Warehouse Automation 2025: The Complete Guide to Cutting Costs and Boosting Efficiency

A comprehensive guide to the latest automation technologies and how to successfully integrate them with warehouse operations.

25 min read

60-Second Summary

Labor shortages, space constraints, and rising costs have dominated logistics conversations over the past several years. This ebook is your roadmap to a smarter, more agile, and efficient operation. In this comprehensive guide, we’ll introduce you to the transformative potential of automated warehouse systems, demonstrating how modern solutions can significantly reduce labor reliance, enhance throughput, and reclaim valuable floor space. We’ll explore real-world use cases and discover how automated systems help companies meet shifting demand while staying resilient. Whether you’re struggling with operational inefficiencies or planning for future growth, this guide breaks down the technology, benefits, and implementation strategies you need to make confident decisions.

Introduction

The warehousing and logistics industry continues to face unprecedented challenges and opportunities. Economic fluctuations, evolving consumer behaviors, rising labor costs, and rapid technological advancements have created a landscape where traditional warehousing methods no longer suffice. Decision-makers and operational leaders in warehousing are increasingly recognizing automation as a crucial solution to remain competitive, efficient, and profitable.

In this guide, you’ll discover actionable insights and detailed practical implementation strategies to maximize your return on investment and smoothly transition your warehouse operations into a highly automated, efficient, and future-proof environment.

Chapter 1

The Current State of Warehouse Automation

The warehousing landscape has evolved significantly, driven by technological advancements, shifting market demands, and rising operational pressures. In its 2025 Annual Industry Report, MHI found that some of the most impactful supply chain trends include inflation, economic uncertainty, workforce and talent shortages, supply chain resiliency, and inventory challenges.

Based on industry findings, what was once considered cutting-edge is now becoming standard practice, with adoption rates soaring across sectors. Understanding the current state of warehouse automation is crucial for making informed decisions on future investments.

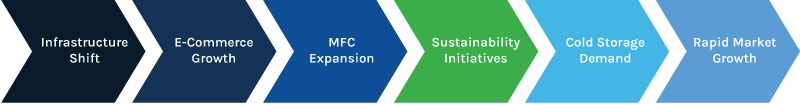

Key Market Trends and Insights

Infrastructure Shift:

There’s a clear movement away from rigid, fixed infrastructure toward more adaptable, scalable systems that can be reconfigured and scaled as needs change. Tightly integrated solutions that combine hardware, robotics, AI, and software are now the status quo.

E-commerce Growth:

The surge in online shopping has intensified the demand for efficient warehouse automation solutions to handle high volumes and fast delivery schedules. E-commerce revenue is projected to reach $5 billion in 2025, growing to $6.5 billion by 2029 (Statista).

Micro-Fulfillment Expansion:

Increased adoption of localized micro-fulfillment centers (MFCs) enables quicker deliveries and enhances customer experience while reducing transportation costs. The MFC market is projected to reach $9.39 billion in 2025 at a compound annual growth rate (CAGR) of 44.5%, driven by demand for same-day and next-day delivery (The Business Research Company).

Sustainability Initiatives:

Growing sustainability initiatives are leading warehouses to adopt energy-efficient and environmentally responsible automation solutions, enabling them to achieve reduced emissions and other energy efficiency goals.

Cold Storage Demand:

Growth in pharmaceuticals and perishable goods is fueling investments in cold storage facilities and automation solutions that can handle cold storage.

Market Growth:

The global warehousing market is projected to grow at a CAGR of 8.1% from 2024 to 2030, powered by technological innovations and expanding global trade (Grand View Research).

Technology Trends Shaping Warehouse Automation

AI and Machine Learning (ML) Adoption:

Warehouse operations look to leverage AI and ML to enhance inventory management, improve forecasting accuracy, and optimize warehouse operations. 51% of MHI’s survey respondents expect AI technologies to provide companies with a competitive advantage or disrupt the industry within the next 10 years, with 16% of organizations being unlikely to adopt AI within the next five years (MHI).

