Maximum throughput.

Minimal intervention.

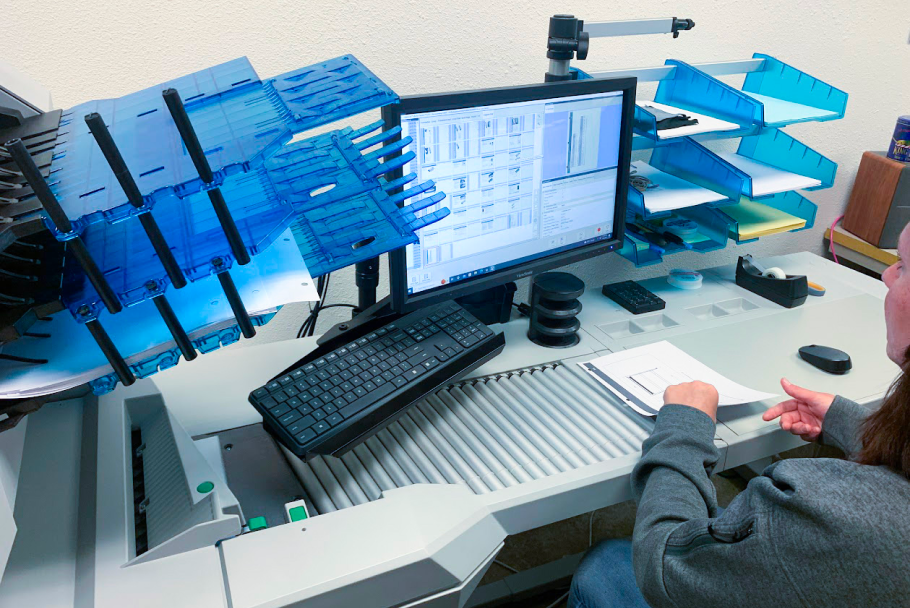

Production Power Without the Production Size

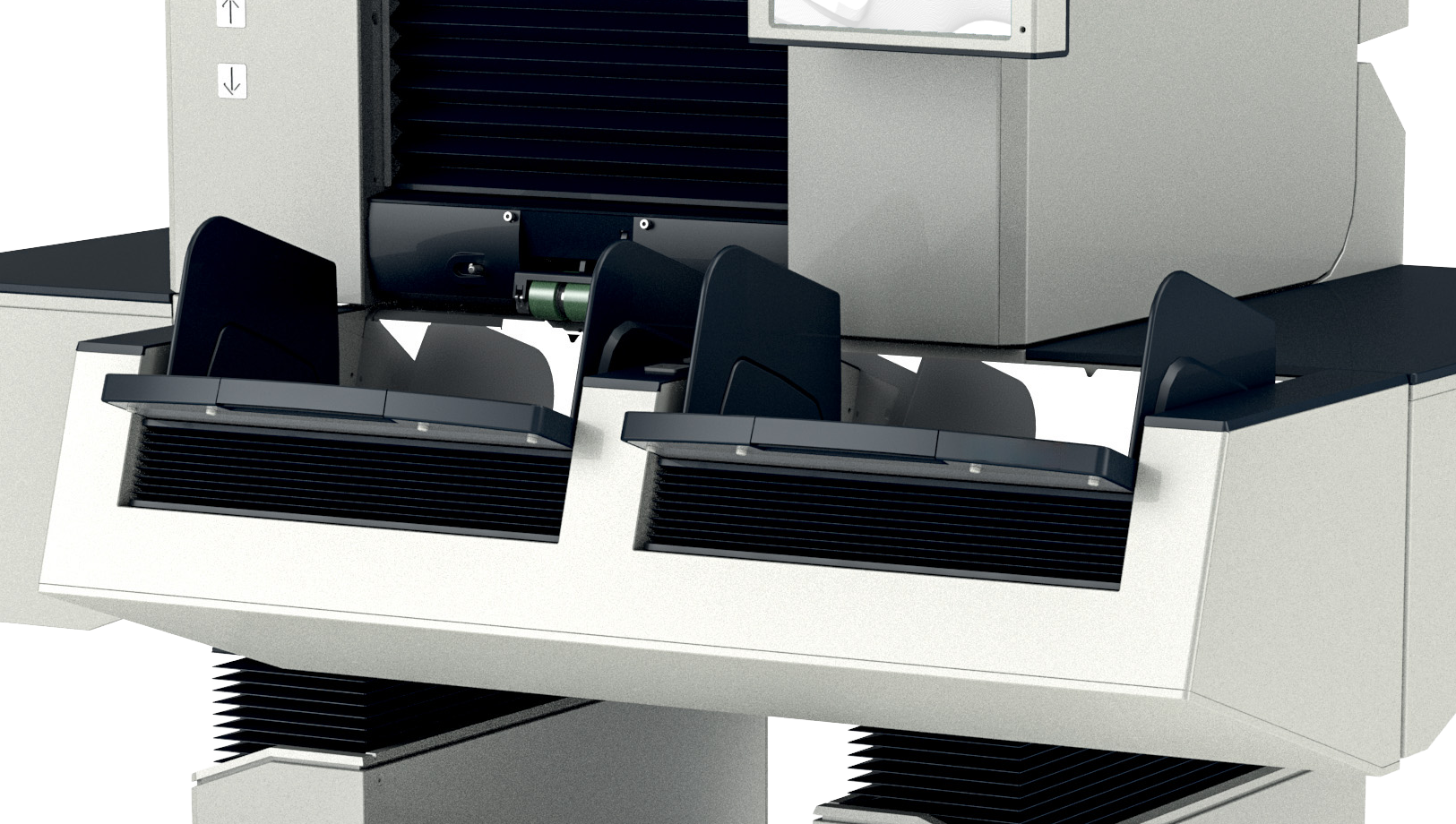

The Velo 8000 Series is engineered for organizations that demand nonstop, high-volume enterprise production scanning. Designed for 24/7, multi-shift operation, the 8000 Series combines dual high-capacity feeders, automated output handling, active sorting, versatile media handling, and advanced onboard image processing to keep work moving without pauses or workarounds.

Powered by InoTec technology, Velo 8000 delivers sustained throughput, precise document handling, and high-quality, compliance-ready images with archival capability for large-scale digitization projects. It’s purpose-built for service bureaus, government agencies, and enterprise capture operations where uptime, accuracy, and predictability are non-negotiable.

VELO 8000

Run Longer. Worry Less.

The Velo 8000 Series delivers industry-leading performance for the most demanding production environments. Configured with dual 1,000-sheet feeders, automatic tray switching, and an unlimited duty cycle, the 8000 Series is built to scan continuously—without stopping to reload paper or reset jobs.

A height-adjustable ergonomic stand, a large 9” color touchscreen, and motorized full-path access reduce operator strain and speed recovery when intervention is required. Combined with gentle belt transport, no-scratch Gorilla Glass™ optics, and multi-sensor feed protection, Velo 8000 maintains consistent image quality and document safety at extreme throughput—shift after shift.

Equipped with a large 7” color touchscreen, gentle belt transport, no-scratch Gorilla Glass™, and an integrated rear straight-through exit tray, the Velo 3120 minimizes operator intervention while protecting fragile and mixed documents. It’s a smart choice for mid-volume digitization where quality, uptime, ease of operation, and cost control matter most.

Dual Input System

Dual 1,000-sheet feeders automatically switch during operation, allowing operators to load paper while the scanner runs. This enables truly continuous, scanning and eliminates stop-and-reload interruptions during long production jobs.

Height-Adjustable Stand

A motorized, height-adjustable stand lets operators set a comfortable working height for seated or standing operation. This reduces fatigue during long shifts, improves ergonomics, and helps maintain consistent productivity across operators.

