Perfect Pick®

Warehousing Elevated

Automated Storage and Retrieval System (AS/RS)

Find Out How Perfect Pick Can Improve Your Operations

Adaptable, Efficient, Secure Goods-to-Person Order Fulfillment

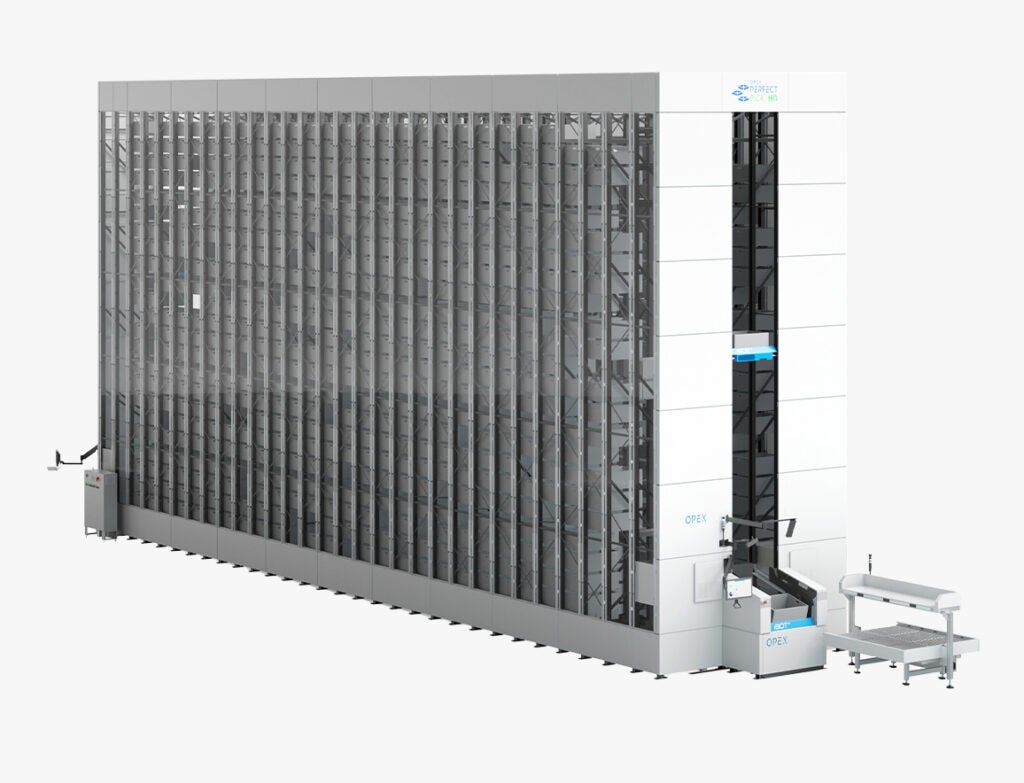

Engineered for high-density storage without compromising efficiency, Perfect Pick® is an automated storage and retrieval system that uses iBOT® wireless robots to deliver inventory directly to operators.

Meet Perfect Pick

Simplify Order Fulfillment Automation

Designed for today’s challenges and ready for tomorrow’s opportunities, Perfect Pick meets your unique business needs. Make the most of your unused vertical warehouse space with a fully configurable dense storage solution. With space savings of 8:1, Perfect Pick keeps up with supply chain disruptions and constantly changing customer demands by offering more storage for inventory, all within your current footprint.

Our Testimonials

Perfect Pick Success Stories

"We selected Perfect Pick for multiple reasons, but the most important reason was scalability."

“The perfect pick system is part of the whole idea of this campus – to provide efficiency and enhanced customer service to our customers.”

“The Perfect Pick HD system has been received well by our employees. They are excited about the system and see the advantages it provides.”

Chuck Cornell

GM and Senior Operations Manager, Newegg

Bill Kullback

CFO, BioLegend

Casey Harrison

Director of Operations, Ingram Micro

Our AS/RS Systems

A Hub of Precision and Efficiency

Perfect Pick’s major components work together, providing a solution that makes the most of your space while enhancing efficiency.

iBOT®

Perfect Pick iBOTs are wireless and self-charging robotic vehicles that navigate the system to find, retrieve, and deliver totes to an operator working at a pick station. Each iBOT holds up to 80 lbs.

Totes

Totes securely store your items in the Perfect Pick system. They are available in different sizes to adapt to your inventory. Each tote can be subdivided or designed to hold cartons and boxes for flexible storage. Totes can be switched out for trays to hold your container while remaining easily accessible by iBOTs.

Structure/Rack

Each Perfect Pick aisle contains racking that holds totes, allowing iBOTs to travel in the system and retrieve inventory. Build as high as 32’ and 200’ long to maximize the unused vertical space in your warehouse and reduce your footprint.

Cortex Equipment Control System (ECS)

The brains of the operation, the Cortex Equipment Control System (ECS), guides item picking and replenishment to the system while tracking inventory levels. Perfect Pick’s API will also integrate with virtually any WCS system.

Present Station

Operators don’t need to search an entire warehouse to search for items. When working at a present station, iBOTs deliver inventory directly to the operator. Each Perfect Pick aisle can have up to two stations, one at each end.

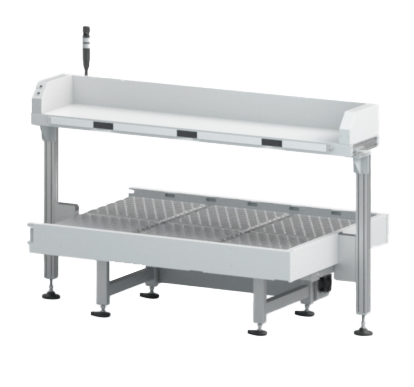

Workstation (optional)

The automated workstation keeps cartons moving toward the system on a conveyor for streamlined picking and replenishment with the push of a button.

NEXT LEVEL AUTOMATION

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.