Predictive Analytics:

Investments in predictive analytics are expected to increase significantly to proactively manage inventory, resource allocation, and anticipate customer demand. 80% of 3PLs are actively investing in predictive analytics for supply chain operations, while 91% of organizations overall consider AI and predictive analytics essential within the next two years (Acropolium).

Robotics Innovations:

Operations’ use of robotics, such as AMRs, AGVs, and robotic picking systems, is steadily growing to significantly boost warehouse efficiency and safety. Experts anticipate that robotic shipments will increase by 50% annually through 2030, with warehouse automation expanding by more than 10% each year. (McKinsey and Company)

Top Challenges Facing Warehouses and Supply Chains

Labor Constraints:

Labor remains a top challenge for warehouses globally. Persistent labor shortages and rising costs prompt organizations to adopt automation to maintain operational efficiency. As of January 2025, 52% of HR leaders reported slow hiring as a cost-saving measure (Gartner). Talent shortages and hiring or retaining labor are rated extremely challenging by 45% and 52% of companies respectively (MHI 2025 Annual Industry Report).

Adoption Barriers:

Complex integration of new automation systems with existing technologies and software restricts automation adoption, limiting future growth and overall efficiency. The top barriers restricting automation adoption are the lack of a budget, a clear business case, and an understanding of technology (MHI 2025 Annual Industry Report).

Role of Human Workers:

Many companies have concerns about automation displacing human workers. Rather than replace humans entirely, many successful implementations focus on creating collaborative environments where technology handles routine tasks while humans manage exceptions and complex decision-making.

Rising Real Estate Costs:

Warehouse real estate costs for both greenfield and brownfield sites are at a premium, making it essential for businesses to use space as efficiently as possible.

Customer Expectations:

Customer expectations continue to put significant pressure on businesses to meet the demand for fast, error-free deliveries. One of the top challenges 43% of companies report is customer demands (MHI 2025 Annual Industry Report).

Cybersecurity Concerns:

As warehouses become increasingly digitalized and interconnected, there is an enhanced need for secure and reliable data protection measures.

Talent shortages are rated extremely challenging by 45% of companies. (MHI 2025 Annual Industry Report)

52% of HR leaders reported slow hiring as a cost-saving measure. (Gartner)

Top automation adoption barriers are lack of a clear budget, business case, and technology understanding. (MHI 2025 Annual Industry Report)

43% of companies report customer demands as a top challenge. (MHI 2025 Annual Industry Report)

Automation as an Essential Solution

These prevailing trends and challenges underscore the need for warehouse automation. Companies that adopt automated solutions can achieve significant efficiency improvements, substantial cost savings, and a competitive advantage in an increasingly complex market. Automation enables businesses to effectively manage labor constraints, optimize space utilization, minimize errors, and meet rapidly evolving customer expectations, all while maintaining sustainability and security.

Chapter 2

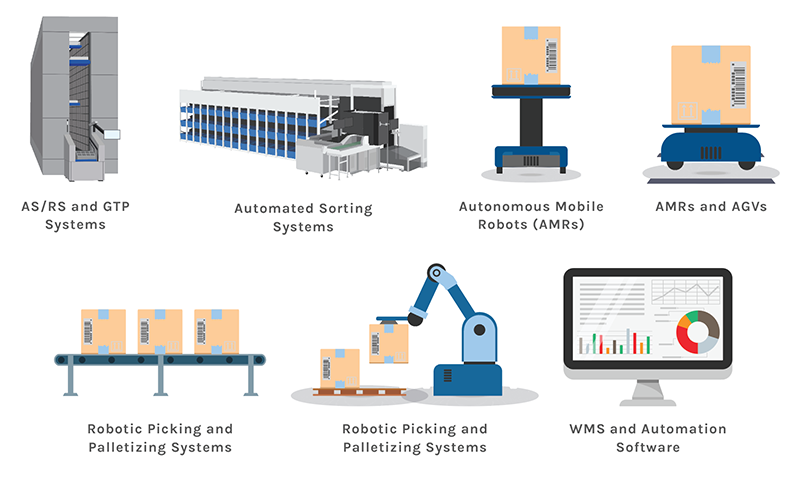

Core Warehouse Automation Technologies

The foundation of modern warehouse automation lies in a suite of integrated technologies that work together to optimize operations. Understanding these core technologies, their capabilities, and how they complement each other is essential for building an effective automation strategy. This chapter provides a comprehensive overview of the primary warehouse automation technologies driving efficiency and cost savings in 2025.

