Increasing Distribution Center Productivity Using Automated Put Walls

Sure Sort and Sure Sort X Applications

27 min read

60-Second Summary

OPEX® Sure Sort® and Sure Sort® X are high-performance robotic sorting solutions designed to enhance efficiency, reduce labor costs, and improve order accuracy in warehouses and fulfillment centers. Traditional manual sorting methods struggle to keep pace with rising e-commerce demand, leading to delays and inefficiencies. Sure Sort and Sure Sort X process up to 2,400 and 2,100 items per hour respectfully, seamlessly integrating with WMS and WCS systems to optimize throughput and space utilization. Companies around the globe have successfully implemented these systems, achieving faster order fulfillment, reduced labor reliance, and significant cost savings. With a rapid ROI in under two years, these solutions provide a scalable, future-proof approach to warehouse automation.

Chapter 1

The Growing Need for High-Speed, Scalable Sortation

Distribution centers face increasing pressure to optimize efficiency, reduce operational costs, and adapt to shifting supply chain demands. The rise of e-commerce, omnichannel fulfillment, and rapid delivery expectations has created a greater need for high-speed, scalable, and space-efficient sorting solutions. Traditional put walls and manual sortation processes have become bottlenecks, leading to higher labor costs, slower throughput, and inconsistent order accuracy.

To meet these challenges, Sure Sort® and Sure Sort® X, developed by OPEX®, are automated, high-performance robotic sorting solutions designed to improve operational efficiency across various industries, including e-commerce, retail, and third-party logistics (3PL).

Key Benefits of Sure Sort and Sure Sort X:

Automated sortation is no longer a luxury—it is a necessity for warehouses seeking higher efficiency, faster order fulfillment, and lower operational costs. With Sure Sort or Sure Sort X, businesses can streamline their logistics operations, reduce sorting errors, and achieve a rapid return on investment (ROI) in two years or less.

Increased Throughput

Sure Sort processes smaller items up to 2,400 items per hour, while Sure Sort X sorts larger items up to 2,100 items per hour.

Scalability & Modularity

Expansion modules, additional iBOT® robots, and flexible bin configurations allow businesses to grow their sorting capacity without major infrastructure changes.

Reduced Labor Dependency

Businesses can minimize manual handling by automating sortation, reducing labor costs, and improving accuracy.

Optimized Space Utilization

The compact footprint of Sure Sort and Sure Sort X enables facilities to maximize productivity within limited space.

Seamless System Integration

Both solutions integrate easily with existing Warehouse Management Systems (WMS) and Warehouse Control Systems (WCS) for real-time sorting operations.

Chapter 2

The Sorting Challenge for Businesses

The High Cost of Traditional Sortation

Sorting remains one of the most labor-intensive and expensive processes in warehouse operations. Traditional put walls and manual sorting methods require significant human intervention, resulting in:

High Labor Costs

Increasing wages and a tightening labor market make manual sortation less sustainable.

Lower Throughput

Manually sorting hundreds or thousands of orders per hour limits efficiency and order processing speed.

Error-Prone Operations

Human handling increases the risk of mis-sorts and order inaccuracies, impacting customer satisfaction.

Scalability Constraints

Expanding a manual sortation process typically requires additional space and labor, making growth costly and inefficient.

Considering these challenges, the need for high-speed, space-saving, and reliable automated solutions has never been greater.

Why Automation is the Answer

Automation enhances sorting accuracy, speed, and efficiency while reducing dependency on manual labor. Sure Sort and Sure Sort X address key operational challenges by:

- Reducing labor-intensive processes and improving overall efficiency.

- Eliminating bottlenecks caused by manual sortation and traditional put walls.

- Improving accuracy with six-sided barcode/RFID scanning and automated pack-to-light sorting.

- Maximizing space efficiency with a dense sorting array, reducing overall warehouse footprint.

- Offering seamless scalability, allowing businesses to expand their sortation capacity with minimal disruption.

