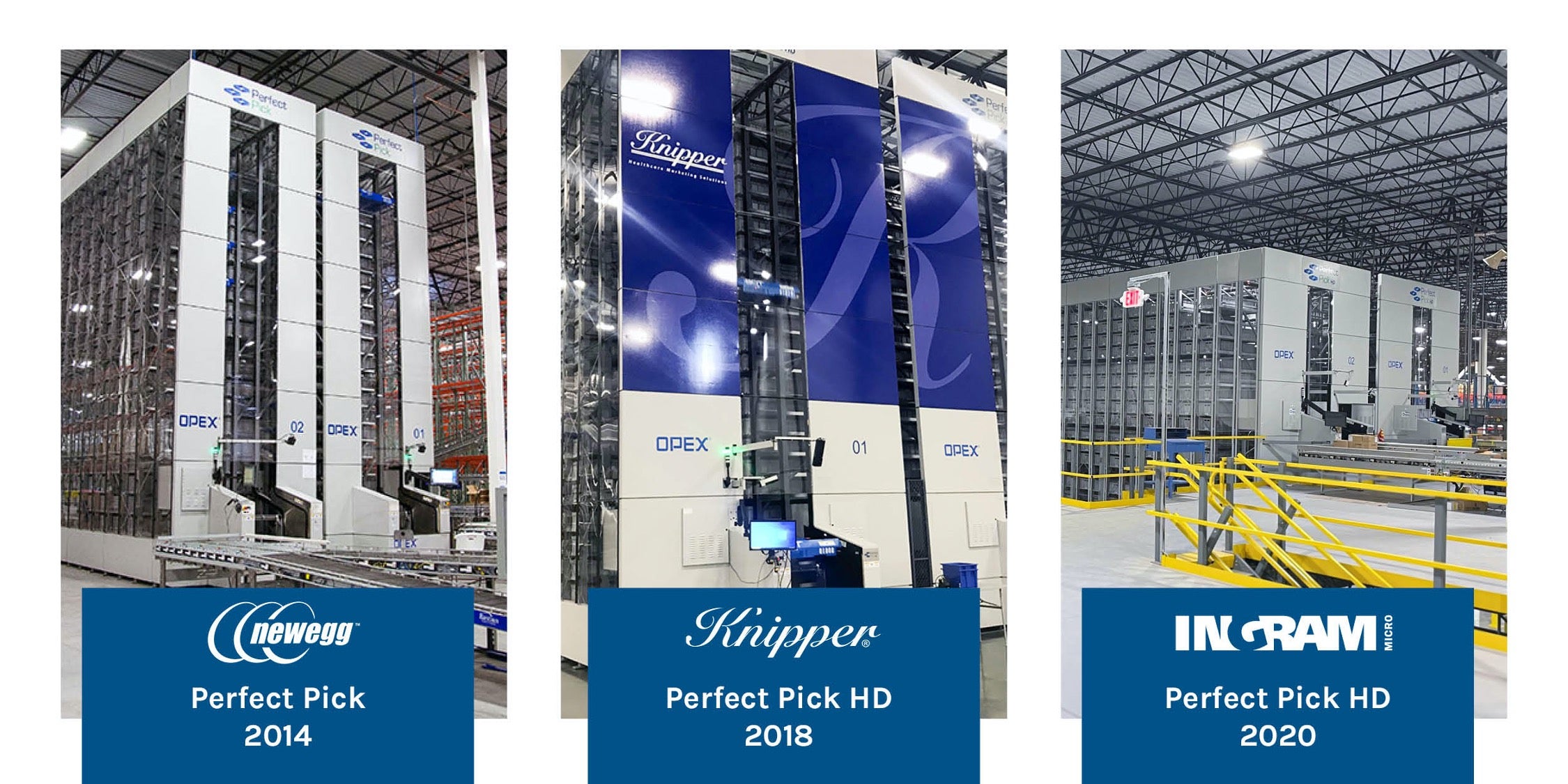

Newegg (Since 2014): Scaling for Peak Performance

Electronics retailer Newegg demonstrates Perfect Pick’s ability to handle extreme volumes:

18K

orders/day during peak operations

17

million products stored securely

20

minute cycle times, maintaining consistency even at peak

The system’s reliability has been crucial for Newegg, where high-value electronics require both speed and accuracy. Perfect Pick delivers both, year after year.