Automated Storage and Retrieval Systems (AS/RS)

Automated storage and retrieval systems (AS/RS) are computer-controlled systems that place and retrieve inventory from totes, trays, bins, or cartons within a racking structure using robotics. There are many types of AS/RS, with goods-to-person (GTP or G2P) systems being one of the most common. Other AS/RS technologies include high-bay load, mini-load, shuttle-based, cube-based, and vertical lift modules (VLM).

Benefits and Applications of AS/RS:

The benefits of AS/RS technology are substantial and multifaceted:

- Space Optimization: AS/RS enables warehouses to operate around the clock with increased storage capacity within the same footprint by utilizing vertical space and compact layouts. This enables businesses to store more inventory without needing to expand their facilities.

- Inventory Accuracy: AS/RS systems virtually eliminate human error in storage and retrieval. These systems can increase operations by 50% with 99.9% accuracy, drastically reducing the costs associated with inventory discrepancies, lost items, and stock adjustments (MHI 2023 Annual Industry Report).

- Labor Efficiency: By automating the movement of goods into and out of storage, AS/RS significantly reduces the labor required for these tasks. A properly implemented system can operate 24/7 with minimal human intervention, requiring only minimal staff, maintenance personnel, and exception handlers, rather than a full staff or temporary workers.

- Enhanced Throughput: Modern AS/RS can achieve remarkably high throughput rates. Advanced systems with multiple load-handling devices can perform several hundred storage and retrieval operations per hour, enabling rapid response to order demand spikes.

- Safety Improvements: AS/RS minimize the need for human workers to operate in high-bay environments or use equipment like forklifts, which are a leading cause of warehouse injuries according to the National Safety Council (MSC). Reducing human exposure to height and heavy machinery dramatically improves workplace safety, decreasing nonfatal and fatal injuries.

Robotic Picking and Palletizing

The automation of picking and palletizing represents one of the most significant developments in warehouse technology, addressing tasks that have traditionally been among the most labor-intensive and challenging to automate.

Current Capabilities and Limitations

- Item Recognition: Modern picking robots identify thousands of different items using computer vision, 3D sensing, and machine learning (ML).

- Handling Versatility: Today’s robotic grippers incorporate various systems, including vacuum systems for flat surfaces, adaptive mechanical grippers for irregular shapes, soft grippers for delicate items, and hybrid systems.

- Speed and Throughput: Robotic picking systems can maintain a higher throughput compared to human workers, operating continuously across multiple shifts. However, performance varies based on product characteristics.

- Flexibility vs. Specialization: A fundamental trade-off exists where specialized robots achieve remarkable throughput on a narrow range of items, while more flexible systems handle greater variety at lower speeds, requiring alignment with a specific product mix.

Automated Sortation Systems

Automated sortation systems use robotics and/or conveyors to sort inventory based on pre-determined criteria, such as order, location, or size. Inventory is placed in these systems through conveyors, manual scanning, or robotic arms, and then sorted to various locations using robotics or additional conveyors.

Applications and Workflow Integration:

- Zone Routing: Conveyor systems with smart routing capabilities direct items through various warehouse zones based on processing requirements. This workflow optimization ensures products follow the most efficient path from receiving to shipping.

- Batch Processing: Modern sortation systems can group orders into batches for more efficient picking, then re-sort individual items into their respective orders. This approach significantly increases picking efficiency while maintaining order accuracy.

