60-Second Summary

Modern warehouses face continual challenges: rising order volumes, labor shortages, space constraints, and ever-tightening delivery windows. OPEX® Perfect Pick® and Perfect Pick HD (High-Density) offer a proven solution to meet these demands. Combining autonomous iBOT® robotic technology, high-density storage, and intelligent software integration, Perfect Pick helps distribution centers increase throughput, reduce labor dependency, and improve accuracy. With an average ROI under 3.5 years and a considerable number of installations across industries worldwide, Perfect Pick delivers scalable automation that supports today’s fulfillment pressures and tomorrow’s growth.

Chapter 1

The Growing Need for High-Speed, Scalable Automation

The acceleration of e-commerce and omnichannel retail has permanently transformed warehouse operations. Customers expect same-day or next-day delivery, even as order volumes and SKU complexity increase. Meanwhile, labor shortages and rising wages have made it harder to staff operations at scale.

Fulfillment centers need automation systems that improve throughput and accuracy while scaling incrementally with business growth. Perfect Pick addresses this need by delivering high-speed item picking, labor efficiency, and modular scalability without requiring massive facility overhauls.

Key benefits include:

- Faster order processing to meet aggressive turnaround times

- Reduced labor dependency through automated retrieval

- Space savings with high-density vertical storage

- Flexible, modular growth aligned with business needs

Did You Know…

The average Perfect Pick® iBOT® travels up to 1,836 miles in a year?

Chapter 2

The Fulfillment Challenge for Modern Warehouses

Manual picking remains one of the most labor-intensive and inefficient fulfillment processes. It can account for 30-50% of the total labor costs. Workers spend a significant amount of time walking aisles to retrieve items, leading to slow throughput and increased fatigue. Facilities often under-utilize vertical space, forcing costly expansion or off-site storage. Seasonal spikes create additional strain, requiring temporary labor that can be expensive and difficult to source. Errors, bottlenecks, and limited scalability compound these challenges.

Automation offers a path forward. By eliminating manual travel and automating retrieval, Perfect Pick enables fulfillment centers to:

- Handle more orders per hour without increasing headcount

- Maximize vertical space within existing footprints

- Reduce errors with guided picking technology

- Scale incrementally to meet changing demand

Perfect Pick represents the future of Automated Storage and Retrieval Systems (AS/RS) — a flexible, high-speed solution that adapts to the evolving demands of modern warehousing.

Chapter 3

What Is Perfect Pick?

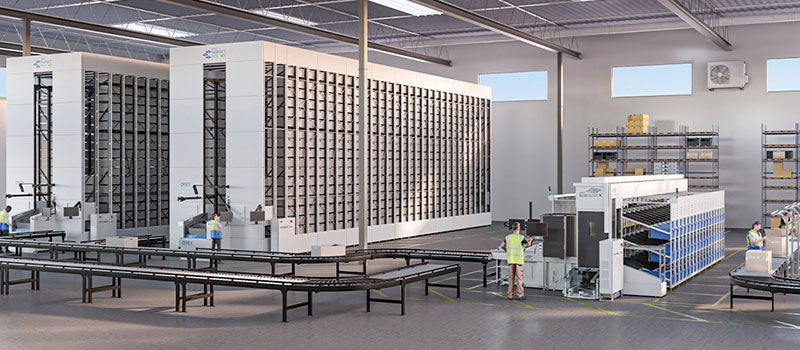

Perfect Pick was the first AS/RS of its time to transform fulfillment by automating the retrieval and delivery of goods directly to the operator, eliminating unnecessary travel and manual searching. This proven technology was introduced to the market in 2013 and is now installed in DCs around the world while remaining the fastest aisle-based AS/RS. It organizes inventory into totes and trays within vertical racks, enabling a high-density storage approach that allows facilities to manage more SKUs without expanding floor space.

