How AS/RS Supports Just-In-Time (JIT) Manufacturing

A Guide to Implementing Automation in Manufacturing Operations to Support JIT Principles

23 min read

60-Second Summary

Just-In-Time (JIT) manufacturing is all about efficiency, precision, and reducing waste, but maintaining a seamless flow of materials without excess inventory requires the right technology. That’s where automated storage and retrieval systems (AS/RS) come in. These advanced solutions optimize inventory management by ensuring materials are available exactly when needed, reduce operational costs by minimizing storage space and labor reliance, and enhance speed and accuracy by automating storage and retrieval processes for faster order fulfillment and leaner supply chains.

Introduction

In today’s fast-paced manufacturing environment, efficiency, precision, and cost-effectiveness are more critical than ever. Just-In-Time (JIT) manufacturing has emerged as a leading strategy for minimizing waste, improving production flow, and responding rapidly to customer demand. However, the success of JIT hinges on the ability to store, retrieve, and deliver materials with high accuracy and speed, a challenge that traditional storage methods often fail to meet.

This is where Automated Storage and Retrieval Systems (AS/RS) come into play. These advanced solutions streamline inventory management, reduce reliance on manual labor, and enhance operational efficiency, which makes them an ideal fit for JIT workflows.

In this eBook, we’ll explore how AS/RS supports JIT manufacturing, the business case for investing in automation, real-world case studies, and the latest technological trends shaping the future of warehouse efficiency.

Chapter 1

An Overview of Automation in JIT Manufacturing

Understanding Just-In-Time (JIT) Manufacturing

JIT manufacturing, or the Lean Production model, is a production strategy designed to improve efficiency by minimizing inventory levels and reducing waste, such as overproduction, excess storage, and inefficient processing. JIT focuses on producing inventory only when needed, without relying on surplus inventory.

This approach enables manufacturers to produce high-quality goods, increase efficiency, and lower overhead costs. However, JIT is susceptible to supply chain disruptions, requiring high supply chain visibility and supplier relationships.

Key principles of JIT manufacturing include:

- Demand-Driven Production: Ensuring that materials and components arrive precisely when needed to produce products on demand.

- Waste Reduction: Eliminating excess inventory and storage, overproduction, defects, and unnecessary handling costs.

- Continuous Improvement: Regularly refining processes to enhance efficiency and reduce lead times.

- Supplier Coordination: Strong collaboration with suppliers ensures timely delivery of materials and components.

The Role of Automation in JIT

Automation plays a critical role in the success of JIT manufacturing by enabling precise and efficient operations, providing several key benefits.

Enhanced Speed and Accuracy:

Automated systems ensure rapid retrieval and movement of materials, reducing manual handling and errors.

Real-Time Inventory Control:

Automated tracking and data analytics provide real-time insights into stock levels, preventing overstocking or shortages.

Predictive Maintenance:

AI-driven automation can anticipate equipment issues before they disrupt production, ensuring seamless operations.

Reduced Labor Dependency:

Robotics and automated systems decrease reliance on manual labor while improving productivity and consistency.

Integrating automation into JIT processes allows manufacturers to improve productivity, reduce downtime, and maintain lean inventory management in an efficient, cost-effective way.

Chapter 2

Understanding AS/RS Technologies and How They Are Used in JIT Manufacturing

The adoption of an AS/RS in JIT environments helps manufacturers meet production schedules and distribution needs, reducing excess inventory while ensuring that materials are available exactly when needed.

Introduction to Automated Storage and Retrieval Systems (AS/RS)

An AS/RS consists of automated mechanisms that retrieve and place inventory in designated locations within a confined system, such as cranes, shuttles, and robotic vehicles. These systems provide high storage density and operational efficiency by eliminating manual handling and searching. AS/RS are essential for optimizing warehouse operations, particularly in JIT manufacturing operations.

Some key functionalities of an AS/RS are:

- High-Density Storage: Utilizing vertical space and compact layouts to maximize warehouse space.