Knipper (Since 2018): Pharmaceutical Precision

In pharmaceutical distribution, there’s no margin for error. Knipper’s results prove Perfect Pick’s precision:

6

seconds between order presentations

3K

orders/day throughput

99.9%

accuracy in regulated environments

Ingram Micro (Since 2020): Managing Complexity at Scale

Technology distribution at Ingram Micro requires handling diverse SKUs efficiently:

3

Distribution Centers

with Perfect Pick HD

7K

SKUs accessible from a single workstation

36

iBOTs in one DC

Expanding the Ecosystem: Perfect Pick HD and TOTE I/O

The Perfect Pick system has undergone multiple enhancements to meet the evolving needs of modern warehousing. To date, it has progressed through three major versions:

- 1.0 Standard (SD) – The original model designed for efficient, reliable picking.

- 2.0 High-Density (HD) – An upgraded version offering greater storage capacity within the same footprint.

- 3.0 CE Certified – The latest version, fully CE certified to meet international safety and compliance standards.

Each iteration reflects a commitment to continuous improvement, scalability, and regulatory compliance.

Perfect Pick HD: Evolution, Not Revolution

Rather than abandoning existing customers with entirely new systems, OPEX evolved Perfect Pick based on operational data:

- Double-deep storage in the Perfect Pick HD system versus single-deep in standard Perfect Pick

- Same proven iBOT technology, enhanced for higher density

TOTE I/O: Automation Without Limits

The addition of Tote I/O capabilities demonstrates OPEX’s commitment to continuous improvement.

- 600 cycles/hour fully automated operation

- Eliminates pick stations for lights-out operation

- Enables deployment in cold storage and clean room environments

- Maintains the same reliability standards as the core system

How Perfect Pick Stands Apart From the Competition

With several key technologies in play in the warehousing market, determining the best one for your warehouse can be challenging. Consider your warehouse size, throughput requirements, budget, and preferred level of automation.

Autostore VS. Perfect Pick

AutoStore uses a grid-based structure with small, autonomous robots to store and retrieve products. The system is operated by autonomous robots that move on top of an aluminum cubic grid. Within this grid, storage bins are stacked on top of each other. The robots continuously pick up, rearrange, and deliver bins directly to connected ports for order picking and replenishment. Unlike cube-based storage, Perfect Pick offers direct access to inventory with higher storage density, achieved through a taller system configuration and larger tote sizes.

Perfect Pick Advantages:

- Direct Access: No digging through 12-14 stacked bins with Perfect Pick.

- Higher Payload: Perfect Pick has an 80 lbs (36.3kg) payload vs AutoStore’s 66 lbs capacity (30kg).

- Taller Systems: Perfect Pick reaches 32.5′ (9.9m) vs AutoStore’s 25.7′ (7.8m) maximum height.

- Larger Totes: Compared to AutoStore’s tall tote 16.75” (425mm), Perfect Pick’s 14” tote is ~39% larger by volume.

- No Grid Congestion: Aisle-based design prevents robot traffic jams and facilitates easy hot-picking since Perfect Pick does not need to plan bot routes in advance.

- Reliable Service: No reliance on a third-party for system maintenance and trouble-shooting as OPEX offers the option to service all our machines.

Exotec VS. Perfect Pick

If you compare Exotec with Perfect Pick or Perfect Pick HD, storage density is a major difference. Exotec’s Next Generation Skypod advertises 50% faster picking and 30% denser storage, but OPEX Perfect Pick provides a higher tote payload with larger storage tote sizes than the European industry-standard totes. Exotec offers a taller system at 46’ (14m), but Perfect Pick HD can reach 32.5’ (9.9m) high and 204.9’ (62.45m) long with no delay in inventory access.

Perfect Pick Advantages:

- Payload: Perfect Pick handles payloads up to 80 lbs (36.3kg) vs Exotec’s 66 lbs (30kg).

- Larger Totes: Compared to Exotec’s largest tote 16.5” (420mm), Perfect Pick’s 14” (355mm) tote is ~37% larger by volume.

- Lead Times: Both options require 12 to 14 months for completion

- Reliable Service: No reliance on a third-party for system maintenance and trouble-shooting as OPEX offers the option to service all of our machines.

ShuttleSystems: Why Simple Beats Complex

Traditional shuttle systems from Swisslog, Kardex, and others rely on complex lift-and-transfer mechanisms. While often more expensive than traditional shuttle systems, OPEX Perfect Pick offers higher throughput and greater tote and SKU capacity, providing a better ROI in the long run.

Perfect Pick Advantages

- Perfect Pick has no central lift bottlenecks and iBOTs operate independently.

- OPEX technicians or designated users can perform individual iBOT maintenance without a complete system shutdown.

- Perfect Pick has a faster deployment with less infrastructure.

- There is a lower total cost of ownership over the system’s lifetime of 20-25 years.