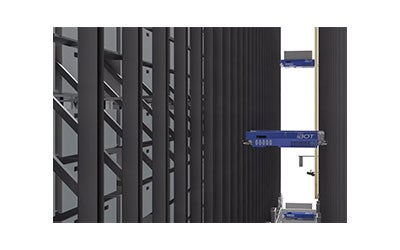

At its core, Perfect Pick operates with autonomous iBOT® robots, which self-charge and navigate aisles horizontally and vertically to access any storage location. These iBOTs retrieve specific totes or trays and deliver them to ergonomic present stations, enabling a true goods-to-person workflow. Operators pick items directly from the tote at an optimal height and position, supported by guided picking technologies such as pick-to-light indicators and order fulfillment software that enhance speed and accuracy.

Key System Components:

iBOT®: Self-charging, trackless vehicles capable of independent movement across storage aisles. iBOTs can carry up to 80 lbs. of inventory.

Totes and Trays: Totes securely store items in the Perfect Pick system. They are available in different sizes to adapt to inventory. Each tote can be subdivided to hold cartons and boxes for flexible storage. Flat trays allow for custom containers (on top of the tray), moved by iBOTs (within a reasonable height).

High-Density Racking: Each Perfect Pick aisle contains racking that holds single or double-deep totes (Perfect Pick HD), allowing iBOTs to travel through the system and retrieve inventory. Build as high as 32.5’ (9.9 m) and 204.9’ (62.45 m) long to maximize the unused vertical space in your warehouse and reduce your footprint.

Cortex® ECS Software: The brains of the operation, the Cortex Equipment Control System (ECS), guides item picking and replenishment to the system while tracking inventory levels. Perfect Pick’s API will also integrate with virtually any WCS system.

Present Stations: iBOTs deliver inventory directly to the operator. Each Perfect Pick aisle can have up to two stations, one at each end.

Workstation (optional): The automated workstation keeps cartons moving toward the system on a conveyor for streamlined picking and replenishment with the push of a button.

After picking, items are packed and dispatched, completing a streamlined fulfillment process. Perfect Pick allows distribution centers to maintain fast processing times even during peak seasons, while reducing dependency on labor and improving space utilization. This integrated approach boosts throughput, lowers operational costs, and enhances customer satisfaction without expanding physical infrastructure.

Chapter 4

Industry Applications and Use Cases

Perfect Pick’s flexible architecture makes it ideal for a wide range of industries and fulfillment environments:

Auto Parts Distribution:

The auto parts industry manages a wide range of SKUs, from small parts to large items. Traditional fulfillment relies on manual, labor-intensive processes. Perfect Pick maximizes vertical space with high-density storage, using trays or divided totes to organize diverse inventory efficiently.

- Manages a wide variety of SKU sizes and packaging requirements.

- Integrates automated picking with bulk storage and manual handling workflows.

- Improves accuracy and safety in high-mix, high-volume operations.

Example: A regional auto parts distributor must streamline fulfillment for over 15,000 SKUs, ranging from small spark plugs to large alternators. By integrating Perfect Pick with its WMS, it can automate the picking of small and medium parts, reducing labor dependence by 30%, cutting picking time by 70%, and increasing storage density by 8:1. The system enables same-day delivery for high-priority orders and improves order accuracy to over 99%, achieving ROI in under two years.

Buffer Systems:

A buffer system temporarily stores items between supply chain stages. Traditional manual processes create inefficiencies and higher labor costs. Perfect Pick transforms buffer systems by maximizing storage density and streamlining retrieval.

- Provides dynamic storage between receiving and downstream operations.

- Smooths fluctuations in order processing by decoupling supply and demand flows.

- Enables real-time responsiveness for high-throughput environments.

Example: A high-volume apparel retailer implements Perfect Pick as an automated buffer system between receiving and packing stations to address staging bottlenecks. Previously reliant on manual staging, the operation faced delays and space constraints during sales events. The company automates tote storage and retrieval with Perfect Pick, allowing items to flow directly to sorting and packing without manual intervention. This can reduce staging labor by 40%, free valuable floor space, and improve throughput during peak seasons.

Distribution Centers:

Distribution centers handle thousands of SKUs while facing growing labor challenges, especially during seasonal peaks. Perfect Pick delivers high-density storage with robotic picking to boost efficiency and accuracy. By integrating Perfect Pick, companies can overcome manual workflow challenges, maximize space, cut labor costs, and confidently scale operations.