- Cross-Docking: High-speed conveyor and sortation systems enable efficient cross-docking operations, where incoming shipments are quickly processed and redirected to outbound shipping lanes with minimal storage time, reducing handling costs and accelerating throughput.

- Workstation Feeding: Intelligent conveyor systems can buffer and release items to workstations at the optimal pace, ensuring operators have a consistent flow of work without overwhelming them, maximizing both equipment and labor utilization.

- Returns Processing: Specialized sortation configurations can rapidly classify returned items by disposition category (restock, refurbish, discard), dramatically accelerating the returns handling process in e-commerce operations.

Autonomous Mobile Robots (ARMS) and Automated Guided Vehicles (AGVS)

Autonomous mobile robots (AMRs) can independently navigate warehouse floors to assist with tasks such as inventory retrieval and sorting. Automated guided vehicles (AGVs) are similar to AMRs but navigate along a fixed path or within an enclosed system.

Conveyors

Conveyors, which serve as fixed paths for moving items between different operational areas, remain critical components in high-volume operations. Conveyors can connect automation systems to other key warehouse systems or connect automation systems, such as an AS/RS, which feeds inventory to an automated sorter.

Warehouse Management Systems (WMS) and Automation Software

Autonomous mobile robots (AMRs) can independently navigate warehouse floors to assist with tasks such as inventory retrieval and sorting. Automated guided vehicles (AGVs) are similar to AMRs but navigate along a fixed path or within an enclosed system.

Role of WMS in Automated Environments

- Orchestration and Coordination: The WMS acts as the central orchestrator, directing robots, conveyors, AS/RS, and human workers while optimizing task sequences and resource allocation.

- Real-Time Visibility: Advanced WMS platforms provide immediate visibility into all warehouse activities and inventory status, enabling responsive operations and proactive issue resolution.

- Exception Management: Modern WMS platforms detect anomalies, route exceptions to appropriate handlers, and maintain operational flow despite disruptions that inevitably occur in automated systems.

- Resource Optimization: WMS systems continuously optimize equipment, space, inventory, and labor utilization through sophisticated algorithms that allocate tasks to robots and assign storage locations.

- Automated Decision-Making: Advanced WMS platforms autonomously make thousands of operational decisions based on rules and real-time conditions, escalating only those situations that truly require human judgment.

AI and Machine Learning Applications

Artificial intelligence (AI) and machine learning (ML) represent the most transformative technologies enhancing warehouse management systems today. As of 2025, 28% of companies report AI as being currently in use while 54% report AI adoption within five years (MHI 2025 Annual Industry Report).

Powerful AI and ML tools enable WMS platforms to move beyond rule-based optimization to truly intelligent operations that learn, adapt, and improve over time. By analyzing massive datasets from daily operations, AI-driven systems can identify patterns invisible to human operators, predict future events with remarkable accuracy, and make increasingly sophisticated decisions autonomously.

- Predictive Analytics: AI-enhanced WMS platforms analyze historical data to predict future events such as demand spikes, potential equipment failures, or inventory shortages, enabling proactive rather than reactive management.

- Intelligent Slotting: Machine learning algorithms continuously optimize inventory placement based on order patterns, product affinities, velocity changes, and seasonal trends, ensuring the most efficient warehouse layout at all times.

- Dynamic Task Allocation: AI systems assign tasks to robots, automation systems, and human workers based on complex models that account for current location, capabilities, workload, priority, and predicted future needs, maximizing overall throughput.

- Anomaly Detection: Machine learning models monitor thousands of operational parameters to detect subtle patterns that indicate potential issues before they cause disruptions, enabling preventive maintenance and process adjustments.

- Process Mining and Optimization: Advanced AI techniques analyze workflow data to identify bottlenecks, inefficiencies, and opportunities for improvement that may not be apparent through traditional analysis, driving continuous operational enhancements.

Major Types of Warehouse Automation Systems

Chapter 3

Implementation Strategies and Roadmap

Successfully implementing warehouse automation is as much about strategy and process as technology. Even the most advanced automation solutions will fail to deliver the expected results without a thoughtful, structured approach to implementation. This chapter provides a comprehensive framework for developing and executing an automation strategy that aligns with your organization’s needs, enhances efficiency, and increases the likelihood of a long-term ROI.