- Automated Picking and Retrieval: Reducing human error and accelerating material flow using robotics.

- Integration with Warehouse Management Systems (WMS): Ensuring seamless coordination between production and inventory systems through API integration.

- Scalability and Adaptability: Easily adjusting to fluctuating demand and production cycles with additional storage modules and robotics.

How AS/RS Supports JIT Principles

AS/RS play a crucial role in JIT manufacturing by ensuring materials and components are delivered accurately and when needed, reducing waste and improving efficiency. The core principles of AS/RS align seamlessly with JIT methodologies by:

Minimizing On-Hand Inventory

An AS/RS enables companies to maintain lean inventory levels by efficiently storing and retrieving items as needed while reducing the overall footprint required to store parts and raw materials.

Enhancing Operational Efficiency

Automated systems streamline the movement of goods and material flow, eliminating delays caused by manual processes.

Reducing Waste

AS/RS help ensure timely and accurate inventory management, preventing overproduction, reducing mistakes, and minimizing unnecessary storage costs.

Types of AS/RS Technologies and How They Support JIT

By integrating one or more of these AS/RS technologies into JIT manufacturing operations, companies can significantly improve inventory accuracy, reduce lead times, and enhance overall supply chain performance.

Goods-to-Person (G2P) Systems

Vertical Lift Modules (VLM)

Vertical Lift Modules (VLM) consist of an enclosed shelving system where trays are retrieved and delivered to an access point based on system requirements or an operator's request. VLMs eliminate the need for employees to walk through aisles, enhancing operational speed and accuracy. This technology is especially beneficial for JIT environments where quick and reliable access to small parts and lightweight components is crucial for assembly lines.

Horizontal and Vertical Carousels

Carousels, whether horizontal or vertical, are mechanized storage systems that use rotating shelves or bins to bring items directly to operators. This technology significantly reduces item retrieval time and improves picking accuracy, making them ideal for high-volume, fast-moving inventory. Horizontal carousels are well-suited for applications where space constraints limit vertical expansion, while vertical carousels efficiently use overhead space. Both solutions enable quick and organized access to components required in JIT manufacturing.

Mini-Load AS/RS

A mini-Load AS/RS is designed to handle small to medium-sized loads stored in totes, trays, or bins. These systems are capable of rapidly retrieving components, making them a critical asset in JIT manufacturing lines where frequent part retrieval is necessary. Mini-load AS/RS reduces reliance on manual labor by automating storage and retrieval, increasing picking accuracy and ensuring the continuous availability of parts for production processes.

Chapter 3

Making the Business Case for AS/RS in JIT Operations

To justify investing in an AS/RS for JIT manufacturing, companies must build a strong business case. AS/RS solutions offer compelling benefits, including cost reduction, improved space utilization, increased efficiency, better risk mitigation, and higher scalability and flexibility. To gain approval from shareholders and upper management, companies must present a clear return on investment (ROI) analysis and justify the long-term value.

ROI and Justifying Investment to Shareholders and Upper Management

An AS/RS provides tangible financial benefits, including cost savings, efficiency improvements, and risk mitigation. These systems reduce operational costs by minimizing the need for excessive manual labor, optimizing space utilization, and ensuring more accurate inventory management, ultimately reducing waste and improving order fulfillment speed.

Calculating the ROI involves analyzing the system implementation cost against the long-term financial benefits. Companies should present clear metrics such as reductions in item handling time, decreased labor costs, improved inventory accuracy, and minimized stockouts. A well-articulated ROI analysis will help stakeholders understand the long-term value of AS/RS and justify capital expenditures. The following factors will help justify your business case for automation:

Cost Reduction

One of the most immediate financial benefits of an AS/RS is cost reduction. These systems eliminate inefficiencies associated with traditional storage methods, leading to significant labor and inventory management savings. Businesses can reduce dependency on manual labor, lower payroll expenses, and minimize the risk of human error and injuries on the job.

