Integrated Software Suite for Simplified, Efficient Order Fulfillment

Streamline Order Fulfillment with Cortex® S2O™

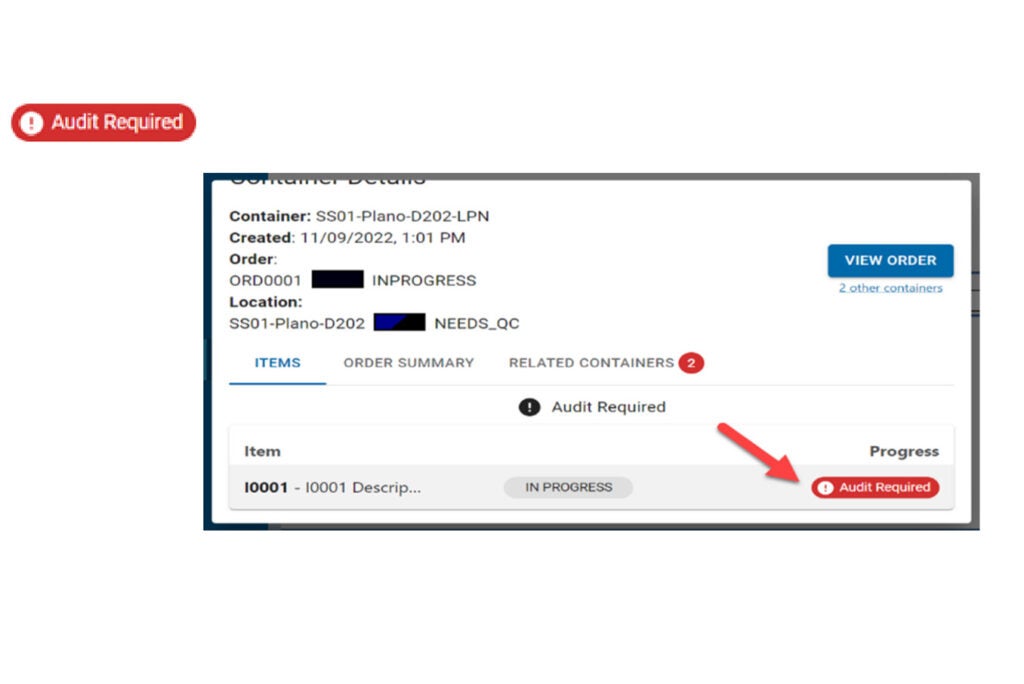

Cortex S2O enhances order accuracy through integrated scanning and verification workflows across its 3-Scan Sweep, Touchless, and Focused Scan-In/Out modes. It provides real-time feedback via haptic scanner vibrations and visual Pick-to-light (PTL) cues to alert sweepers of errors or order conditions such as stale or short orders. Additionally, Cortex S2O conducts quality control audits and guides operators through resolution workflows for issues like missing items or audit-required bins, significantly reducing human error and increasing fulfillment integrity.

Yes, Cortex S2O automatically recognizes and supports split orders when items exceed a single bin’s capacity. The system displays on-screen prompts and uses PTL indicators to guide sweepers through each component of the split order, ensuring all related bins are handled and processed correctly. It supports continued scanning of associated bins until the full order is completed, improving efficiency for multi-bin fulfillment.

Cortex S2O provides operational analytics and real-time visibility into warehouse performance. It offers automated reports that track order consolidation speed, operator productivity, and order dwell times. This enables warehouse leaders to make data-driven decisions that optimize labor use, identify bottlenecks, and ensure Service-level Agreement) SLA compliance. These analytics are accessible via a web-based administrative portal and support up to 50 operators and 20 managers simultaneously.

Cortex S2O is designed to simplify system integration by acting as the orchestrator between sortation hardware and fulfillment software. It supports multiple communication methods, including database-to-database and flat file transfers, and integrates directly with WMS/OMS systems. It can also manage multiple sorters simultaneously (up to 12 systems) and includes an override function for manual bin reassignments when needed.

If an order is short (i.e., missing items), Cortex S2O prompts the S2O Sweeper to acknowledge the short order via scanner input. In both single and split short orders, the process involves scanning the affected location, removing the short order bin, replacing it with an empty bin, and updating Cortex via scans. In Touchless and Anonymous Sweep modes, the system may automatically initiate scan-out workflows and replace the shorted bin with an anonymous container, keeping operations moving without disruption.

Core Software Features

Cortex S2O delivers a comprehensive suite of core features that streamline warehouse operations. It automates order bin assignment, optimizing placement by order attributes like weight and volume, and supports split-bin logic. Operators interact through a mobile, wrist-mounted interface for scanning, bin replenishment, and sortation management. Real-time analytics report on order status, fulfillment speed, and productivity, while built-in quality control audits ensure accuracy. The system integrates easily with WMS/OMS environments for seamless order flow and inventory tracking.

Functional Operation Modes

S2O offers flexible operation modes to support a variety of workflows and user experience levels. The 3-Scan Sweep Mode guides users through bin replacement with built-in error-proofing. Touchless Mode reduces scanning requirements for more efficient operation. Focused Scan-In and Scan-Out streamline partial workflows, while Anonymous Sweep Mode allows operations without container ID tracking. These modular options adapt easily to different fulfillment models, workforce skill levels, and process automation needs.