Assessing Your Warehouse Operations' Readiness for Automation

Before diving into automation technologies, evaluating your current operations is essential to determine your readiness for automation and identify the most promising opportunities.

Process Mapping and Analysis

Begin by documenting your current warehouse processes. Create visual process maps that capture each step from receiving to shipping, including decision points, handoffs, and exceptions. This exercise often reveals inefficiencies, redundancies, and bottlenecks that can be addressed with automation.

Data Collection and Analysis

Gather quantitative data on key operational metrics including order profiles, SKU characteristics, labor utilization, space usage, throughput, error rates, and seasonal patterns. Clear baseline metrics before automation enable proper before-and-after comparisons, which help accurately identify the ROI.

Pain Point Identification

Identify the most significant operational challenges, including labor-intensive processes, quality issues, capacity bottlenecks, physical strain concerns, repetitive tasks, and seasonal staffing. These pain points often represent the most promising opportunities for automation with the highest potential returns.

Future Requirements Planning

Look beyond current needs to anticipate future requirements such as projected growth, changing order profiles, new product lines, market shifts, and strategic initiatives. Planning for the future ensures investments remain relevant as the business evolves, protecting long-term ROI and preventing premature obsolescence.

Technical Infrastructure Evaluation

This evaluation examines your network infrastructure capacity, facility requirements, WMS functionality and integration capabilities, data standardization practices, IT support resources, and cybersecurity preparedness. Identifying technical limitations early allows for necessary upgrades or workarounds to be built into the implementation plan, preventing and mitigating challenges.

Creating a Phased Implementation Approach

Warehouse automation is most successful when implemented in a thoughtful, phased manner rather than attempting a “big bang” approach that introduces multiple technologies simultaneously.

The Case for Phased Implementation

- Risk Mitigation: Risk is mitigated by limiting the scope of each phase to manageable components, allowing for learning and adjustment between phases, minimizing operational disruptions, and enabling easier rollback if unexpected issues arise. Implementing automation incrementally enables organizations to identify and address challenges in controlled environments before they impact the entire operation, thereby dramatically improving the likelihood of overall project success.

- Financial Benefits: Phasing provides substantial financial advantages by spreading capital expenditures over multiple budget cycles, generating returns from early phases to help fund later phases, reducing financial risk through smaller incremental investments, and providing opportunities to adjust plans based on actual returns. This approach transforms a single large, high-risk investment into a series of smaller, more manageable investments with clear validation points, improving both cash flow management and overall ROI.

- Organizational Learning: Phasing creates a progressive learning curve where teams build expertise, confidence, and buy-in with simpler systems before tackling more complex ones. Lessons from initial phases guide future implementations, naturally developing skills and change management capabilities.

Timeline Considerations for Different Technologies

Different automation technologies have varying implementation timelines based on their complexity, infrastructure requirements, and operational impact. Understanding these timelines is crucial for realistic planning.

| Quick Implementation Technologies (3-6 Months) | |

|---|---|

| Mobile Computing and Scanning |

|

| Pick-to-Light/Put-to-Light Systems |

|

| Warehouse Execution Software |

|

| Medium Implementation Technologies (6-12 Months) | |

|---|---|

| Conveyor Systems |

|

| Voice-Directed Workflows |

|

| Semi-Automated Packing Solutions |

|

| Complex Implementation Technologies (12-24+ Months) | |

|---|---|

| Automated Storage and Retrieval Systems (AS/RS) |

|

| High-Speed Sortation |

|

| Robotic Picking Systems |

|

| Fully Integrated Automation Systems |

|

| Advanced AMR Implementations |

|

Chapter 4

Steps for a Successful Deployment

Successful automation deployment follows a structured methodology that addresses both technical and organizational aspects of implementation.