The Future of Warehouse Sortation

Modern distribution centers, e-commerce hubs, and retail fulfillment centers require solutions that reduce operational complexity, lower costs, and improve sorting performance.

- Automation is no longer optional—it is a competitive necessity.

- Scalability ensures future growth without excessive capital expenditure.

- Optimized warehouse space utilization leads to greater efficiency.

- Higher throughput rates mean faster, more accurate fulfillment.

Sure Sort and Sure Sort X provide a future-proof solution for organizations looking to automate and scale their sorting operations without sacrificing accuracy or speed.

Chapter 3

What ARE Sure Sort and Sure Sort X?

Automated sortation transforms warehouse operations, and Sure Sort and Sure Sort X are at the forefront of this shift. These solutions offer a high-speed, scalable, and space-efficient approach to handling order fulfillment, parcel sorting, returns processing, and more.

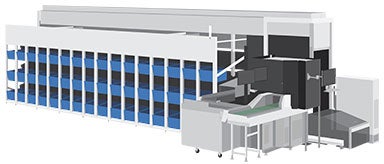

Both systems utilize iBOT robotic sorters to automate item movement, sorting, and delivery, reducing reliance on manual labor while increasing accuracy and throughput. Each system is tailored to different operational needs, making it essential to understand their unique capabilities.

How Sure Sort and Sure Sort X Work

At their core, both Sure Sort and Sure Sort X operate on a fully automated, high-precision sorting mechanism that follows these key steps:

- Item Induction: Products are placed onto the system via a conveyor or operator station. The system scans barcodes or RFID tags to determine the destination of each item.

- Automated Routing: Using integrated software and warehouse control systems (WCS), items are dynamically assigned to designated sort locations based on configurable criteria.

- iBOT Transport & Sorting: Autonomous iBOTs, powered by self-charging ultra-capacitors, retrieve and transport items to the correct bin, tote, chute, or order container.

- Final Destination & Order Processing: Once sorted, items are ready for final processing, whether packaging, shipping, or further warehouse handling.

Key Features of Sure Sort and Sure Sort X

Both solutions offer a range of advanced features designed to maximize warehouse efficiency:

- iBOT Robotic Sorters: High-speed, autonomous robotic vehicles navigate within the system to transport items with precision. iBOTs can be quickly and easily removed from the system for preventive maintenance or repair, resulting in minimal downtime.

- High-Throughput Processing: Sure Sort sorts up to 2,400 items per hour, while Sure Sort X handles up to 2,100 items per hour, requiring minimal operators.

- Six-Sided Barcode & RFID Scanning: Each item’s barcode or RFID tag can be scanned from multiple angles to ensure accurate identification and placement.

- Pack-to-Light (PTL) System: LED indicators guide warehouse staff for quick and efficient order consolidation or additional handling instructions.

- Scalability & Modularity: Expandable design allows businesses to increase sorting capacity with additional modules, iBOTs, and bin configurations.

- WMS & WCS Integration: Seamless connectivity with WMS and ECS ensures real-time order processing and tracking.

- Energy Efficiency: Both systems operate on ≤2.5 kW of single-phase power, significantly reducing energy costs. iBOTs utilize ultra-capacitor batteries that recharge automatically as they move through the system, eliminating the need to remove them for charging.

Comparing Sure Sort and Sure Sort X

While both solutions offer high-speed automation, they cater to different warehouse needs.

| Feature | Sure Sort | Sure Sort X |

|---|---|---|

| Throughput | Up to 2,400 items per hour | Up to 2,100 items per hour |

| Max Item Weight | 5 lbs. (2.26 kg) | 20 lbs. (9 kg) |

| Max Item Size | 15" x 12" x 6" (38.1 cm x 30.5 cm x 15.25 cm) | 18" x 14" x 8" (45.7 cm x 3.5 cm x 20.3 cm) |

| Scalability | Expandable up to 11 modules | Expandable up to 16 modules |

| Best For | Small-item fulfillment, retail, micro-fulfillment | Large-item fulfillment, parcel sorting, high-capacity DCs |

