Security Considerations in Retail Warehouses (and How to Overcome Challenges with Automation)

15 min read

60-Second Summary

Modern warehouse environments face security challenges beyond traditional concerns for physical theft. The interconnected nature of warehouse operations creates vulnerabilities in both digital and physical systems. Data integrity, cyberattacks, and threats to business continuity are substantial risks, adding to warehouse operations’ need for comprehensive security. Automated solutions have emerged as a powerful response to these evolving threats, offering enhanced security through reduced human touchpoints, secure audit trails, restricted physical access, and unprecedented inventory visibility. This blog will explore the various digital and physical challenges retail warehousing operations face and how they can be addressed with automation.

Introduction

Modern warehouses face a complex web of security threats, both physical and digital, that can disrupt operations, compromise customer data, and impact the bottom line. With the average cost of a data breach reaching a record $4.88 million globally and $3.91 million in retail sectors, security has become a top priority for warehouse operations managers and logistics directors alike. Additional risks such as loss of customer trust, long recovery periods, and potential settlements ranging from $30-$50 million drastically increase the urgency for secure retail operations.

As warehouses become increasingly connected and automated, they present unique security challenges that traditional solutions struggle to address. Within this challenge lies an opportunity: automation technologies that offer effective solutions to modern warehouse security problems.

The Security Landscape of Modern Warehousing

Modern retail distribution centers function as complex hubs of activity, integrating sophisticated technology systems with physical operations to meet the intense demands of e-commerce, omnichannel retail, and complex global supply chains. This new standard of warehousing presents more complex security concerns than only physical break-ins or theft. Sophisticated cyberattacks, compromised IoT devices, and access control challenges pose major threats to not only interconnected warehouses but to virtually all global organizations.

Digital Security Challenges in Warehousing

The warehouse digital transformation offers substantial benefits but also creates new vulnerabilities with potential cybersecurity threats that can negatively impact operations.

Data Integrity and Confidentiality

Warehouse operations generate and store massive amounts of sensitive data consisting of customer information, order details, and proprietary data. Protecting this data is critical for compliance with regulations like GDPR and CCPA and maintaining customer trust. If data integrity is compromised, it can lead to incorrect shipments, inventory discrepancies, and damaged customer relationships.

Cyberattacks and Threats

Retailers face increasingly sophisticated cyber threats, from ransomware attacks that encrypt valuable data to industrial espionage targeting proprietary information. As warehouses adopt more connected technologies, they present more attractive targets for cybercriminals. Relying on outdated operating systems with unpatched vulnerabilities makes organizations 3.4X more likely to experience a cyberattack

Business Continuity Risks

Interconnected supply chains are the new operating standard with warehouse management systems (WMS) being mission-critical infrastructure. A security breach that takes these systems offline can completely halt operations, preventing order fulfillment, inventory management, and shipping. Brief disruptions can have catastrophic financial implications for warehouses operating on thin margins or just-in-time models .

Third-Party Integrations Risks

Modern warehouses rarely operate as islands. They connect with carrier systems, customer platforms, supplier networks, and more. Each of these connections could be a potential entry point for security threats. Without proper security protocols for these integrations, warehouses may inadvertently expose their systems through trusted connections, allowing attackers to bypass perimeter defenses.

Inventory Vulnerabilities

Warehouses handle increasingly valuable and diverse products, from electronics and pharmaceuticals to luxury goods, making them attractive targets for both internal and external theft. Traditional inventory systems that rely on periodic cycle counts and manual inventory tracking often discover losses too late to identify the source, creating accountability gaps that can be repeatedly exploited.

Physical Security Challenges in Warehousing

Despite evolving cybersecurity concerns, physical security remains a fundamental challenge for retail warehouse operations. Modern warehouses face several critical physical security challenges:

Visibilty Limitations

One of the most persistent physical security challenges in warehouses is simply knowing when a loss has occurred. With thousands of SKUs moving through complex fulfillment processes, identifying the exact point of loss - whether through damage, misplacement, or theft - becomes extremely difficult. This lack of visibility not only hampers loss prevention efforts but also makes it challenging to implement targeted security improvements.

Unresricted Access

Modern warehouses face significant challenges in controlling who has access to which inventory areas. As operations scale, managing authorization for dozens or hundreds of employees across various zones becomes increasingly complex. Without automated inventory systems with user access controls, warehouses must choose between operational efficiency (broad access) and security (restricted access).

Chain of Custody and Retail Shrink

Maintaining a verifiable chain of custody for inventory and high-value items presents significant challenges. Each manual handoff in the supply chain creates an opportunity for error, loss, damage, or theft. The National Retail Federation National Retail Federation found in 2023 that shrink has caused a collective global loss of $112 billion for retail companies, with shrink increasing by 1.6% YoY. Shrink causes include employee theft, administrative errors, vendor fraud, damage, and shoplifting, leading to reduced profit margins, price increases, and operation cutbacks. Internal warehouse theft alone has cost US companies nearly $16 billion per year.

How Automation Addresses Digital Security

Automation technologies offer powerful solutions to many digital security challenges:

Limited Software Access

Automated systems minimize the need for human interaction with warehouse software through user access controls, reducing opportunities for social engineering attacks or insider threats. With fewer people requiring full access to sensitive systems, security becomes easier to maintain and track.

Automated Anomaly Detection

Advanced automated systems can leverage AI and machine learning to detect unusual patterns that might indicate a security breach. Unusual inventory movements, atypical system access, or unexpected data transfers can trigger immediate alerts before significant damage occurs.

Secure API Integrations

Modern automation solutions feature secure, standardized API integrations that reduce the risk of vulnerabilities in data transfers between systems. This creates a more controlled environment for information to flow throughout warehouse operations.

