Overcoming Common Challenges in Warehouse Automation

A guide to managing major challenges with warehouse operations and automation projects.

13 min read

60-Second Summary

In today’s competitive logistics landscape, warehouse automation offers transformative benefits, but not without significant challenges. This comprehensive guide tackles the most pressing obstacles faced by warehouse operations leaders: persistent bottlenecks that drain efficiency, workforce resistance to technological change, integration nightmares with legacy systems, daunting upfront costs, data security vulnerabilities, and supply chain disruptions. Whether you’re just beginning your automation journey or looking to enhance existing systems, this ebook equips you with practical insights to navigate complexities, maximize ROI, and future-proof your warehouse operations for sustainable competitive advantage.

Introduction

Warehouse automation has significantly transformed supply chain operations, enhancing efficiency, reducing costs, and improving accuracy. Adopting automation technologies represents a significant shift for businesses, offering transformative benefits across inventory management, order fulfillment, and shipping processes. However, as with any large-scale innovation, implementing automation is not without its challenges. Companies must navigate technical, operational, and human factors to ensure successful integration.

This guide explores the most common challenges faced during warehouse automation projects and provides actionable solutions designed to help organizations overcome these hurdles. Whether it’s addressing workforce adaptation, ensuring system compatibility, or balancing costs with expected returns, this comprehensive resource aims to equip decision-makers with the insights needed to maximize the potential of automation. By tackling these challenges head-on, businesses can position themselves as leaders in an increasingly competitive and tech-driven industry.

Chapter 1

Addressing Bottlenecks in Warehouse Operations

Understanding the Challenge

Warehouse bottlenecks are a significant obstacle to efficient operations. These inefficiencies often stem from manual processes, outdated equipment, and poorly optimized workflows. Inventory management delays, for example, contribute to discrepancies and overstocking. A report by Zebra Technologies found that 62% of warehouses experience inefficiencies due to outdated inventory tracking systems. Similarly, order picking remains a costly challenge, accounting for up to 50% of warehouse operating costs, according to the 2022 WERC Benchmarking Study. Shipping and receiving inefficiencies further exacerbate bottlenecks, leading to delays and customer dissatisfaction.

Solutions

Optimize Warehouse Space

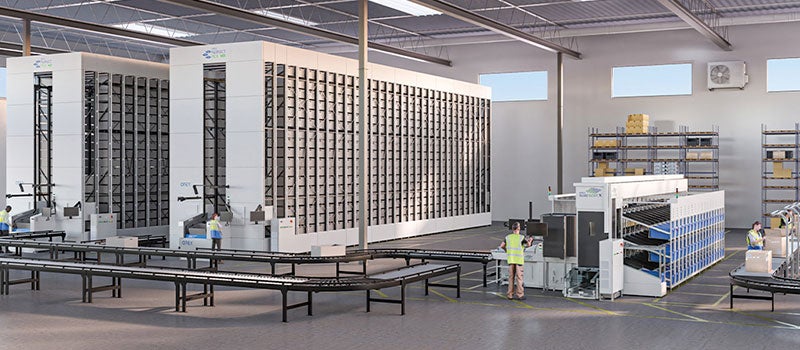

To mitigate bottlenecks, warehouses can optimize layouts by reorganizing storage areas, reducing travel distances, and zoning dedicated areas for fast-moving, slow-moving, and seasonal items. Automation tools such as conveyor belts, automated storage and retrieval systems (AS/RS), and dynamic shelving can increase space utilization by 85% while improving picking accuracy to 99.9%, according to Modern Materials Handling.

Enhance Efficiency with New Tools

A warehouse management system (WMS) enhances operational efficiency by offering real-time visibility into inventory levels, optimizing order prioritization, and reducing order errors by 30%, as found by Deloitte. Automated sorting systems, automated guided vehicles (AGVs), and robotics also facilitate material handling, allowing scalability during peak seasons. Research by MarketsandMarkets projects the global AGV market will grow from $2 billion in 2022 to $4.5 billion by 2027.

Data-driven workflow analysis further enhances efficiency. Utilizing analytics to track order cycle time, pick accuracy, and shipping delays allows continuous operational refinement. Real-time performance monitoring ensures that warehouses meet the high demands of modern supply chains.

Chapter 2

Managing Workforce Adaptation and Resistance

Understanding the Challenge

Workforce resistance is a common challenge as automation becomes more prevalent. Many employees fear job displacement or struggle to adapt to new technologies. A study by McKinsey & Company reports that nearly 60% of warehouse employees worry about the impact of automation on job security. Additionally, gaps in technical knowledge can slow implementation, creating further resistance to change.