User Experience Enhancements

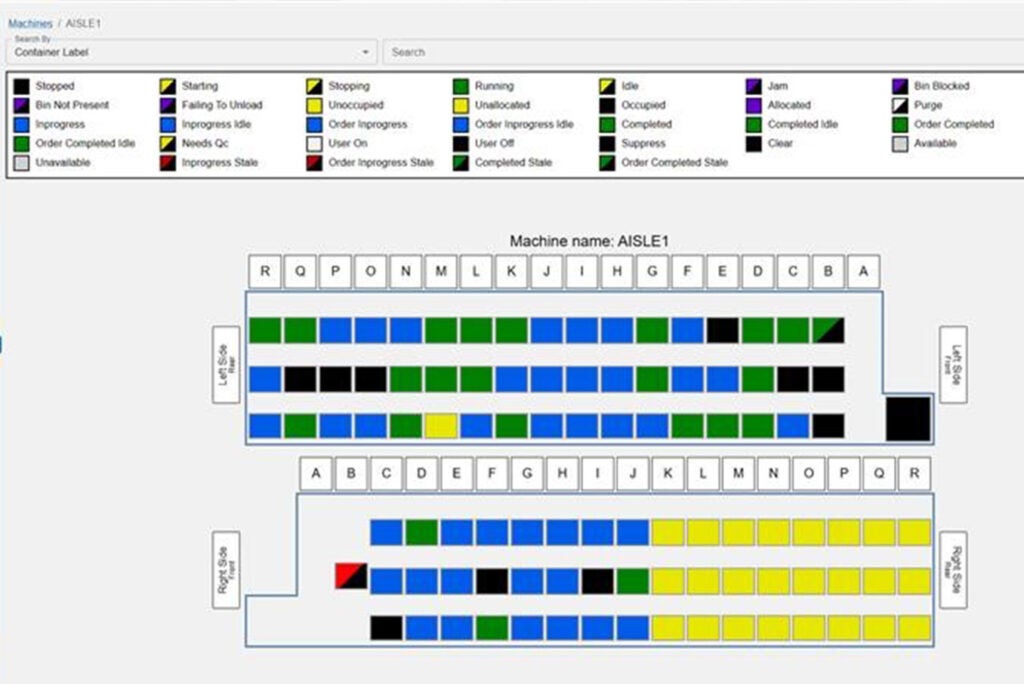

To boost usability and adoption, S2O includes tactile and visual feedback mechanisms. PTL (Pack-to-Light) indicators use color-coded, blinking lights to display bin and order status such as completed, jammed, or needing audit. Scanner haptics, short, medium, and long vibrations, help operators confirm successful or erroneous actions instantly. These enhancements minimize training time and improve task clarity for operators, making S2O highly accessible across diverse teams and skill levels.

Additional Features and Capabilities

Beyond core functions, S2O includes a suite of advanced tools to improve operational control and security. Manual overrides allow item reassignment; diagnostic and troubleshooting tools assist with order errors. A web-based administrative portal supports configuration, user access, and monitoring. The system supports up to 70 users with role-based access, Active Directory/LDAP integration, and TLS 1.3 encryption. Annual version updates and compatibility with customer scanners make it both secure and adaptable.

Find Out How Cortex S2O Can Improve Your Operations

Improving Accuracy, Efficiency, and Scalability Across Warehouse Operations

Order Accuracy Improved Order Accuracy and Fewer Returns

Automated quality audits, error notifications, and PTL-guided actions catch issues before orders ship. This dramatically reduces mis-picks and incomplete shipments, helping protect brand reputation and customer satisfaction.

Flexible Integration Seamless Tech Adoption and ROI Confidence

The flexible, plug-and-play integration with WMS/OMS platforms means warehouses avoid costly custom development. This simplifies implementation, lowers upfront IT investment, and accelerates ROI—alleviating fears of integration disruption or sunk costs.

Scalable Architecture Growth Without Disruption

S2O’s scalable design accommodates increased order volume, bin configurations, and user access as operations grow. This futureproofs investment and eliminates the need for major process overhauls, solving concerns about long-term system obsolescence.

User-Empowerment Empowered Workforce and Lower Training Overhead

Intuitive user interfaces and clear PTL indicators make training fast and easy—even for less tech-savvy workers. This helps overcome resistance to change and ensures smooth adoption across a multigenerational workforce.

Discover How OPEX Has Impacted Other Operations

Palm Beach County Tax Office

Automating Donation Processing for Nonprofits

Same-Day Delivery: Making It a Reality With Automated Sorting Systems

RMMI Streamlines Scanning Efficiency with OPEX® Falcon®+ One-Touch Scanners

Optimizing Your Warehouse Layout for Automation

Reducing Errors and Improving Accuracy With Automated Sorting in Logistics

Automating Invoice Processing for Energy Companies

Streamlining Operations: The Impact of Automation on Financial Institutions

Boosting E-Commerce Efficiency: The Role of Warehouse Automation

Improving Turnaround Times With Automated Document Processing

NEXT LEVEL AUTOMATION

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.