Space Optimization

Traditional storage methods often require extensive floor space and inefficient racking systems that limit scalability. An AS/RS leverages vertical space too high for employees to access manually, allowing companies to store more inventory in a smaller, more compact footprint. This is particularly advantageous for facilities with space constraints or those seeking to avoid the costs associated with expanding real estate or creating additional production facilities.

Efficiency Gains

With improved picking accuracy and automation-driven workflows, businesses can meet customer demands more reliably while minimizing delays in production cycles. An AS/RS reduces the likelihood of misplaced or lost inventory by tracking items via software, ensuring that every component is accounted for and readily available when needed. This efficiency translates to lower operational costs and enhanced service levels.

Risk Mitigation

Manual storage and retrieval methods pose risks such as human errors, workplace injuries, item damage, and inventory mismanagement. An AS/RS minimizes these risks by automating critical processes, limiting the need to access high shelves and cluttered areas, and guiding inventory handling. This reduces the likelihood of accidents and ensures that inventory is tracked and handled correctly. With fewer accidents and errors, businesses can reduce liability costs and maintain compliance with safety regulations.

Scalability and Flexibility

Many AS/RS solutions are designed to accommodate changing business needs by offering modular and adaptable configurations. Companies can easily expand storage capacity, integrate additional automation components, and adjust system parameters to align with evolving production requirements.

Chapter 4

Overcoming Challenges in AS/RS Adoption for JIT

While an AS/RS offers substantial benefits, companies must address integration hurdles, cost concerns, workforce adaptation, and implementation strategies. Successfully overcoming these obstacles will allow businesses to fully leverage AS/RS and maximize efficiency in JIT manufacturing.

Common Challenges of AS/RS Adoption

Integration with Legacy Systems

One of the most significant challenges in adopting an AS/RS and any other automation technology is ensuring seamless integration with existing WMS and Enterprise Resource Planning (ERP) systems. Many companies operate with legacy software that may not immediately support an AS/RS, leading to compatibility issues.

To mitigate this challenge, businesses should assess their current system architecture and work with AS/RS providers that offer flexible, comprehensive integration solutions. API-driven connectivity, middleware, and phased deployment strategies can help bridge gaps between legacy systems and modern automation. Companies may also consider a pilot phase to test AS/RS compatibility with existing infrastructure before committing to a full-scale deployment.

Initial Investment Costs

The upfront costs associated with AS/RS implementation can be a major barrier for companies considering automation. These costs include procurement, installation, software integration, employee training, and service. Businesses must evaluate the ROI and long-term benefits of AS/RS investments rather than just initial expenses.

A well-documented ROI analysis can help justify AS/RS adoption to stakeholders. Factors such as reduced labor costs, improved order accuracy, lower operational expenses, and space optimization should be highlighted in financial projections. In many cases, companies experience significant cost savings and increased efficiency within the first few years of AS/RS deployment. Leasing options and financing programs offered by AS/RS vendors can help businesses manage initial capital expenditures more effectively.

Change Management

Transitioning to AS/RS requires a shift in workforce responsibilities and operational processes. Employees accustomed to manual storage and retrieval tasks may resist automation due to concerns about job security or unfamiliarity with new technologies. Effective change management strategies are crucial to addressing these challenges.

To facilitate a smooth transition, companies should implement structured training programs that equip employees with the necessary skills to operate and maintain AS/RS. Engaging the workforce early in the implementation process, communicating the benefits of automation, and providing hands-on training sessions can help reduce resistance and increase acceptance.

Rather than eliminating jobs, AS/RS often reallocates human labor to more strategic and value-added tasks, such as system monitoring, quality control, and process optimization. Communicating this shift to employees can foster a positive workplace culture that embraces technological advancements.

Implementation Best Practices

A phased implementation approach is one of the most effective ways to minimize disruptions while adopting AS/RS. Companies should start with a single warehouse or department before expanding the system company-wide. This allows teams to troubleshoot potential issues, refine processes, and collect performance data before scaling up.

Other best practices include:

- Defining Clear Objectives: Establishing key performance indicators (KPIs) and success metrics before implementation ensures that AS/RS adoption aligns with business goals.

