Warehouse Automation

Tote I/O Automation

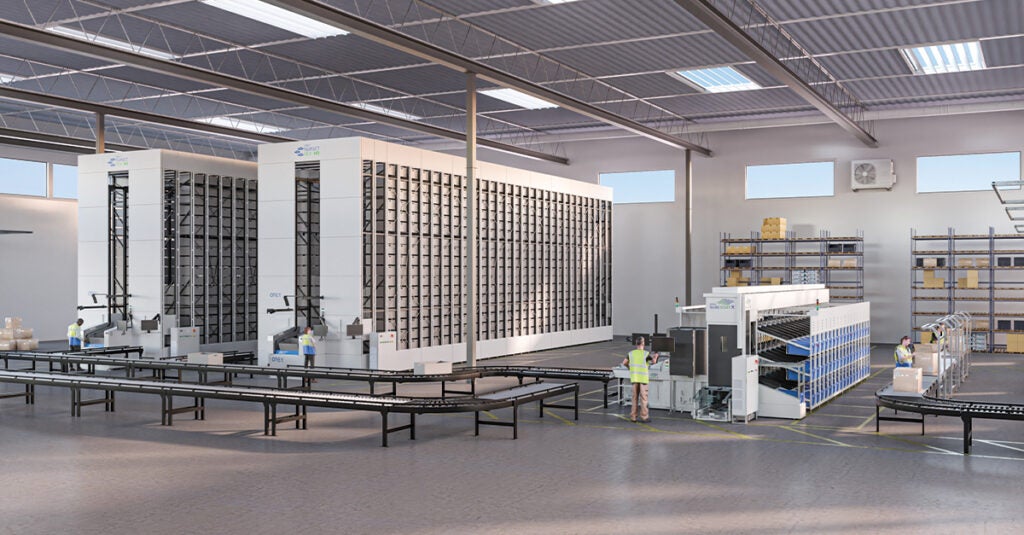

Implementing efficient automation systems is crucial for managing successful distribution centers. With labor shortages and increasing throughput demands, many operations teams seek reliable automated solutions for tote handling and storage.

OPEX® provides automated tote input and output (I/O) systems that use iBOT®s to place and retrieve totes from shelf locations. With 50 years in business, OPEX delivers proven warehouse automation systems that optimize processes and maximize available space.

Challenges That Benefit From a Tote Handling System

Many warehouses face the problem of needing to store several SKUs or bulky items in limited storage space. Manual tote handling systems are often inadequate at satisfying challenges involving:

- Tall, heavy, or unbalanced loads by weight or size.

- Facility structure features limit storage possibilities.

- Quality assurance and control for products or materials.

- Specific product handling requirements.

- Operator safety and ergonomics.

- Limited floorspace.

- Variable, nonstandard pallet sizes.

- Consistent, specific throughput needs.

Automated tote handling systems are designed to address these complex challenges and can be tailored to specific operational requirements.

The Value of Tote Automation for Distribution Centers

Operations professionals designing or redesigning distribution centers need to implement the right automation system, as proven automation capabilities are essential for long-term success. Tote automation solutions like tote-to-person automation bring totes to warehouse pickers automatically using an autonomous mobile robot like iBOTs. This system allows operators to focus on critical tasks without leaving their pick stations. Tote automation also plays a role in distribution center design, allowing operations professionals to use vertical storage to optimize floor space.

Advantages of Warehouse Tote Automation for Your Operations

Tote handling conveyor and picking systems for retail, logistics, or warehousing operations offer numerous benefits. Integrating these systems into your operations can:

Eliminate Pick Stations

Automation for totes streamlines operations at the aisle level. The I/O system retrieving and returning totes reduces dependency on human pick stations and the errors that accompany manual, human-reliant operations.

Scale Systems

Optimize High-Density Storage

Gain Installation Flexibility

Adapt the Design

Tote conveyors have front- and side-entry options with clearly defined structural modification guidelines.

Increase Throughput

Automation reduces the need for manual labor, improving efficiency in the tote transfer process. Automation makes cycle times more consistent, resulting in faster order fulfillment.

Improve Facility Utilization

Some storage environments, like cold rooms, are unsuitable for human workers. Placing automation totes in these areas maximizes your warehouse footprint.

Enhance Operational Flexibility

Automated totes are modular and integration-driven. As your business scales, the system can scale with you and be configured to meet throughput and facility-specific needs.

Reduce Labor Dependency

With tote-to-person automation eliminating the need for human-operated pick stations, you can decrease your dependency on labor. Fewer workers automatically reduce labor costs, increasing the return on investment.

Integrate with Warehouse Control Software (WCS)

Systems like Perfect Pick Tote I/O from OPEX seamlessly integrate with WCS through API and 3D visual support.

Discover OPEX’s Range of Tote I/O Automation Solutions

Perfect Pick Tote I/O: OPEX Tote-to-Person Automation

The Perfect Pick® Tote I/O system our solution for warehouse tote automation. This system improves the input and output of your totes,

using conveyance systems and iBOTs to automate the process. This tote I/O system supports efficiency and higher throughput, and totes of virtually any size, with key features like:

Automated Feeding and Retrieval

The Perfect Pick I/O system allows totes to be fed and retrieved automatically, relying on external conveyance systems and iBOT automation.