- Scales throughput to meet peak season demand without additional labor.

- Reduces reliance on seasonal or temporary workers.

- Supports diverse product profiles and rapid order fulfillment.

Example: A global health and beauty distributor faces seasonal spikes that overwhelm its manual picking operation. Long pick paths and high error rates slow fulfillment, leading to missed shipping windows. By deploying Perfect Pick, the distributor can automate the retrieval of high-velocity SKUs and reduce walking time by 80%. The system helps to increase order throughput by 35%, improve pick accuracy to 99.8%, and eliminate the need for temporary seasonal staff, while handling more SKUs within the same footprint.

Manufacturing Support:

Manufacturers depend on efficient warehouses to manage inventory, fulfill orders, and meet delivery deadlines. Perfect Pick streamlines operations by eliminating unnecessary travel, dramatically increasing picking speed and accuracy.

- Delivers components just in time to assembly or production lines.

- Minimizes manual handling and material movement steps.

- Supports mixed-model production environments with flexible inventory access.

Example: An automotive parts manufacturer needs to improve material flow to its assembly lines, where delays from manual picking slowed production. It implements Perfect Pick to automate the storage and retrieval of components feeding the production floor. iBOT robots deliver parts directly to line-side stations, reducing manual movement steps by 60% and improving order accuracy. The system enables just-in-time (JIT) delivery, eliminates buffer stock staging areas, and supports scalability as product lines expand.

Across industries, Perfect Pick enables faster, more accurate fulfillment while reducing labor requirements and improving operational flexibility.

Chapter 5

Comparative Advantages of Perfect Pick

Perfect Pick stands out by offering:

Modular Scalability: Perfect Pick allows businesses to expand storage and throughput capacity incrementally by adding iBOTs or aisles without disrupting operations. This flexibility means companies can grow their automation investment alongside rising demand, avoiding costly system replacements or downtime. Facilities can start with a single aisle and scale up over time to support greater throughput without impacting current workflows.

Labor Efficiency: By automating retrieval and delivery, Perfect Pick reduces the time employees spend walking or manually locating inventory. This results in up to an 8:1 reduction in person-hours, allowing fewer workers to achieve higher daily output. The system also lowers dependency on temporary labor, reducing recruitment and training challenges.

Space Optimization: Perfect Pick’s vertical racking design enables facilities to store more inventory in the same footprint, maximizing cubic utilization. This helps businesses avoid or delay costly warehouse expansions while increasing SKU capacity. Companies can reclaim valuable floor space for other operational activities while maintaining high-volume storage.

Rapid ROI: With an average return on investment in under 3.5 years, Perfect Pick delivers a compelling financial case for automation. Savings are achieved through reduced labor costs, improved throughput, and minimized space requirements. Many customers experience payback even faster during high-demand periods when manual processes would require additional staffing.

System Resilience: Unlike systems with centralized controls, Perfect Pick’s independent iBOTs eliminate single points of failure, ensuring continuous operations. If one iBOT requires maintenance, it can be removed relatively quickly from the system. Once removed, the remaining iBOTs continue fulfilling orders with minimal downtime. This distributed design provides built-in redundancy and keeps fulfillment moving even under unexpected conditions.

Chapter 6

Evaluating the High-Density AS/RS Landscape

Selecting the right AS/RS requires understanding the strengths of different automation types and how they align with operational needs. High-density AS/RS solutions, like Perfect Pick, offer unique advantages compared to other automation systems designed for different load types and workflows.

When evaluating automation options, it’s important to consider how high-density AS/RS compares to:

Heavy Pallet Load Systems: These systems are designed for bulk pallet movement and storage of large, heavy items. While effective for pallet-level handling, they lack the SKU-level access and picking speed of high-density AS/RS, making them less suitable for split-case or piece-picking fulfillment operations.