- Vendor Collaboration: Working closely with AS/RS vendors and technology partners can help tailor solutions to meet specific business needs.

- Continuous Monitoring and Optimization: In post-implementation, businesses should continuously analyze and adjust AS/RS performance to improve efficiency and productivity.

Businesses can successfully implement AS/RS in JIT manufacturing by carefully managing integration, investment, workforce adaptation, and deployment strategies. Overcoming these challenges will result in improved operational efficiency, reduced costs, and enhanced scalability for long-term growth.

Chapter 5

Real-World Use Cases

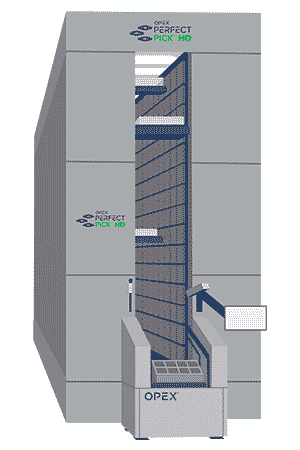

The real impact of AS/RS in JIT manufacturing is best demonstrated through practical applications. This chapter explores three case studies where the OPEX® Perfect Pick® High-Density AS/RS can transform operations in different industries: auto parts, manufacturing, and distribution. These examples illustrate how an AS/RS improves efficiency, accuracy, and scalability while reducing labor costs and bottlenecks.

Real-World Use Case

Manufacturing Industry: Transforming Manufacturing Warehouses

Manufacturing warehouses face increasing pressure to enhance efficiency, accuracy, and scalability while maintaining low costs. Manual picking and storage workflows lead to bottlenecks during peak seasons, labor shortages, and increased risks of errors that disrupt production schedules. Excessive walking between pick locations further extends fulfillment times, making it difficult for manufacturers to maintain JIT principles.

OPEX Perfect Pick has addressed these challenges by implementing a goods-to-person model, where iBOTs autonomously retrieve and deliver inventory totes to ergonomic pick stations. This automation significantly reduces dependency on manual labor and improves picking accuracy, ensuring that raw materials and components arrive precisely when needed for production. Prioritizing high-frequency SKUs and optimizing inventory slotting allows manufacturers to minimize production downtime, reduce waste, and maintain a seamless flow of goods.

Real-World Use Case

Automotive Industry: Modernize Auto Parts Warehousing

The auto parts industry handles a diverse inventory of stock-keeping units (SKUs), ranging from small, lightweight components to large, heavy items. Warehouses must meet the needs of both B2B and B2C customers while adhering to tight delivery timelines. Traditional order fulfillment practices often rely on manual workflows for receiving, storing, picking, and shipping. These processes, while functional, are time-consuming and prone to inefficiencies, especially when scaling operations or managing emergency orders.

Implementing Perfect Pick has transformed auto parts fulfillment by leveraging high-density vertical storage to optimize space and reduce operational bottlenecks. The system’s iBOT® technology ensures rapid retrieval and delivery of inventory, minimizing employee travel time and physical strain. Perfect Pick integrates seamlessly with a WMS and existing software, allowing real-time tracking of inventory and priority slotting of high-demand items. Automating order fulfillment allows auto parts distributors to improve accuracy, reduce labor costs, and fulfill time-sensitive repair shop requests without disrupting ongoing operations.

Real-World Use Case

Distribution: Enhancing Warehouse Distribution Centers

Distribution centers manage thousands of SKUs and experience high labor challenges, particularly during seasonal peaks. Traditional workflows rely on employees walking considerable distances to manually pick items, leading to delays, increased error rates, and rising labor costs.

With the integration of OPEX Perfect Pick, distribution centers have transitioned to automated order fulfillment that eliminates unnecessary employee travel and accelerates throughput. The system’s high-density vertical storage enables businesses to optimize space, while its robotic iBOTs ensure quick and precise picking. Operators receive inventory at ergonomic stations, reducing physical strain and improving overall accuracy with guided picking technologies such as pick-to-light. By implementing Perfect Pick, distribution centers have reported reduced dependency on seasonal hires, lower operational costs, and enhanced order fulfillment speed.

