Faster, Smarter, Efficient with Sure Sort

OPEX® Sure Sort® is the industry’s most versatile, scalable, configurable, and cost-effective automated sorting solution available anywhere. Sure Sort is engineered to help businesses of all sizes improve the overall efficiency of their distribution operations, save time and money, and meet the demands of a changing world.

Meet Sure Sort

Precision-Driven Tools for Optimal Operations

iBOT

The iBOT system can carry up to five pounds and is self-charging using ultra-capacitors, recharging while braking. It wirelessly communicates with traffic controllers to access all the sort destinations.

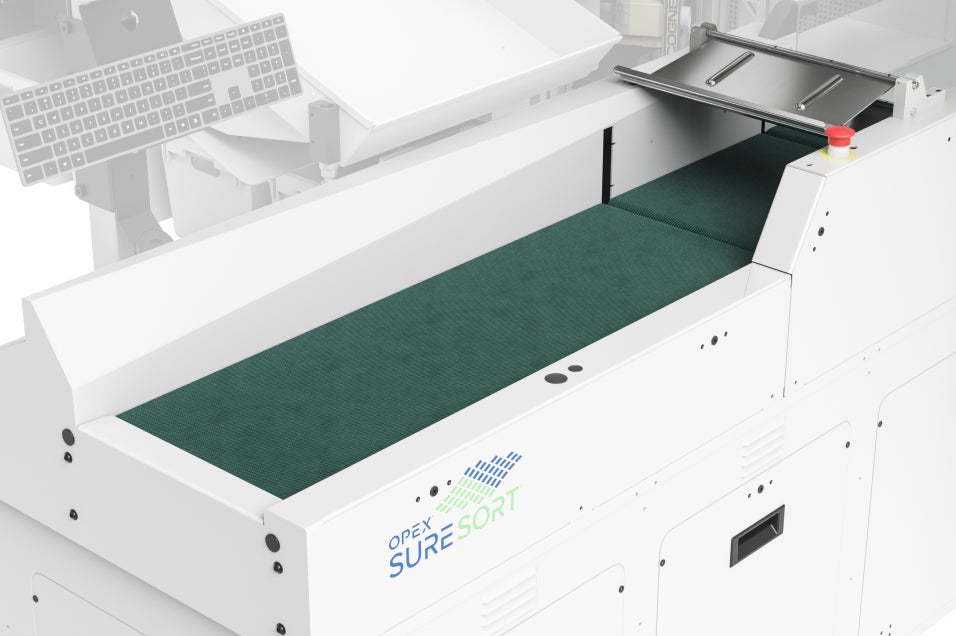

Induction Module

The Induction Module sets a maximum 6″ height for sorted items and monitors a 3″ gap between items. It uses image entry sensors to measure item length and can share conveyor state with upstream systems. It rejects items that don’t meet minimum gap requirements or exceed maximum length.

RFID Scan Tunnel

With six-sided scanning, the RFID Scan Tunnel reads up to eight barcodes per item and offers customizability for barcode scanning. It also reads RFID in items like tags, bags, and boxes. The Hand Scanner allows manual rescanning of items that aren’t easily read by the scan tunnel.

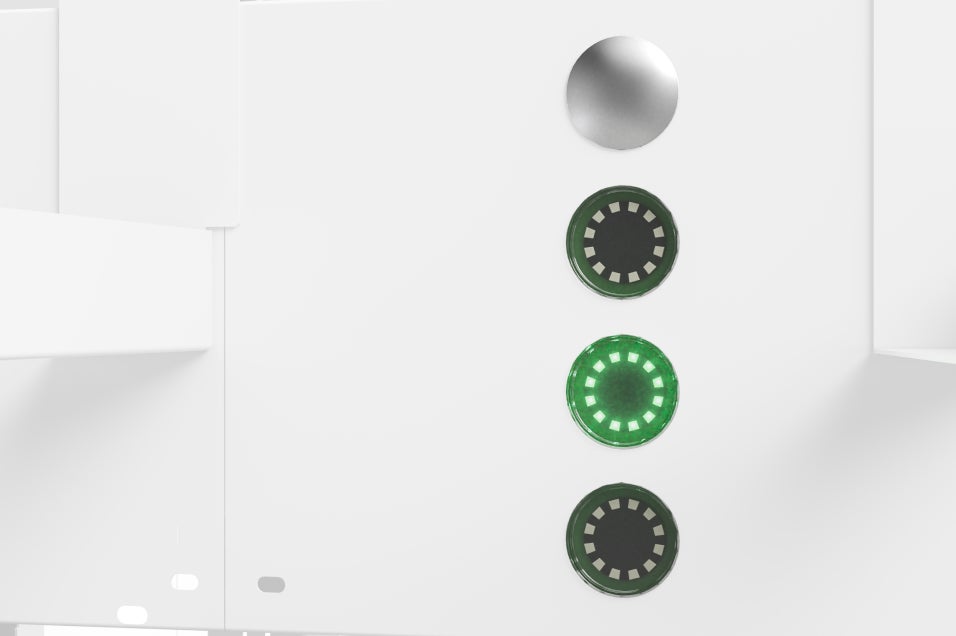

Pick-to-Light (PTL)

PTL systems use LED lights, including PTL strips and ring lights, with a wide range of colors. These lights indicate machine and bin status and are used by the warehouse control system (WCS) to instruct operators.