Solutions

Investing in Training Programs

To address these concerns, businesses should invest in training and development programs. Providing hands-on workshops, e-learning modules, and upskilling opportunities helps employees transition smoothly into new roles. Ensuring job retention through reskilling initiatives can further alleviate concerns.

Use a Phased Implementation Approach

A phased implementation approach allows employees to adapt to automation gradually. According to Harvard Business Review, organizations that engage employees in technological transitions report a 40% higher success rate in adoption.

Communicate the Benefits and Rewards Clearly

Clear communication of automation benefits, such as improved workplace safety and reduced manual labor, fosters a positive shift in workplace culture. Recognizing and rewarding employees who embrace automation encourages a supportive environment.

Automation also presents new career opportunities. Employees can transition into roles focused on system maintenance, robotics oversight, and data analysis. Businesses can foster a more engaged workforce by reframing automation as a tool for efficiency rather than a threat to employment.

Chapter 3

Overcoming Integration Issues with Legacy Systems

Understanding the Challenge

Many warehouses operate on outdated systems that do not seamlessly integrate with modern automation solutions. According to Gartner, 54% of warehouse managers cite system incompatibility as a primary reason for delayed automation adoption.

Solutions

Employ API and Cloud-Based Solutions

API-based solutions help bridge the gap between legacy systems and modern automation tools, enabling real-time data synchronization. Cloud-based warehouse management systems (WMS) enhance scalability and security, improving operational efficiency by 32%, according to PwC.

Transition Gradually

Gradual system overhauls minimize disruptions. Prioritizing automation solutions with the highest immediate impact, such as automated sorting and barcode scanning, allows smoother transitions.

Implement a Unified Data Management Strategy

A unified data management strategy ensures consistency across warehouse functions. Investing in master data management (MDM) tools eliminates redundancies, enhances data accuracy, and improves visibility into inventory levels, order processing, and fulfillment efficiency.

Chapter 4

Balancing Automation Costs with ROI

Understanding the Challenge

The high upfront investment in warehouse automation is a major concern. However, according to McKinsey & Company, businesses implementing automation typically achieve payback within 18 to 36 months.

Solutions

A strong business case for automation should include labor savings, inventory accuracy improvements, and revenue growth. Research by PwC found that automation can reduce operational costs by 20% and improve efficiency by 25%.

Leasing and financing options, as well as government incentives such as those offered by the National Institute of Standards and Technology (NIST), can reduce the financial burden. Pilot programs help validate ROI before full-scale automation adoption.

By considering indirect benefits such as reduced employee turnover, lower injury rates, and improved customer satisfaction, businesses can enhance their financial justification for automation.

Chapter 5

Ensuring Data Security and Compliance

Understanding the Challenge

As warehouses adopt IoT (internet-of-things), AI, and cloud-based automation, cybersecurity threats become increasingly concerning. Automation introduces multiple points of vulnerability, as connected devices, real-time data tracking, and cloud storage create potential entry points for cyberattacks.

Additionally, regulatory compliance remains a key challenge for warehouse operations. Warehouses must adhere to industry standards such as OSHA (Occupational Safety and Health Administration) for worker safety, ISO 27001 for data security, and GDPR (General Data Protection Regulation) for handling customer information. Failure to comply with these regulations can lead to heavy fines, reputational damage, and operational disruptions. A study by IBM Security found that the average data breach cost in 2023 was $4.45 million, highlighting the financial risks associated with inadequate security measures.

Solutions

By implementing these cybersecurity and compliance strategies, warehouses can protect sensitive data, maintain regulatory compliance, and safeguard business operations. With increasing reliance on automation and interconnected systems, prioritizing security is no longer optional but necessary for long-term success.

Implement Multi-Layered Security Measures

To mitigate cybersecurity risks, warehouses should implement multi-layered security measures. Strong encryption protocols should be used for both stored and transmitted data, ensuring that sensitive business and customer information remains secure. Role-based access control (RBAC) can help restrict unauthorized access by ensuring only authorized personnel can interact with critical systems. Regular cybersecurity training for employees is essential, as human error accounts for nearly 88% of security breaches, according to a report by Verizon’s Data Breach Investigations.