The Numbers Don’t Lie: Competitive Comparison

Based on real-world data, here’s how Perfect Pick stacks up:

| Feature | Perfect Pick | AutoStore | Exotec Skypod | Ocado |

|---|---|---|---|---|

| Max Height | 32.5' (9.9m) | 25.7' (7.8m) | 46' (14m) | 24.9' (7.6m) |

| Payload | 80lbs (36.3kg) | 66lbs (30kg) | 66lbs (30kg) | 67lbs (30.4kg) |

| Tote Sizes (LxW) | 20x30" (508x762mm) | 23x15.75” (600x400mm) | 23x15.75” (600x400mm) | 20x13” (508x330mm) |

| Lead Time* | 12-14 months | 6 months | 9-12 months | 8-10 months |

| Freezer/Chilled Environment | 34°F-90°F (1°C-32°C) | –4°F-104°F (–20°C-40°C) | 32°F-104°F (0°C-40°C) | 14°F-122°F (-10°C-50°C) |

| Manufacturing | USA | Norway | France | Europe |

*Current known lead times as of August 2025

While competitors may win on specific metrics, Perfect Pick delivers where it matters most: proven reliability, superior support, and consistent performance year after year.

Overcoming Objections: The Truth About Perfect Pick

“It’s More Expensive.”

Yes, Perfect Pick requires significant investment. But consider:

- Labor savings of up to 90% pay for the system

- Space savings defer or eliminate facility expansion

- Reliability reduces the hidden costs of downtime

When calculated over the system’s 20-25 year lifespan, Perfect Pick often delivers the lowest cost per pick.

“Lead Times Are Too Long”

At 12-14 months, Perfect Pick’s lead times reflect high demand and careful manufacturing. But consider:

- Rushed deployments often fail

- Perfect Pick’s proven implementation process reduces risk

- The system runs reliably for decades—a few extra months of planning pays dividends

“It Can’t Handle Our Temperature Requirements.”

While Perfect Pick isn’t designed for deep freeze operations, it excels in ambient and cooler environments (34-90°F/1.1-32.0°C). For true cold chain applications, Tote I/O enables automated operation without human exposure. Additionally, refrigerated and freezer totes offer a flexible solution for storing temperature-sensitive items within the system.

“We Need More Flexibility.”

Perfect Pick’s modular design provides more flexibility than critics acknowledge:

- Start with one aisle, expand aisle size and quantity as needed

- Add iBOTs to increase throughput and build in redundancy

- Integrate new capabilities like Tote I/O

- Upgrade to HD versions without replacing infrastructure

The Reliability Difference: Why Longevity Matters

In warehouse automation, the newest technology isn’t always the best technology. Consider:

- Proven Track Record: Perfect Pick has over 10 years of continuous operation across industries while customers have trusted OPEX for over 50 years.

- Institutional Knowledge: OPEX has refined Perfect Pick and Perfect Pick HD based on millions of picks and customer feedback.

- Stable Company: Family-owned since 1975, OPEX is not dependent on venture capital or shareholders.

- Speed: Perfect Pick is one of the top-performing systems in terms of speed (up to 1,000 tote presentations per hour) when configured with Tote I/O and double-ended present stations.

This deep understanding of customer challenges drives OPEX’s commitment to reliability over complexity, ensuring that businesses of all sizes can successfully implement automation without unnecessary risk.

A System That Grows With You

Perfect Pick succeeds because it solves real problems with proven technology. While competitors chase the next big thing, Perfect Pick customers are too busy fulfilling orders to notice.

From Newegg’s 18,000 daily orders to Knipper’s pharmaceutical precision and Ingram Micro’s SKU complexity, Perfect Pick has proven its worth across every metric that matters:

- Reliability: Years of continuous operation

- Scalability: From single aisles to massive operations

- Support: US-based manufacturing and service

- Evolution: Continuous improvement without abandonment

- Results: Measurable ROI in under 3.5 years

In an industry full of promises, Perfect Pick delivers proof. After more than a decade of perfecting warehouse automation, one thing is clear: when reliability matters more than hype, Perfect Pick remains the proven choice.

Other Resources You Might Find Helpful

Dentegra Dental: Claims Processing System No Longer Feels Like a Painful Root Canal

What is Right-Speed Scanning?

The Benefits of Milling Cutting Technology

Gemini™ Right-Speed Scanner

The Imagine Group: Accelerating the Data Entry Process for Returned Mail with a Solution from OPEX® and CPT

Falcon® Scanner Demo

Taking the Right Steps to Digital Mailroom Success

OPEX® Falcon+® RED One-touch Scanning

San Bernadino County Falcon+ Video

The American Samoa DOE Streamlines the Digital Records Management Process

NEXT LEVEL AUTOMATION

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.