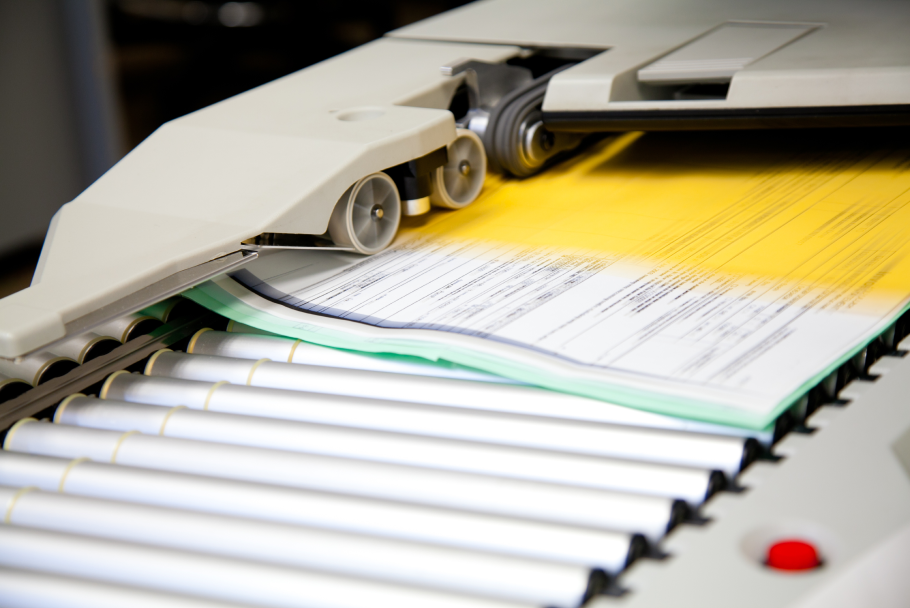

Straight-Through Paper Path

A rear straight-paper exit allows fragile, thick, or inflexible documents to pass through without tight turns. This minimizes stress on originals and supports active sorting, exception handling, or document separation at full production speed.

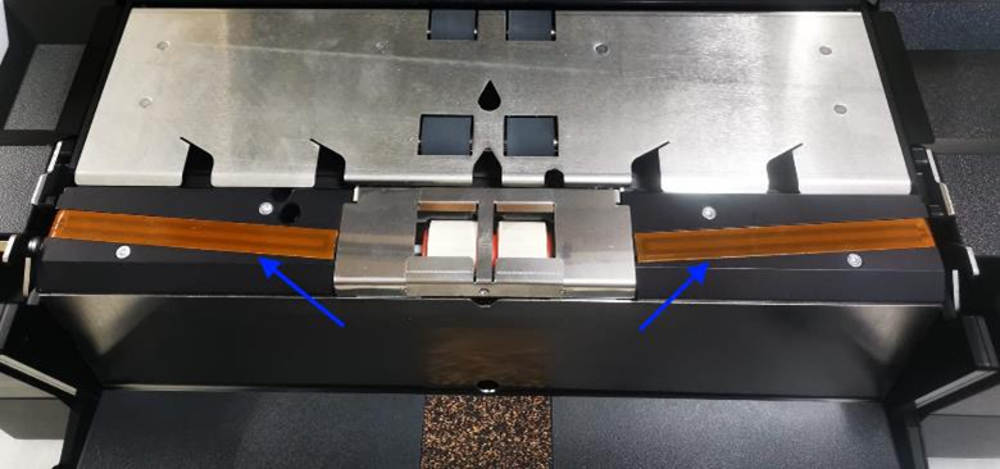

No-Scratch Gorilla Glass™

Hardened, scratch-resistant scan glass protects against abrasion caused by staples, paper clips, and debris that degrade image quality over time. Combined with high-quality CCD sensors, the no-scratch glass delivers consistent, edge-to-edge image clarity and lowers long-term maintenance costs.

Multi-Sensor Feed Protection

Ultrasonic and metal detection sensors work together to identify double-feeds, overlaps, and hazards before they enter the scan path. Feed protection events are logged to support exception handling and audit requirements without stopping production.

Large Capacitive Touchscreen

A 9” color touchscreen provides clear job status, counters, alerts, and guided recovery instructions. Traffic-light logic and intuitive controls reduce training time and make complex production workflows easier to manage.