Conduct Regular Security Audits and Penetration Tests

Conducting regular security audits and penetration testing helps identify vulnerabilities before they can be exploited. The National Institute of Standards and Technology (NIST) recommends routine security assessments to maintain compliance with evolving cybersecurity standards and regulations.

Utilize Automation Solutions Pre-Certified for Regulatory Standards

To enhance compliance, businesses should adopt automation solutions that are pre-certified for regulatory standards. Many warehouse management systems (WMS) and cloud providers offer compliance tools that ensure adherence to GDPR, ISO 27001, and OSHA requirements. For example, cloud-based WMS solutions with built-in compliance reporting can reduce the risk of regulatory violations and streamline audits.

Risk management should extend beyond internal security measures to include third-party vendors. Conducting due diligence on suppliers, logistics partners, and automation technology providers can help mitigate supply chain vulnerabilities. Implementing contractual agreements requiring vendors to meet cybersecurity and compliance standards minimizes external threats.

Develop a Comprehensive Incident Response Plan

Developing an incident response plan is critical for minimizing cyberattacks or compliance failure damage. A study by the Ponemon Institute found that businesses with a well-structured incident response plan reduce breach-related costs by an average of $2.66 million. Warehouses should establish protocols for rapid response, including isolating affected systems, notifying stakeholders, and documenting the breach to meet regulatory reporting requirements.

Chapter 6

Managing Supply Chain Disruptions with Automation

Understanding the Challenge

Supply chain disruptions have become a persistent challenge for warehouse operations, especially in the wake of global events such as the COVID-19 pandemic, geopolitical conflicts, and climate-related disasters. A study by McKinsey & Company found that 93% of supply chain leaders reported experiencing pandemic-related disruptions, with many struggling to recover due to inefficient forecasting and inventory management.

A major issue contributing to these disruptions is the lack of real-time visibility into inventory levels, transportation logistics, and supplier performance. Without automated tracking systems, warehouses struggle to respond proactively to delays, shortages, and shifts in consumer demand. According to a report by Gartner, only 21% of supply chain organizations have end-to-end visibility, which limits their ability to react swiftly to unexpected events.

Solutions

By integrating AI-driven forecasting, automated inventory management, diversified supplier networks, and resilient logistics solutions, warehouses can significantly enhance their ability to withstand supply chain disruptions.

Utilize AI-Driven Demand Forecasting for Proactive Adjustments

To mitigate supply chain disruptions, businesses must leverage AI-driven demand forecasting. Predictive analytics allows warehouses to anticipate supply fluctuations and adjust inventory levels proactively. A study by Deloitte found that companies using AI-based forecasting tools reduced inventory holding costs by 20% and improved order accuracy by 30%.

Implement Automated Inventory Management

Automated inventory management is another critical solution for improving supply chain resilience. Implementing RFID and IoT-enabled tracking systems provides real-time visibility into inventory movements, enabling warehouses to detect potential stockouts or overstocking issues before they become critical.

Conclusion

Future-Proofing Warehouse Operations

Warehouse automation is no longer a luxury; it is necessary for businesses looking to remain competitive in an increasingly complex and fast-paced supply chain environment. Companies that strategically implement automation across inventory management, logistics, and fulfillment processes can achieve significant efficiency gains while minimizing operational risks.

Invest in scalable, flexible automation solutions

A crucial aspect of future-proofing warehouse operations is investing in scalable and flexible automation solutions. Businesses should focus on adopting technologies that can grow with their needs, such as AI-powered forecasting, robotics, and cloud-based WMS platforms. According to PwC, companies that integrate predictive analytics into their supply chain operations see a 20% improvement in efficiency and a 15% reduction in costs.

Empower Employees with Training and Engagement

Employee empowerment is equally critical to ensuring a smooth transition to automation. Investing in upskilling programs, engaging workers in the implementation process, and fostering a culture of continuous learning will help mitigate resistance to change and ensure seamless integration of automated solutions.

Prioritize Data-Driven Decision-Making

Data-driven decision-making will remain at the heart of automation success. Businesses that leverage real-time data and analytics will have a competitive edge in optimizing warehouse performance, improving order accuracy, and responding proactively to supply chain disruptions.

Focus on Long-Term Resilience and Customer-Centric Operations

Ultimately, warehouse automation is not just about adopting new technology. It is about creating smarter, more resilient, and more customer-centric operations. By taking a strategic and holistic approach to automation, businesses can secure long-term success in an ever-evolving market landscape.

Other Resources You Might Find Helpful

NEXT LEVEL AUTOMATION

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.