| WMS Integration | Yes | Yes |

| Pack-To-Light System | Yes | Yes |

| Power Consumption | ≤ 2.5 kW | < 2.5 kW |

| No. of Operators | ≤ 3 | ≤ 3 |

The Competitive Advantage of Sure Sort and Sure Sort X

Sure Sort and Sure Sort X offer a significant competitive edge over traditional put walls and conveyor-based sorting systems by improving efficiency, reducing costs, and optimizing warehouse space. Their compact footprint allows warehouses to maximize productivity without requiring large-scale infrastructure expansions, making them an ideal solution for facilities looking to scale efficiently. Unlike manual sortation methods, which are labor-intensive and prone to human error, these automated systems minimize handling, leading to greater order accuracy and faster fulfillment times.

In addition to improving operational efficiency, these systems contribute to cost savings by lowering labor dependency and reducing energy consumption. With ≤2.5 kW of single-phase power, Sure Sort and Sure Sort X operate with minimal energy requirements, making them an environmentally conscious and cost-effective alternative to larger, power-hungry sortation systems. Their ability to seamlessly integrate with a WMS and WCS ensures real-time data tracking and enhanced visibility into inventory movement, allowing businesses to make informed decisions and optimize workflows.

Through their modular and scalable design, Sure Sort and Sure Sort X can easily adapt to increasing order volumes, enabling warehouses to handle peak demand without operational disruptions. Whether sorting small retail items, heavier parcels, or returns, these systems provide the flexibility and efficiency required to meet the ever-changing needs of e-commerce, retail distribution, and logistics. Businesses can achieve higher throughput, reduced costs, and a rapid ROI by adopting Sure Sort or Sure Sort X, solidifying their position in an increasingly competitive supply chain landscape.

Chapter 4

Industry Applications and Use Cases

Automation is transforming warehousing and logistics, and Sure Sort and Sure Sort X are driving innovation across multiple industries. From e-commerce fulfillment to parcel sorting and cross-docking, these systems provide unmatched flexibility for businesses looking to scale operations efficiently.

E-Commerce and

Retail Fulfillment

E-Commerce and Retail Fulfillment

As online shopping demand surges, warehouses must process higher order volumes with tighter delivery windows. Sure Sort and Sure Sort X optimize e-commerce fulfillment by:

- Increasing order throughput, reducing processing bottlenecks.

- Automating order consolidation, improving accuracy, and reducing mis-sorts.

- Reducing labor costs, requiring fewer operators for higher output.

- Handling a wide variety of SKUs, from apparel to electronics and household goods.

Example: A retailer needs to scale operations while reducing reliance on temporary labor during peak seasons. By implementing an automated sorting system such as Sure Sort or Sure Sort X, the company can transition from individual order picking to a batch-picking process, enabling warehouse staff to pick and sort more orders in less time. This minimizes unnecessary walking within the facility, improves efficiency, and reduces seasonal labor needs.

Parcel Sorting and Presort Operations

Parcel Sorting and Presort Operations

For 3PLs and distribution hubs, the ability to sort parcels quickly and accurately is essential. Sure Sort X excels in parcel sorting applications, particularly for:

- Presorting shipments by zip code to reduce carrier fees.

- Sorting packages of varying sizes and weights, up to 20 lbs.

- Optimizing last-mile delivery operations, ensuring faster processing and dispatch.

Example: A leading 3PL is struggling to keep up with rapid growth in e-commerce orders while maintaining its same-day shipping guarantee. Batch-picking and order consolidation require multiple steps and up to eight employees per shift. Implementing Sure Sort streamlines order processing while requiring only three operators, even during peak demand. The system allows the company to handle 4x peak volume without additional labor, ensuring faster parcel sorting and cost-efficient shipping.

Returns Processing and Reverse Logistics

Returns Processing and Reverse Logistics

Returns processing remains one of the most complex and labor-intensive areas in warehouse operations. Sure Sort and Sure Sort X improve efficiency by:

- Automating return categorization based on disposition (reshelving, refurbishing, disposal).