Enhanced Audit Trails

Automated systems create detailed, tamper-resistant logs of all access, actions, and transactions. These audit trails provide crucial forensic information in the event of a security incident and serve as powerful deterrents to insider threats.

How Automation Enhances Physical Security

Automation offers substantial benefits to physical warehouse security in addition to improving cybersecurity.

Restricted Physical Access to Inventory

Automated storage and retrieval systems (AS/RS) and goods-to-person (GTP) systems physically secure inventory in totes or trays within racking structures that only robots or mechanisms can access. This dramatically reduces opportunities for theft, as human workers never need to enter main storage areas. All interactions with the system and software are tracked and can be limited with user access controls.

Reuduced Manual Handling

AS/RS minimize manual handling and item retrieval, significantly reducing opportunities for both theft, loss, and accidental damage . Items can move directly from receipt to storage to shipping with minimal human interaction. Automated sorting systems also minimize the need for manual item handling, especially as they are integrated with more complex automation integrations such as conveyors or robotic arms.

Precise Inventory Control

AS/RS and GTP systems can connect to a WMS and maintain accurate inventory counts as system operators fulfill orders or replenish inventory. Discrepancies between expected and actual inventory levels become immediately apparent, allowing for immediate investigation of any potential theft or loss. AS/RS and GTP systems allow for automated cycle counting and randomized inventory checks, helping to keep inventory and high-value merchandise secure and accounted for.

Enhanced Tracking Capabilties

Modern automation solutions and software track material flow and individual item movement throughout the warehouse with precision that manual systems cannot match. This creates an unbroken chain of custody for high-value or sensitive items.

OPEX® Automated Solutions Designed for Warehouse Security

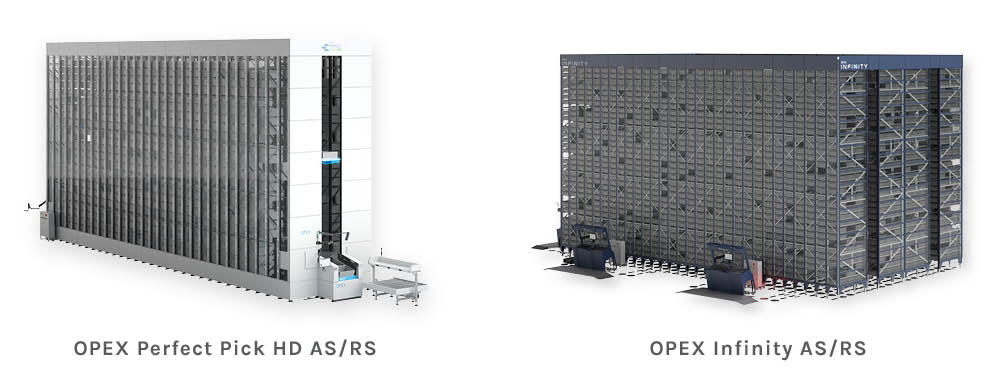

OPEX® provides secure warehouse automation solutions that address both physical and digital security challenges. Perfect Pick® and Infinity® AS/RS physically secure inventory within enclosed structures where only iBOT®robots can access stored items, dramatically reducing theft opportunities while creating a secure chain of custody for all inventory movements.

Detailed Tracking and Inventory

OPEX's Cortex® software platform powers the Perfect Pick and Infinity systems, accurately tracking inventory movement and communicating data back to the WMS. Cortex provides operators with guided item picking and replenishment, reducing mishandling and incorrect item placement and helping to prevent shrink and loss.

Reduced Human Touchpoints

With OPEX's goods-to-person systems, employees work at ergonomic workstations where items are delivered directly to them. This eliminates the need for workers to enter storage areas, dramatically reducing opportunities for theft or unauthorized access to inventory.

Integration with Existing WMS and Security Systems

OPEX solutions integrate seamlessly with existing warehouse security infrastructure, including WMS systems, access control, and security monitoring platforms. This ensures a cohesive approach to security across both automated and non-automated warehouse functions.

The Future of Secure Warehouse Through Automation

Automation will continue to play a crucial role in warehouse security strategies as threats continue to evolve. Forward-thinking warehouse operations managers and logistics directors are already leveraging automation not just for operational efficiency, but as a cornerstone of their security approach. Addressing both physical and digital security challenges through automation allows warehouses to protect assets, maintain data integrity, and build customer trust in an increasingly complex threat landscape.

Ready to Enhance Your Warehouse Security?

Contact OPEX today for a personalized assessment of how our automated solutions can address your specific security challenges while improving operational efficiency. Our team of experts will work with you to identify vulnerabilities and develop a tailored approach to warehouse security through automation.

Want to Learn More?

Other Resources You Might Find Helpful

Legastat: When Flatbed Scanning is NOT Enough

Taking on Wisconsin Department of Transportation DMV’s Digital Transformation

OPEX® Falcon+® RED® One-Touch Scanning Envelope Opener

Konica Minolta’s Competitive Edge: Streamlining Document Workflows with OPEX® Technology

The Imagine Group: Accelerating the Data Entry Process for Returned Mail with a Solution from OPEX® and CPT

Portsmouth, VA Treasurer’s Office Goes from Cost Center to Revenue Center

Built for Compliance: How Modern Scanning Systems Deliver Operational Excellence

Leon County Supervisor of Elections Overhauls Its Manual Document Process, Saving Money for Taxpayers

SPS and OPEX® Falcon+® RED® Document Scanners Provide Digitization at Sanitas

San Bernadino County Falcon+ Video

NEXT LEVEL AUTOMATION

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.