Sort Bin Configuration Expansion Modules

There can be a maximum of 11 expansion modules, each containing 6-8 columns. These modules are configurable to various bin types and allow for custom sort configurations based on defined parameters.

Sure Sort |

|

|---|---|

| Length | 1.55 m up to 13.96 m 1.13 m for each additional expansion module |

| Width | 3.35 m at the input conveyor 1.77 m at the expansion module |

| Height | 2.72 m |

| Product Length x Width Minimum | 5 cm x 5 cm or 25cm2 |

| Product Length x Width Maximum | 38.1 cm x 30.5 cm |

| Product Height | 0.017 cm to 15.24 cm |

| Product Weight | Up to 2.27 kg |

| iBOTs | Up to 22 |

| Delivery Bins/Totes/Boxes (Mixed & Various Sizes) | 7.62 cm, 10.16 cm, 15.24 cm, 27.94 cm, 35.56 cm Supports gaylord, EU tote (600x400x300 mm), and delivery chute |

| Throughput | Scalable up to 2,400 items per hour |

| Barcode Readers | Up to 6-sided, automated OPEX scan tunnel Fixed mount readers Hand scanner RFID Batch scan |

| Optional Dimensioner | Captures product dimension from 10 mm with a resolution of 2.5 mm Cubic volume bin reporting with dimensioner |

| Automated Return Conveyor | Items recalled by WMS are returned for secondary action |

| Pack-to-Light | Customizable LED indicators |

| Expansion Modules | Up to 11 |

| Induction Conveyor Location | Option to install on either the right or left side at the front of the system |

| Included Automation Interfaces | Ready to feed status, external e-stop, Machine Controls API, Order Creation Interface (S2O) |

Sure Sort |

|

|---|---|

| Length | 5.1 ft up to 45.8 ft 3.7 ft for each additional expansion module |

| Width | 11 ft at the input conveyor 5.8 ft at the expansion module |

| Height | 8.9 ft |

| Product Length x Width Minimum | 2 in x 2 in or 4 in2 |

| Product Length x Width Maximum | 15 in x 12 in |

| Product Height | 0.007 in to 6 in |

| Product Weight | Up to 5 lbs |

| iBOTs | Up to 22 |

| Delivery Bins/Totes/Boxes (Mixed & Various Sizes) | 3 in, 4 in, 6 in, 11 in, 14 in supports gaylord and delivery chute |

| Throughput | Scalable up to 2,400 items per hour |

| Barcode Readers | Up to 6-sided, automated OPEX scan tunnel Fixed mount readers Hand scanner RFID Batch scan |

| Optional Dimensioner | Captures product dimension from 0.4 in with a resolution of 0.1 in Cubic volume bin reporting with dimensioner |

| Automated Return Conveyor | Items recalled by WMS are returned for secondary action |

| Pack-to-Light | Customizable LED indicators |

| Expansion Modules | Up to 11 |

| Induction Conveyor Location | Option to install on either the right or left side at the front of the system |

| Included Automation Interfaces | Ready to feed status, external e-stop, Machine Controls API, Order Creation Interface (S2O) |

| HMI Languages Supported | English, French, German, Italian, Japanese, Korean, Polish, Portuguese, Spanish |

Find Out How Sure Sort Can Improve Your Operations.

“*” indicates required fields

Streamlining Operations, One Sort at a Time

Integrating Sure Sort® transforms your warehouse into a hub of precision and efficiency—experience streamlined operations, faster order fulfillment, and a system that grows with your business needs.

Streamlined

Keep Your Workflow Moving Downstream

- Process a vast number of items rapidly using minimal operators

- Ensures that warehouse operations are smooth and efficient.

- Fewer bottlenecks, faster order fulfillment, and a more streamlined supply chain

Cost-Effective

Fast ROI in Under Two Years

- Reduce manual labor needs and save on labor costs

- Repurpose labor for more essential tasks

- Low power consumption and efficient design translate to significant cost savings

Scalable

Adapt Without the Need for a Complete Overhaul

- Expansion modules make adjusting to growth in demand simple and easy to implement. Scales up to a maximum of 11 expansion modules

- Sort bin locations can be configured with mixed and various bin sizes and types.

- As volume grows, more iBOTs can be added to increase throughput to a max of 2400 UPH

Accurate

Improves Customer Satisfaction

- Comprehensive scanning capabilities and the pack-to-light system ensure that errors are minimized.

- Reduces costs associated with returns or misplaced items.

Versatile

Multifunctional Asset in Any Warehouse

- Whether it’s order fulfillment, reverse logistics, or in-store fulfillment, Sure Sort can handle a range of tasks efficiently.

- Eliminates the need for multiple systems to do different tasks, simplifying operations and training.

“The adaptiveness of the machine to give us a final solution and reduce labour is PHENOMENAL.”

Tom Sinclair

Executive Director at Kookaburra

Discover How Sure Sort® Has Impacted Other Operations

Case Study

Rocky Mountain ATV Integrates the OPEX® Sure Sort® System Into Its Distribution Center, Reducing Manual Labor By 45%

Case Study

Bleckmann Adopts Groundbreaking RFID Scan Tunnel For Sure Sort® Sorter, Achieving A 2X Increase In Operational Efficiency

White Paper

Increasing Distribution Center Productivity with Automated Put Walls

Insight

10 Ways to Lower Returns Costs and Optimize Your Reverse Logistics

NEXT LEVEL AUTOMATION

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.