- Sorting returned products faster, reducing backlog.

- Reducing processing costs and minimizing manual handling.

Example: A leader in omni-channel logistics needs to enhance order accuracy and efficiency in handling high-volume returns. Many returned items have barcodes hidden within packaging and require extensive manual handling. Integrating Sure Sort with an RFID scan tunnel increases read rate accuracy to 99%, eliminating manual scanning delays and doubling sortation efficiency This allowed them to process returned items faster, improving inventory turnover and reducing labor strain during peak return periods.

Cross-docking and Sort-to-Aisle Fulfillment

Cross-docking and Sort-to-Aisle Fulfillment

For retailers and distributors, cross-docking enables faster material flow and inventory movement without long-term storage. Sure Sort and Sure Sort X support direct-to-store replenishment and sort-to-aisle applications by:

- Sorting incoming shipments directly to outbound destinations without delay.

- Minimizing handling and storage time, improving inventory turnover.

- Optimizing retail store replenishment, ensuring product availability.

Example: A global apparel manufacturer relies on manual put walls for order fulfillment, which slows down processing and creates inefficiencies for in-store replenishment. Deploying Sure Sort allows the company to streamline sorting and direct-to-store shipments while reducing reliance on manual labor and expediting the transfer of inventory to retail locations. The system’s faster order processing enables more consistent in-store stock availability, helping them maintain a competitive edge in a fast-moving environment.

Kitting and Subscription Box Fulfillment

Kitting and Subscription Box Fulfillment

For companies assembling product kits, subscription boxes, or bundled orders, Sure Sort and Sure Sort X offer:

- Automated product matching and sorting, reducing errors.

- Streamlined kitting workflows, speeding up order fulfillment.

- Scalability to accommodate varying kit configurations.

Example: A large wholesaler manually assembles supply kits with up to 44 items per pack, leading to slow fulfillment times and excessive labor costs. Implementing Sure Sort X can reduce manual labor by 65% while increasing daily order pack output. The system allows for batch processing of kits and improves order accuracy while enabling them to handle seasonal spikes in demand without additional staff.

Chapter 5

Comparative Advantages of Sure Sort and Sure Sort X

In an industry where speed, accuracy, and efficiency define success, automated sortation systems must deliver tangible advantages over traditional methods. Sure Sort and Sure Sort X are designed to provide higher throughput, greater flexibility, and lower operational costs, making them ideal solutions for warehouses, fulfillment centers, and distribution hubs. While both systems leverage advanced iBOT technology for high-speed, precision sorting, each is optimized for different operational needs.

Efficiency and Throughput

Sorting speed is critical in meeting increasing order volumes, especially in e-commerce and high-volume distribution environments. Sure Sort offers a throughput of up to 2,400 smaller items per hour, while Sure Sort X is designed to handle up to 2,100 larger items per hour, making both systems significantly faster than manual sortation or traditional put walls.

Both systems ensure continuous operation by utilizing iBOTs, which self-charge as they move throughout the system, minimizing downtime by removing the need for manual charging. Unlike labor-intensive processes that slow down due to fatigue or shift changes, automation maintains a consistent, high-speed sorting rate, ensuring on-time order fulfillment and improved warehouse efficiency.

Scalability and Space Utilization

Warehouses often struggle with space constraints as order volumes increase. Unlike conveyor-based sorting systems that require substantial floor space, Sure Sort and Sure Sort X are designed to operate within a dense, compact footprint, allowing facilities to maximize productivity without expanding warehouse infrastructure.

These systems offer modular scalability, meaning businesses can expand sortation capacity by adding additional iBOTs and expansion modules as demand grows. Sure Sort supports up to 11 expansion modules, and Sure Sort X scales up to 16 modules, allowing operations to be easily adjusted without requiring major infrastructure investments.