Chapter 6

Future Trends for AS/RS Use in JIT Manufacturing

As global supply chains become more complex, businesses seek innovative solutions to enhance efficiency, accuracy, and scalability. Emerging trends such as AI, Internet of Things (IoT) integration, robotics, sustainability initiatives, and supply chain resilience are redefining how an AS/RS can operate within JIT environments. This chapter explores the key trends driving the next generation of warehouse automation and inventory management.

AI and Predictive Analytics

AI potentially enhances AS/RS technology by enabling predictive analytics and intelligent decision-making. AI-powered software can analyze historical inventory data, forecast demand patterns, and optimize stock levels to minimize waste and maximize efficiency. Predictive analytics can anticipate fluctuations in demand, allowing warehouses to proactively adjust inventory allocation, reducing stockouts and overstocking.

IoT Integration and Smart Warehousing

Integrating the Internet of Things (IoT) into AS/RS systems is paving the way for smart warehousing. IoT-enabled sensors, RFID tags, and connected devices provide real-time data on inventory location, equipment status, and environmental conditions. These connected systems enable greater visibility and control over warehouse operations, ensuring seamless coordination between supply chain partners. This helps support JIT goals of strong supplier relationships to ensure materials are acquired in a timely matter.

Robotics and Advanced Automation

The deployment of advanced robotics in AS/RS technology is enhancing efficiency and precision in warehouse management. Next-generation robotic picking systems utilize vision recognition, AI-driven navigation, and adaptive learning to handle a wide range of SKUs with minimal human intervention. Autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) are increasingly adopted to assist human operators in picking, packing, and replenishing tasks. These advancements not only reduce reliance on manual labor but also enable 24/7 operations, supporting JIT principles for continuous efficiency improvements.

Sustainability and Green Logistics

Sustainability is becoming a critical factor in JIT and automation technologies. Companies focus on energy-efficient automation, reducing their carbon footprint through optimized resource utilization. Modern AS/RS systems are designed to minimize environmental impact with low-energy consumption components, regenerative power systems, and space-efficient storage solutions. The adoption of recyclable materials and eco-friendly packaging further supports sustainability, waste reduction, and efficiency goals in JIT manufacturing.

Supply Chain Resilience and Risk Mitigation

Recent disruptions in global supply chains have highlighted the need for resilient and adaptable logistics solutions. AS/RS are key in enhancing supply chain resilience by improving inventory control, reducing lead times, and ensuring rapid response to market fluctuations. Decentralized warehousing strategies and micro-fulfillment centers can help mitigate risks associated with single-source dependencies. The ability to rapidly scale operations and adjust inventory distribution through AS/RS provides JIT operations with the agility needed to navigate uncertainty.

Chapter 7

OPEX's AS/RS Solutions for JIT Manufacturing Operations

OPEX provides tailored AS/RS solutions for JIT operations that strive to optimize warehouse workflows, reduce costs, and enhance operational precision. This chapter explores how OPEX’s AS/RS offerings, Infinity® and Perfect Pick HD, are engineered to meet the evolving demands of modern supply chains.

OPEX Systems' Seamless Integration with JIT Manufacturing Operations

OPEX’s AS/RS solutions are designed to seamlessly integrate with JIT manufacturing workflows, supporting businesses in their pursuit of lean, efficient, and responsive supply chains.

How OPEX systems enhance JIT workflows:

- Optimized material flow: Ensure raw materials and components are available precisely when needed, eliminating excess storage space by utilizing compact, dense-storage systems.

- Inventory control: Reduces stockouts and overstocking by maintaining real-time inventory accuracy and keeping items secure.

- Operational flexibility: Adapts to changing demand conditions, supporting scalability without sacrificing efficiency.