Find Out How Velo Can Improve Your Operations

“*” indicates required fields

Production-Class Scanning That Keeps Work Moving

Velo 8000 Series scanners are built to eliminate bottlenecks in enterprise capture environments. By combining continuous-duty hardware, multi-sensor feed protection, and high-quality image output with archival capability, Velo delivers faster throughput, lower risk, and predictable results—shift after shift.

Durable

Built for Continuous Production

Engineered for multi-shift, unattended operation with an unlimited duty cycle, the Velo 8000 keeps scanning at full speed without slowing or stopping—so large jobs stay on schedule.

Continuous Feeding

Uninterrupted Paper Feeding

Dual high-capacity input feeders automatically switch during operation, allowing operators to load paper while the scanner runs and eliminating downtime caused by reloads.

Document Protection

Built-In Feed Protection & Detection

Multi-sensor detection identifies double-feeds, overlaps, and metal before documents enter the scan path, reducing rescans, data loss, and workflow disruptions.

Ergonomic

Operator-First Design

A height-adjustable stand, large touchscreen interface, and motorized full-path access reduce fatigue and speed recovery, keeping operators productive throughout long shifts.

Integrated

Seamless System Connectivity

TWAIN/ISIS compatibility and optional Velo Scan+ software enable predictable integration with capture, ECM, and archival systems for confident, audit-ready delivery.

What makes the Velo 8000 Series different from other high-volume production scanners?

The Velo 8000 Series is engineered for unattended, multi-shift production, not just high speed. Dual high-capacity feeders and output trays, automated output handling, and continuous-duty components allow Velo to run for hours without intervention. Combined with gentle document handling and onboard image processing, Velo 8000 delivers predictable throughput, lower risk, and consistent results at scale.

Discover How Velo Has Impacted Other Operations

The Importance of Data Security in Automated Document Management for Banks

Palm Beach County Tax Office

Automating Donation Processing for Nonprofits

Same-Day Delivery: Making It a Reality With Automated Sorting Systems

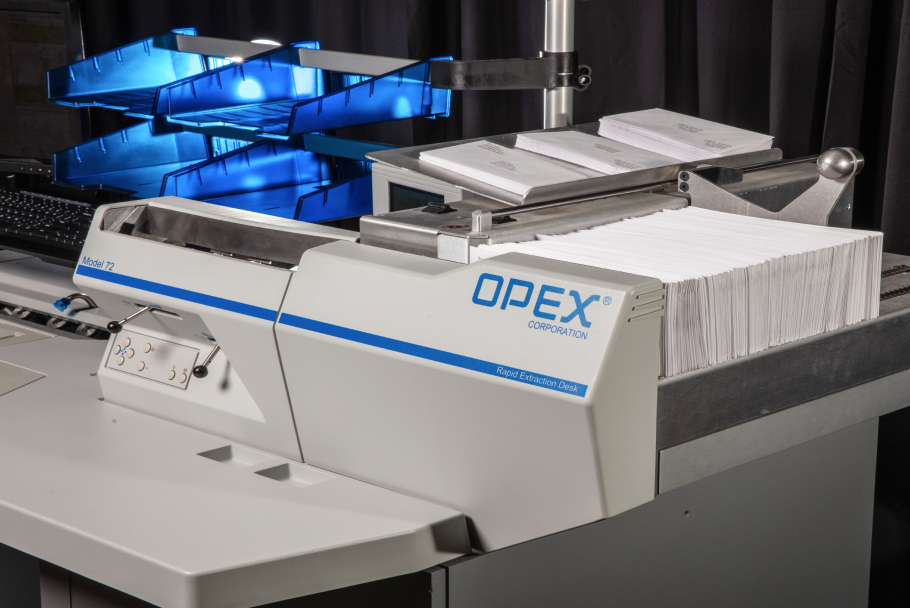

RMMI Streamlines Scanning Efficiency with OPEX® Falcon®+ One-Touch Scanners

Optimizing Your Warehouse Layout for Automation

Reducing Errors and Improving Accuracy With Automated Sorting in Logistics

Automating Invoice Processing for Energy Companies

Streamlining Operations: The Impact of Automation on Financial Institutions

Boosting E-Commerce Efficiency: The Role of Warehouse Automation

Next Level Automation

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.