Handling a Wide Range of Items

Different industries require sortation solutions capable of handling varied product sizes, weights, and packaging types. Sure Sort excels in sorting small to medium-sized items up to 5 lbs., making it ideal for retail fulfillment, pharmaceuticals, and lightweight e-commerce shipments. In contrast, Sure Sort X is engineered to handle larger and heavier items and parcels up to 20 lbs., making it well-suited for parcel sortation, 3PL operations, and bulk fulfillment applications.

Both systems feature advanced barcode and optional RFID scanning technology, ensuring accurate sortation of non-traditional packaging, such as clear plastic bags, cylindrical objects, and blister packs. This flexibility makes them valuable across multiple industries with diverse inventory profiles.

Seamless Integration with Warehouse Systems

Efficient warehouse automation depends on integrating seamlessly with WMS and WCS software. Sure Sort and Sure Sort X are designed for plug-and-play integration, allowing businesses to quickly connect them with existing software for real-time tracking, inventory management, and order processing.

Integrating Sure Sort and Sure Sort X with WMS/WCS platforms allows businesses to:

Automate sorting workflows, reducing manual intervention.

Improve inventory accuracy, minimizing mis-sorts and processing delays.

Enhance data visibility, allowing for real-time performance monitoring.

Optimize workforce allocation, redirecting labor to higher-value tasks.

This level of connectivity ensures that order fulfillment remains fast, accurate, and scalable, even as demand fluctuates.

Chapter 6

Competitive Landscape

As the demand for high-speed, automated sorting solutions continues to rise, businesses must evaluate how different systems compare efficiency, cost-effectiveness, and scalability. The warehouse automation industry is evolving rapidly, with various solutions ranging from traditional conveyor-based sorters to robotic sortation and AMR (Autonomous Mobile Robot) systems.

Sure Sort and Sure Sort X stand out in this landscape by offering a compact, scalable, and highly efficient sortation solution for modern warehouse operations. Their advantages become clear when comparing them to alternative technologies.

Automation vs. Manual and Put Wall Systems

Traditional manual sorting and put wall systems rely heavily on labor, requiring multiple operators to scan, place, and consolidate orders. This method introduces high labor costs, slower processing times, and increased human error rates.

- Sure Sort and Sure Sort X automate these processes, reducing labor dependency while increasing throughput.

- Unlike put walls, which are limited by the number of staff handling orders, Sure Sort and Sure Sort X can scale effortlessly with minimal operators, additional iBOTs, and expansion modules.

- Higher accuracy ensures fewer mis-sorts, reducing costly errors and reprocessing.

While manual sorting may work for low-volume operations, it is not sustainable for businesses experiencing growth or peak-season demand.

Fixed Conveyor-Based Sortation vs. Robotic Sortation

Many traditional conveyor-based sorting systems require extensive warehouse space, fixed infrastructure, and high capital investment. These systems typically involve:

- Complex installation processes requiring weeks or months of downtime.

- Limited flexibility, making it difficult to adapt to changing business needs.

- High maintenance costs due to reliance on mechanical belts, rollers, and diverters.

Sure Sort and Sure Sort X offer a modular, compact alternative, reducing infrastructure costs and providing:

- Faster deployment: Installations can be completed in as little as three days.

- Flexible scalability: Additional modules and iBOTs can be added as demand increases.

- Lower maintenance costs: Fewer moving parts mean reduced wear and tear compared to conveyor systems.

For businesses looking for rapid scalability and cost-effective automation, Sure Sort and Sure Sort X provide a more agile and adaptable solution.

Scalability and Adaptability in Modern Warehousing

Warehouse operations need to adapt to market shifts and volume fluctuations quickly. Many traditional sorting systems lack scalability, requiring new infrastructure investments to accommodate business growth.

Sure Sort and Sure Sort X offer a future-proof solution, enabling businesses to:

- Scale incrementally by adding iBOTs and expansion modules as needed.

- Adapt to multi-channel fulfillment, handling e-commerce, retail, and parcel sorting in the same system.

- Improve flexibility, processing a wide range of product sizes, weights, and packaging types.