1. Planning and Design

Define Automation Requirements:

Develop measurable requirements for throughput rates, accuracy targets, flexibility needs, integration points, exception handling, and reporting needs.

Create a Conceptual Design:

Create a high-level design outlining key components, process flows, integration architecture, space allocation, and the overall operational concept.

Develop a Detailed Design:

Develop comprehensive documentation for equipment specifications, control systems, software workflows, integration interfaces, and physical layouts.

Validate Your Business Case:

Before implementation, review financial projections, confirm performance assumptions, verify ROI calculations, reconfirm strategic alignment, and ensure executive support.

2. Testing and Piloting

Test Proof of Concept:

Test critical components in controlled environments, validate integration points, confirm product handling capability, and identify challenges early.

Implement Controlled Piloting:

Implement automation in a limited area, maintain parallel conventional processes, train staff in real conditions, and document lessons learned.

3. Scaling and Optimization

Begin with a Phased Rollout:

Begin with lower-risk areas, build on successes, gradually increase scope, maintain fallback options, and adjust the timeline based on performance.

Adjust System Performance:

Collect system data, identify fine-tuning opportunities, implement regular optimization cycles, address gaps, and leverage vendor expertise.

Refine Processes:

Update operating procedures, streamline workflows, eliminate inefficient handoffs, improve exception handling, and optimize staff roles.

Chapter 5

Measuring Success in Warehouse Automation

Implementing warehouse automation represents a significant investment that requires comprehensive measurement to ensure expected returns. This chapter explores how to establish meaningful metrics and drive continuous improvement.

Key Performance Indicators (KPIs) for Automated Warehouses

Operational Performance Metrics

Measuring throughput is crucial for evaluating the performance of automation systems. Track orders processed per hour, lines picked, and units handled to establish baseline performance. It’s equally important to measure accuracy metrics and quantify inventory accuracy percentage and order error rates.

Cycle time metrics reveal process improvements throughout your operation. Measure order cycle time from receipt to shipment, put-away time, and pick-to-pack time, as these directly impact customer service. Additional metrics such as equipment usage and storage capacity can be tracked to identify optimization opportunities and maximize ROI.

Financial Performance Indicators

Cost metrics offer direct insight into the financial impact of automation. Monitor cost per order, labor cost percentage, and units processed per labor hour to quantify savings. Evaluate investment returns through capital return metrics and payback period tracking to justify expenditures and guide future decisions. Track inventory metrics, such as carrying costs and turns, to capture benefits beyond direct labor savings.

Customer Impact Metrics

Automation should ultimately improve customer service. Measure on-time delivery percentage, order cycle time from the customer perspective, and perfect order fulfillment rate. Assess flexibility through volume scalability range, new product introduction time, and peak season performance. Track quality factors including damage rates, returns due to warehouse error, and shipping quality.

Automation-Specific Metrics

Monitor technical performance through availability percentage, mean time between failures (MTBF), and mean time to repair (MTTR). Evaluate integration effectiveness with cross-system data accuracy, handoff success rate, and system synchronization metrics. Assess automation utilization, including robot utilization percentage, AS/RS storage utilization, and the active time of automated stations.

Real-World Results

Rocky Mountain ATV Reduces Manual Labor by 45% with an Automated Sorting System

To sustain same-day shipping amidst growing order volumes, Rocky Mountain ATV replaced its manual sorting operation with the OPEX® Sure Sort® system. This move reduced labor needs by 45%, cut walking time, and increased box packing from 26 to 40 per hour, with shipping accuracy reaching 99.97%. Sure Sort handles up to 2,400 units per hour with as few as five operators per shift. This allowed the team to scale effectively during peak seasons without compromising speed or accuracy.

Boux Avenue Enhances the Order Fulfillment Process, Reducing Temp Labor by 33%

UK lingerie and swimwear brand Boux Avenue turned to OPEX and implemented Sure Sort to reduce seasonal labor demands and increase operational efficiency. Before automation, the company relied on up to 250 additional temp workers during peak periods. Sure Sort enabled a 33% reduction in temporary staff and dramatically improved fulfillment speed, handling 95% of SKUs. Operators using the system can process 50 orders and 250 items per hour, five times more than previous methods.