Increased Throughput

With optimal configuration for your tote-to-person automation system, you can increase your dual storage and retrieval cycles per hour while reducing the time spent on tote transfer.

Conveyance Integration

This tote handling system allows for third-party conveyance and hardware integration.

Flexible Installation Configurations

Our tote input/output system can be tailored to your needs. The Perfect Pick Tote I/O can support:

- One input and one output conveyor per aisle.

- Conveyors at the front, rear, right, or left of the aisle.

- Entry points at various heights.

Sure Sort X® with Xtract® Tote IO Modules

The Sure Sort® X with Xtract Tote IO Module enhances sortation efficiency by seamlessly moving totes into and out of the system. Using retrieval iBOTs, totes can be automatically routed to a pack station for direct transfer into a customer’s end tote or shipping box,

ready for downstream palletization.

Automated Tote Retrieval

iBOTs unload totes directly from the system to streamline sortation

Barcode Tracking

A barcode scanner integrated into the input section ensures each tote is identified and tracked for accuracy.

Pack Station Integration

Totes can be delivered in the locked closed position, ensuring secure transfer to the customer’s tote or shipping box for immediate palletization

Enhanced Efficiency

By removing manual handling steps, the Tote IO Module minimizes touchpoints, reduces errors, and accelerates throughput.

Infinity® Tote IO Automation

Infinity’s tote handling system leverages iBOT technology to automate the storage, retrieval, and transfer of totes across its high-density racking structure. This enables scalable, flexible, and space-efficient tote-to-person operations.

Dynamic Tote Handling

iBOTs autonomously place and retrieve totes from shelf locations, maximizing storage density and accessibility.

Scalable Design

Infinity Tote IO adapts as operations grow, supporting expanded throughput and evolving warehouse layouts.

Flexible Layouts

Tote IO modules can be configured at the front, rear, or sides of the system to fit existing facility constraints

System Integration

Compatible with OPEX control software and APIs, Infinity Tote IO connects seamlessly with WMS/WCS platforms.

High-Density Storage

Designed to accommodate a large number of SKUs in a minimal footprint while maintaining speed and accuracy.

Perfect Pick® Tote I/O: OPEX® Tote-to-Person Automation

The Perfect Pick® Tote I/O system our solution for warehouse tote automation. This system improves the input and output of your totes, using conveyance systems and iBOTs to automate the process. This tote I/O system supports efficiency and higher throughput, and totes of virtually any size, with key features like:

Automated Feeding and Retrieval

The Perfect Pick I/O system allows totes to be fed and retrieved automatically, relying on external conveyance systems and iBOT automation.

Conveyance Integration

This tote handling system allows for third-party conveyance and hardware integration.

Increased Throughput

With optimal configuration for your tote-to-person automation system, you can increase your dual storage and retrieval cycles per hour while reducing the time spent on tote transfer.

Flexible Installation Configurations

Our tote input/output system can be tailored to your needs. The Perfect Pick Tote I/O can support:

- One input and one output conveyor per aisle.

- Conveyors at the front, rear, right, or left of the aisle.

- Entry points at various heights.

Perfect Pick® Tote I/O: OPEX® Tote-to-Person Automation

The Perfect Pick® Tote I/O system our solution for warehouse tote automation. This system improves the input and output of your totes, using conveyance systems and iBOTs to automate the process. This tote I/O system supports efficiency and higher throughput, and totes of virtually any size, with key features like:

Automated Feeding and Retrieval

The Perfect Pick I/O system allows totes to be fed and retrieved automatically, relying on external conveyance systems and iBOT automation.

Conveyance Integration

This tote handling system allows for third-party conveyance and hardware integration.

Increased Throughput

With optimal configuration for your tote-to-person automation system, you can increase your dual storage and retrieval cycles per hour while reducing the time spent on tote transfer.

Flexible Installation Configurations

Our tote input/output system can be tailored to your needs. The Perfect Pick Tote I/O can support:

- One input and one output conveyor per aisle.

- Conveyors at the front, rear, right, or left of the aisle.

- Entry points at various heights.

Perfect Pick® Tote I/O: OPEX® Tote-to-Person Automation

The Perfect Pick® Tote I/O system our solution for warehouse tote automation. This system improves the input and output of your totes, using conveyance systems and iBOTs to automate the process. This tote I/O system supports efficiency and higher throughput, and totes of virtually any size, with key features like:

Automated Feeding and Retrieval

The Perfect Pick I/O system allows totes to be fed and retrieved automatically, relying on external conveyance systems and iBOT automation.

Conveyance Integration

This tote handling system allows for third-party conveyance and hardware integration.

Increased Throughput

With optimal configuration for your tote-to-person automation system, you can increase your dual storage and retrieval cycles per hour while reducing the time spent on tote transfer.