These robotic automated systems provide a competitive advantage for companies seeking higher efficiency, cost reduction, and long-term adaptability in an ever-evolving supply chain environment.

The warehouse automation market is rapidly shifting toward more intelligent, scalable, high-speed robotic solutions. Sure Sort and Sure Sort X lead the way by combining throughput efficiency, modular scalability, and seamless WMS/WCS integration to create a high-performance sorting system. In an increasingly competitive landscape, investing in the right automation technology is essential for warehouses looking to stay ahead of demand, reduce costs, and maximize efficiency.

Chapter 7

Success Metrics and ROI

Warehouse automation investments must deliver measurable improvements in efficiency, cost reduction, and throughput. Sure Sort and Sure Sort X provide significant operational and financial advantages, helping businesses optimize sorting workflows, reduce errors, and maximize ROI. This chapter outlines key performance indicators (KPIs) used to evaluate warehouse automation success, along with case studies demonstrating real-world benefits from companies that have implemented Sure Sort technology.

Warehouse Automation KPIs

Order Throughput and Processing Speed

Efficient sorting directly impacts order fulfillment speed, enabling businesses to meet tight shipping deadlines. Sure Sort processes up to 2,400 items per hour, while Sure Sort X handles up to 2,100 items per hour, ensuring high throughput with minimal labor.

- Case Study: Boux Avenue (Apparel Retail and E-commerce)

Boux Avenue, a lingerie and swimwear retailer, implemented Sure Sort to improve batch-picking efficiency. The company successfully transitioned from manual picking to automated sorting, allowing operators to handle 5x more orders per hour while reducing walking distances by 2 km per work assignment. - Case Study: Delta Israel (Apparel E-commerce)

Before automating, Delta Israel required 12 employees per shift to manually sort and fulfill online orders. With Sure Sort, they reduced labor by 50% while achieving a throughput of 1,500 items per hour, ensuring faster and more accurate e-commerce fulfillment.

Accuracy and Error Reduction

Sorting errors lead to costly reships, customer complaints, and operational inefficiencies. Traditional sorting methods often have an error rate of 0.5% to 2%, while Sure Sort and Sure Sort X reduce errors to below 0.1% through automated barcode and RFID scanning.

- Case Study: Bleckmann (3PL)

Bleckmann, a leading 3PL provider, faced challenges scanning barcodes hidden inside poly-bagged apparel items. Implementing Sure Sort with an RFID scan tunnel increased read rates to 99%, doubling sorting efficiency while reducing errors. - Case Study: Rocky Mountain ATV (Automotive OEM Parts Distribution)

Rocky Mountain ATV’s Kentucky distribution center needed 20–25 employees for manual order sorting. Integrating Sure Sort improved order accuracy to 99.97%, reducing mis-ships and customer service issues.

Labor Cost Savings and Workforce Optimization

Labor shortages and rising wages have increased the cost of warehouse operations. Sure Sort and Sure Sort X minimize labor requirements, enabling businesses to reduce workforce dependency while improving productivity.

- Case Study: Kookaburra Educational Resources (Kitting & Fulfillment)

Kookaburra’s manual kitting process required 60 employees to sort and pack student supply kits. Sure Sort reduced labor by 65%, eliminating the need for a night shift while increasing sorting rates to 2,400 items per hour. - Case Study: NPFulfilment (E-commerce and 3PL)

NPFulfilment, an Australian 3PL, relied on eight employees for manual order consolidation. After implementing Sure Sort, only three employees were needed, reducing labor by over 60% while handling 4x peak-season volume without hiring additional staff.

Space Utilization and Scalability

Warehouse space is a premium resource, and businesses need compact, high-density solutions to optimize sortation capacity. Sure Sort and Sure Sort X operate within a small footprint, unlike conveyor-based systems that require large infrastructure investments.