Ingram Micro Implements OPEX Goods-to-Person Automation, Increasing Throughput

Ingram Micro, a global distributor serving over 161,000 customers, implemented two OPEX Perfect Pick® HD AS/RS systems at its Fort Worth, TX facility to address fulfillment challenges during peak seasons. The Perfect Pick HD systems improved throughput, reduced manual labor, and enhanced accuracy. Each system holds approximately 7,000 SKUs and uses 36 iBOTs for rapid tote delivery.

Conclusion

Moving Forward

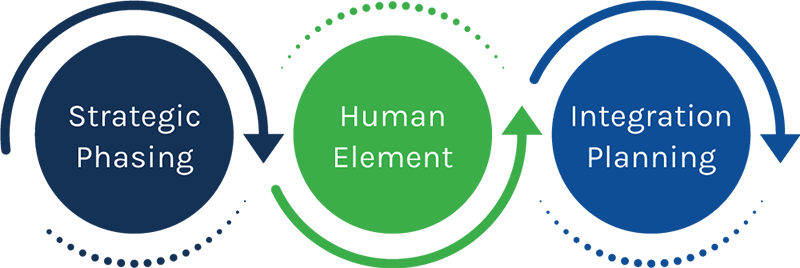

Throughout this guide, we’ve explored warehouse automation from key trends and foundational technologies to implementation strategies and operational impacts.

Key Takeaways

Strategic Phasing Delivers Better Results

Organizations that implement automation in thoughtful phases—building foundations first, capturing quick wins, and then advancing to more complex technologies—can achieve a higher ROI and encounter fewer implementation challenges.

The Human Element Remains Critical

Despite advances in automation technology, the human element remains essential. Successful organizations focus on elevating human roles rather than simply eliminating them, creating more engaging work while improving operational performance.

Integration is Often the Greatest Challenge

Technical integration, which involves connecting automated systems with existing technologies and processes, often presents the most significant implementation hurdle. Organizations that prioritize integration planning from the start can avoid costly delays and performance issues.

Begin your automation journey by defining clear business objectives rather than chasing technology for its own sake. What specific pain points are you trying to solve? What measurable outcomes would signal success? Take the time to thoroughly assess your current operations and plan your approach before selecting any specific technology.

The most successful organizations cultivate a culture where continuous improvement becomes second nature, where teams continually seek opportunities to optimize. Find the sweet spot between standardized solutions that reduce complexity and targeted customizations that deliver unique value for your specific operation.

Remember, warehouse automation isn’t the destination – it’s a powerful vehicle for business transformation. The leaders in this space aren’t just installing robots and software; they’re reimagining their entire operation, combining technological innovation with process excellence and workforce development. This holistic approach creates warehouse operations that not only keep pace with competitors but also establish sustainable advantages in an increasingly demanding business environment.

Ready to take the next step? Contact our team of experts to see how automation could make an impact on your operations.

Other Resources You Might Find Helpful

The True Cost of Paper: How Document Scanning Saves Your Business Money

The Real Money Saver: How Intelligent Hardware Empowers Cost-Effective Document Outsourcing

Cloud-Native Document Scanning: Unlocking Scalability and Accessibility for Your Digital Future

How to Integrate Document Scanners into Your Enterprise Without Adding IT Headaches

Is Your Business Future-Proof? Why Investing in Advanced Scanning Technology is Non-Negotiable

How Intelligent Scanning Cuts Costs and Drives ROI for BPOs

Seamless Integration and Future Ready Automation with AI

ZF Transforms Parts Kitting with the OPEX® Perfect Pick® HD, Putting the Brakes on its Manual Processes

Calculating Your ROI – Justifying Investment in Intelligent Document Scanners

The AI Advantage: Transforming Data Capture with Intelligent Document Processing (IDP)

NEXT LEVEL AUTOMATION

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.