Smaller/Mini-Load Systems: Mini-load AS/RS typically handle small cartons or bins in a rack-supported structure. While similar in some ways to high-density AS/RS, they often rely on shuttle or crane systems that may create bottlenecks and limit simultaneous access to multiple storage locations. High-density AS/RS like Perfect Pick use independent iBOT robots for concurrent access and greater throughput.

Vertical Lift Modules (VLM): VLM systems provide automated vertical storage and retrieval of trays via an extractor. These systems are well-suited for low-to-medium volume applications. Still, they may be slower and less scalable for high-throughput fulfillment than a high-density AS/RS that allows parallel picking and retrieval.

Cube-Based Systems: Cube-based storage solutions stack bins in a grid with robots retrieving from the top layer. While space-efficient, they require bin relocation to access items below, creating delays for high-frequency SKUs. In contrast, high-density AS/RS designs provide direct access to every storage location, reducing retrieval times for fast-moving products.

Carousel Systems: Horizontal and vertical carousel systems rotate storage locations to a picking point. While effective for small parts storage, carousels can create sequential bottlenecks as only one item per carousel can be accessed at a time. High-density AS/RS systems support multiple simultaneous retrievals, offering higher throughput.

Each of these automation types serves specific operational goals. High-density AS/RS offers an optimal balance for operations requiring high-speed, SKU-level picking, space efficiency, and scalability without sacrificing accessibility.

Organizations evaluating automation should consider their current inventory and order profiles, future growth plans, and throughput targets. High-density AS/RS provides the flexibility, speed, and storage efficiency needed to meet these demands.

Chapter 7

Success Metrics and ROI

Perfect Pick’s real-world performance is proven across industries:

- Increased Throughput: Facilities process thousands of totes per hour, maintaining fast order cycles. For example, J. Knipper scaled to process over 3,000 daily orders using Perfect Pick, achieving same-day shipping targets and improving customer satisfaction.

- Labor Savings: Customers report 3x labor efficiency gains and reduced overtime requirements. Ingram Micro experienced significant reductions in labor costs while maintaining high throughput, enabling their sites to operate efficiently even with a leaner workforce.

- Space Efficiency: One customer consolidated 6,500 cubic feet of inventory into just 1,500 square feet using Perfect Pick. BioLegend leveraged Perfect Pick’s vertical storage to manage cold-storage inventory efficiently, freeing valuable floor space and improving operational safety.

- Scalable Growth: Sites processing up to 18,000 daily orders can scale capacity without infrastructure changes. Newegg relied on Perfect Pick’s modular scalability to handle peak-season order spikes while avoiding costly facility expansion.

- Faster ROI: Customers achieve payback in less than 3.5 years through labor, space, and throughput improvements. Across industries, companies have realized financial returns faster by combining Perfect Pick’s labor reduction, space savings, and increased throughput benefits.

These outcomes demonstrate Perfect Pick’s ability to improve operational performance and financial returns.

Conclusion

The Smart Choice for a Smarter Warehouse

Perfect Pick empowers fulfillment centers to meet today’s challenges while preparing for tomorrow’s growth. By combining scalable automation, high-speed picking, and intelligent software integration, Perfect Pick enables operations to increase throughput, reduce costs, and improve accuracy — all within existing footprints.

Take the next step toward transforming your warehouse. Contact OPEX today to schedule a personalized demo, request a custom ROI analysis, or speak with an automation expert to explore how Perfect Pick can drive measurable results for your business.

Other Resources You Might Find Helpful

Palm Beach County Tax Office

Automating Donation Processing for Nonprofits

Same-Day Delivery: Making It a Reality With Automated Sorting Systems

RMMI Streamlines Scanning Efficiency with OPEX® Falcon®+ One-Touch Scanners

Optimizing Your Warehouse Layout for Automation

Reducing Errors and Improving Accuracy With Automated Sorting in Logistics

Automating Invoice Processing for Energy Companies

Streamlining Operations: The Impact of Automation on Financial Institutions

Boosting E-Commerce Efficiency: The Role of Warehouse Automation

Improving Turnaround Times With Automated Document Processing

NEXT LEVEL AUTOMATION

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.