- Case Study: NPFulfilment (E-commerce and 3PL)

Due to its frequent warehouse relocations, NPFulfilment needed a modular, movable automation solution. Sure Sort’s compact footprint allowed relocation within the warehouse, optimizing space usage without requiring facility expansion. - Case Study: Boux Avenue (Apparel Retail and E-commerce)

Boux Avenue’s distribution center transitioned from manual order picking to Sure Sort without increasing warehouse space. The system efficiently handled 95% of their SKUs, excluding oversized items, allowing for seamless scalability during peak seasons.

Energy Efficiency and Cost Savings

Automation must balance performance with sustainability. Sure Sort and Sure Sort X operate on ≤2.5 kW of single-phase power, significantly reducing energy consumption compared to conveyor-based sorting solutions.

- Case Study: Bleckmann (3PL)

Bleckmann’s adoption of Sure Sort not only increased efficiency but also reduced overall operational costs, aligning with the company’s sustainability initiatives while supporting peak-season demand.

Achieving a Strong Return on Investment (ROI)

Warehouse automation requires a clear ROI to justify capital expenditure. Sure Sort and Sure Sort X provide a fast payback period, with most businesses recovering their investment in two years or less.

- Case Study: Rocky Mountain ATV (Automotive OEM Parts Distribution)

Rocky Mountain ATV reduced manual labor by 45%, increasing order fulfillment speed. Their investment in Sure Sort resulted in a rapid ROI, driven by lower operating costs and increased customer satisfaction. - Case Study: Delta Israel (Apparel E-commerce)

Delta Israel cut labor costs in half while significantly improving order processing speed and accuracy, achieving full ROI within 24 months. - Case Study: Boux Avenue (Apparel Retail and E-commerce)

Reducing seasonal labor requirements by 33% allowed Boux Avenue to save hundreds of thousands in labor costs while maintaining high order throughput, demonstrating fast ROI and long-term cost savings.

The Business Case for Sure Sort and Sure Sort X

Sure Sort and Sure Sort X enable businesses to increase efficiency, reduce costs, and improve fulfillment accuracy, leading to faster order processing, reduced labor expenses, and enhanced warehouse productivity.

Key Takeaways:

Higher throughput: Processing up to 2,400 items per hour, improving order cycle times.

Error reduction: Barcode and RFID scanning ensures +99% accuracy, minimizing mis-ships.

Labor efficiency: Reduces workforce dependency by 50% or more, lowering operational costs.

Scalability: Modular design allows for seamless growth without major facility expansion.

Faster ROI: Most businesses recover their investment in under two years.

Implementing Sure Sort and Sure Sort X allows companies to future-proof their warehouse operations, positioning themselves for long-term success in an evolving supply chain environment.

Chapter 8

Conclusion

Warehouse automation is redefining modern distribution, and Sure Sort and Sure Sort X are at the forefront of this transformation. Designed to maximize throughput, improve accuracy, and optimize labor efficiency, these systems provide a scalable, cost-effective, and high-performance solution for businesses seeking to future-proof their operations.

With an increasing need for faster fulfillment speeds, better space utilization, and lower operational costs, businesses must invest in automation solutions that drive efficiency and long-term savings. Sure Sort and Sure Sort X provide:

- Higher throughput and processing speed for faster order fulfillment.

- Seamless integration with WMS and WCS for enhanced visibility and tracking.

- Scalability to accommodate peak demand without requiring major infrastructure changes.

- Lower labor dependency and operational costs, ensuring sustainable long-term growth.

As the warehouse automation landscape continues to evolve, businesses that embrace automated sortation technology will position themselves as industry leaders, capable of handling future market demands and increasing fulfillment complexity. By implementing Sure Sort or Sure Sort X, companies can reduce costs, improve efficiency, and enhance customer satisfaction, ensuring a competitive edge in an increasingly fast-paced logistics environment.

Are you ready to take your warehouse operations to the next level? Contact OPEX today and speak with a specialist that can assist in navigating the evolving landscape of data-driven decision-making.

Other Resources You Might Find Helpful

NEXT LEVEL AUTOMATION

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.