OPEX AS/RS Technologies

Infinity AS/RS: High-Density, Modular Storage and Fast Retrieval

Infinity AS/RS is a cutting-edge solution that maximizes storage capacity while ensuring rapid inventory retrieval. This system utilizes autonomous iBOT robots, capable of transporting industry leading, 90-pound (40.8 kilogram) payload, to navigate a high-density storage grid, retrieving and delivering inventory with exceptional accuracy. Infinity AS/RS leverages vertical space while working around obstructions, enabling businesses to store more inventory in a compact footprint without needing facility expansion.

Infinity benefits manufacturers with diverse SKU portfolios, high-turnover inventory, and fluctuating demand patterns. Its rapid retrieval capabilities ensure that raw materials and components are available exactly when needed, aligning with the core principles of JIT manufacturing.

Key benefits of Infinity AS/RS:

- Scalability and Modularity: Businesses can expand their system as demand increases without major infrastructural changes.

- High-Density Storage: Optimizes warehouse layouts using multi-level, triple-deep tote storage grids.

- Automated Inventory Management: Ensures real-time stock tracking and seamless integration with WMS and other software systems.

- Energy-Efficient Operations: Reduces energy consumption through intelligent power management and self-charging iBOT technology.

Perfect Pick: Goods-to-Person Efficiency for Rapid Order Fulfillment

Perfect Pick and Perfect Pick HD (High-Density) are advanced AS/RS solutions that enhance goods-to-person workflows, significantly improving warehouse productivity. The systems utilize iBOTs to transport inventory totes to ergonomically designed pick stations within an aisle, minimizing worker travel time and reducing physical strain. Each iBOT robot can carry a payload of 80 pounds (36.29 kg).

This approach accelerates item handling while maintaining high levels of accuracy. Perfect Pick is ideal for manufacturing warehouses, distribution centers, and e-commerce fulfillment hubs, requiring fast, precise, and scalable order processing.

Key benefits of Perfect Pick and Perfect Pick HD AS/RS:

- Rapid Order Processing: Optimized picking workflows reduce fulfillment time and improve customer satisfaction.

- Error Reduction: Automated order sequencing and pick-to-light technology minimize human errors.

- Flexible and Configurable: Accommodates a variety of inventory types, including small parts and larger components.

- Seamless WMS Integration: Enhances inventory visibility and ensures real-time order tracking.

Conclusion

The integration of AS/RS technology into JIT manufacturing represents a significant leap forward in operational efficiency, accuracy, and scalability. Throughout this eBook, we have explored how AS/RS align with JIT principles, enhances inventory management, and supports businesses in adapting to evolving supply chain demands.

Key Takeaways

- AS/RS Enhances JIT Manufacturing: AS/RS support lean manufacturing strategies by reducing inventory waste, improving retrieval times, and ensuring the precise availability of materials.

- Cost Savings and ROI: Companies adopting AS/RS solutions experience reduced labor costs, improved space utilization, and higher order accuracy, all contributing to a strong ROI.

- Technological Advancements: AI-driven automation, IoT integration, robotics, and predictive analytics are transforming AS/RS capabilities, making them smarter and more adaptable.

- Real-World Success: Case studies in auto parts, manufacturing, and distribution sectors demonstrate how AS/RS optimizes workflows and drives operational excellence.

- OPEX’s Leadership in AS/RS: OPEX’s Infinity and Perfect Pick solutions provide flexible, scalable, and efficient automation tailored for JIT environments.

The Path Forward

Businesses that invest in AS/RS today are not only improving current operations but also future-proofing their supply chains against disruptions, labor shortages, and shifting market demands. Leveraging automation allows companies to achieve the efficiency and precision required to remain competitive in an increasingly digitalized world.

If your organization is ready to enhance its JIT manufacturing and warehouse operations with cutting-edge AS/RS solutions, OPEX can help. Our team of experts is available to discuss your specific needs, provide detailed system demonstrations, and guide you toward the best automation strategy for your business.

Contact OPEX today to learn more about how our AS/RS solutions can transform your operations and drive long-term success.

Other Resources You Might Find Helpful

NEXT LEVEL AUTOMATION

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.