Flexible Installation Configurations

Our tote input/output system can be tailored to your needs. The Perfect Pick Tote I/O can support:

- One input and one output conveyor per aisle.

- Conveyors at the front, rear, right, or left of the aisle.

- Entry points at various heights.

Perfect Pick® Tote I/O: OPEX® Tote-to-Person Automation

The Perfect Pick® Tote I/O system our solution for warehouse tote automation. This system improves the input and output of your totes, using conveyance systems and iBOTs to automate the process. This tote I/O system supports efficiency and higher throughput, and totes of virtually any size, with key features like:

Automated Feeding and Retrieval

The Perfect Pick I/O system allows totes to be fed and retrieved automatically, relying on external conveyance systems and iBOT automation.

Conveyance Integration

This tote handling system allows for third-party conveyance and hardware integration.

Increased Throughput

With optimal configuration for your tote-to-person automation system, you can increase your dual storage and retrieval cycles per hour while reducing the time spent on tote transfer.

Flexible Installation Configurations

Our tote input/output system can be tailored to your needs. The Perfect Pick Tote I/O can support:

- One input and one output conveyor per aisle.

- Conveyors at the front, rear, right, or left of the aisle.

- Entry points at various heights.

Perfect Pick® Tote I/O: OPEX® Tote-to-Person Automation

The Perfect Pick® Tote I/O system our solution for warehouse tote automation. This system improves the input and output of your totes, using conveyance systems and iBOTs to automate the process. This tote I/O system supports efficiency and higher throughput, and totes of virtually any size, with key features like:

Automated Feeding and Retrieval

The Perfect Pick I/O system allows totes to be fed and retrieved automatically, relying on external conveyance systems and iBOT automation.

Conveyance Integration

This tote handling system allows for third-party conveyance and hardware integration.

Increased Throughput

With optimal configuration for your tote-to-person automation system, you can increase your dual storage and retrieval cycles per hour while reducing the time spent on tote transfer.

Flexible Installation Configurations

Our tote input/output system can be tailored to your needs. The Perfect Pick Tote I/O can support:

- One input and one output conveyor per aisle.

- Conveyors at the front, rear, right, or left of the aisle.

- Entry points at various heights.

Perfect Pick® Tote I/O: OPEX® Tote-to-Person Automation

The Perfect Pick® Tote I/O system our solution for warehouse tote automation. This system improves the input and output of your totes, using conveyance systems and iBOTs to automate the process. This tote I/O system supports efficiency and higher throughput, and totes of virtually any size, with key features like:

Automated Feeding and Retrieval

The Perfect Pick I/O system allows totes to be fed and retrieved automatically, relying on external conveyance systems and iBOT automation.

Conveyance Integration

This tote handling system allows for third-party conveyance and hardware integration.

Increased Throughput

With optimal configuration for your tote-to-person automation system, you can increase your dual storage and retrieval cycles per hour while reducing the time spent on tote transfer.

Flexible Installation Configurations

Our tote input/output system can be tailored to your needs. The Perfect Pick Tote I/O can support:

- One input and one output conveyor per aisle.

- Conveyors at the front, rear, right, or left of the aisle.

- Entry points at various heights.

How to Prepare for Tote Automation

Operations managers can prepare their distribution center for automation by completing the following steps:

Assess the Current Process

Evaluate your current processes to assess their performance. Document these workflows to identify bottlenecks and measure current throughput. Distribution centers with high order volumes benefit from automation, and integrating tote automation in areas needing efficiency improvements encourages growth.

Evaluate the Space

Consider your warehouse space to determine whether it can accommodate tote automation systems, including conveyors and automated robots. The system may have vertical clearance requirements, so you may need to adjust your warehouse layout to accommodate it. Many automated tote systems have configuration options to integrate with existing systems.

Plan Implementation

To implement the system, you can launch the entire system at once or use a phased rollout to gradually introduce the system for minimal disruptions. Your team will need to be trained on the automation system, so establish training requirements or create a program to ensure a successful implementation.

Why Choose OPEX for Your Automated Tote System?

OPEX is a trusted leader in warehouse automation solutions for tote I/O and beyond. When you choose us as your supplier of tote handling systems, your business can take advantage of:

Lifelong Support

OPEX is your partner for life. At every stage of your system’s life cycle, you can rely on our experts for planning, repairs, and ongoing support.

24/7 Support

We provide around-the-clock support to our customers worldwide. Our service agreements cover parts and labor, so you can get professional support whenever needed.

Skilled Technicians

Our staff are highly skilled, boasting an average of 10 years of experience. Our technicians undergo routine, comprehensive training to ensure success in implementing and maintaining your automated tote systems.

Configurable Systems

OPEX® tote automation solutions are highly configurable, accommodating numerous tote sizes, storage spaces, and operational needs.

NEXT LEVEL AUTOMATION

Learn How Tote Input and Output Systems Can Enhance Your Business

Contact our team to schedule a consultation with our warehouse automation experts. We will assess your current operational needs and demonstrate how our automated tote systems can support your distribution center goals.