Integrating AS/RS with Other Automation Technologies

Best practices for integrating AS/RS with other automation systems

10 min read

60-Second Summary

Automated Storage and Retrieval Systems (AS/RS) are transforming warehousing by maximizing space utilization, reducing labor costs, and boosting order accuracy. When integrated with technologies such as Warehouse Management Systems, Autonomous Mobile Robots, and robotic picking systems, they enable real-time tracking, predictive maintenance, and streamlined operations. Despite challenges like interoperability, high upfront costs, and cybersecurity risks, companies can overcome these obstacles with standardized protocols and comprehensive training. Ultimately, embracing AS/RS integration helps future-proof supply chains and secure a competitive edge in a complex logistics landscape.

Introduction

The modern warehouse is evolving rapidly, driven by increasing consumer demands, the rise of e-commerce, and the need for greater operational efficiency. To remain competitive, companies are turning to automation technologies to optimize storage, retrieval, and material handling processes. Among these technologies, Automated Storage and Retrieval Systems (AS/RS) have emerged as a critical component of warehouse automation, enabling businesses to improve space utilization, reduce labor dependency, and enhance order accuracy.

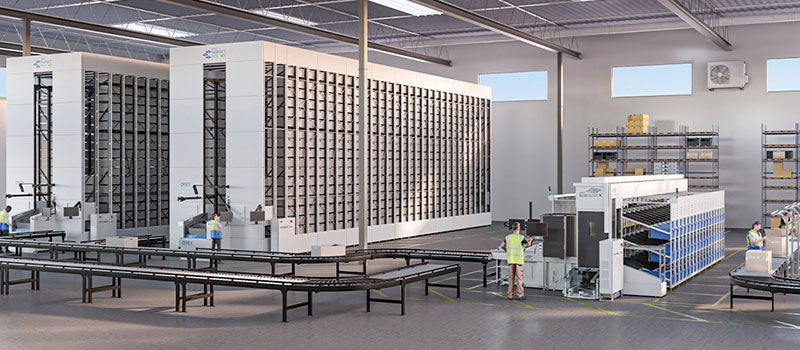

However, AS/RS does not operate in isolation. Its full potential is realized when integrated with complementary automation solutions, such as Warehouse Management Systems (WMS), Automated Sorting Systems, Autonomous Mobile Robots (AMRs), Automated Guided Vehicles (AGVs), and robotic picking systems. These integrations create a seamless flow of materials and information, enhancing overall warehouse efficiency and reducing operational bottlenecks.

According to the Material Handling Institute (MHI), AS/RS can increase storage density by up to 85% while reducing labor costs by 40%. These statistics underscore the transformative impact of AS/RS when combined with other automation technologies.

This eBook examines the advantages, obstacles, and best practices for integrating AS/RS with other automation systems. We will explore how different warehouse roles—ranging from operations managers to logistics directors and COOs—can leverage AS/RS integration to achieve strategic business objectives. By understanding the interaction between AS/RS and other automation technologies, businesses can drive efficiency, improve order fulfillment, and future-proof their supply chain operations.

AS/RS can increase storage density by up to 85% while reducing labor costs by 40%.

Chapter 1

Understanding AS/RS and Its Role in Automation

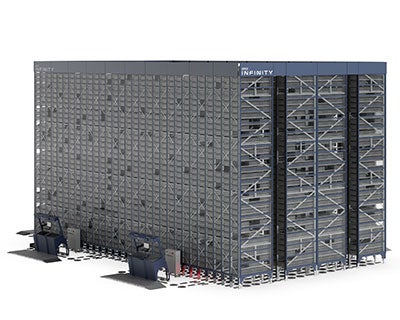

Automated Storage and Retrieval Systems (AS/RS) are a foundational component of warehouse automation, designed to store and retrieve materials with high precision and efficiency. These systems are typically composed of automated cranes, shuttle systems, or robotic arms that move inventory to and from designated storage locations with minimal human intervention. AS/RS solutions vary in complexity, ranging from simple vertical carousels to sophisticated multi-aisle robotic retrieval systems integrated with artificial intelligence (AI) and machine learning (ML) algorithms.

Key Benefits of AS/RS

- Enhanced Storage Capacity – Maximizes warehouse space efficiency by utilizing vertical storage and high-density shelving configurations. This allows companies to store more inventory within the same footprint, increasing capacity by up to 85%.

- Reduced Labor Dependency – Minimizes human intervention by automating storage and retrieval processes. This reduces labor costs by up to 40% and alleviates workforce shortages.

- Faster and More Accurate Order Fulfillment – Automates retrieval and picking processes, leading to improved speed and accuracy while reducing errors. Picking accuracy can reach 99.9%, minimizing mis-picks and returns.

- Improved Inventory Control – Provides real-time stock visibility and seamless integration with WMS, preventing overstocking and stockouts.

- Increased Safety and Reduced Workplace Accidents – Reduces physical strain on workers and minimizes risks associated with manual material handling, improving compliance with OSHA regulations.

Chapter 2

The Case for Integrating AS/RS with Other Technologies

AS/RS is most effective when integrated with complementary automation technologies. A Warehouse Management System (WMS) enables real-time inventory tracking and seamless communication with AS/RS, reducing discrepancies and optimizing order fulfillment (MHI).

The integration of Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) further streamlines the transportation of materials. Companies such as Amazon and DHL use AMRs to reduce bottlenecks and operational costs (DHL Logistics).

Robotic Picking Systems enhance warehouse efficiency by using AI-powered vision systems for precision picking and packing. Studies show that robotic picking can achieve 99.9% accuracy while increasing order processing speeds.

Conveyor and Sortation Systems integrate with AS/RS to automate product movement between storage and processing zones. Large-scale distribution centers rely on these systems to manage high-volume order fulfillment efficiently (Westfalia Technologies).

The Internet of Things (IoT) and AI Analytics further optimize AS/RS performance by providing real-time monitoring and predictive maintenance insights. Companies implementing IoT and AI in warehouse automation report improved efficiency and cost savings (McKinsey & Company).

Benefits of Integration

Integrating AS/RS with automation technologies results in faster order fulfillment, particularly in high-volume industries such as retail and e-commerce. Automated systems also contribute to lower operational costs, as companies experience reductions in labor and inventory errors, with some organizations seeing up to 40% cost savings.

Additionally, AS/RS integration enhances accuracy and quality control by reducing human errors in picking and sorting, ensuring precise order processing. This is critical for industries requiring high precision, such as pharmaceuticals and electronics. Finally, real-time data-driven decision-making improves inventory forecasting and operational efficiency (McKinsey & Company).

Chapter 3

Overcoming Integration Challenges

Common Challenges and Solutions

While AS/RS integration offers significant advantages, businesses must address challenges such as interoperability, high costs, workforce adaptation, cybersecurity, and system reliability.

1. Interoperability Issues

Warehouse automation systems often use different communication protocols, creating integration difficulties. Companies should adopt standardized communication protocols like OPC UA, MQTT, and RESTful APIs to enable seamless system integration. Middleware solutions can help synchronize data and optimize performance. Businesses implementing interoperability solutions report a 20% efficiency increase (McKinsey & Company).

2. High Capital Investment

The cost of AS/RS implementation can be significant, especially for small and mid-sized enterprises. A phased implementation strategy helps companies focus on high-impact areas first. Leasing and financing options can also offset initial costs. AS/RS can lead to 40% labor savings and 30% space optimization, making it a sound investment (MHI).

3. Workforce Training and Adaptation

Employees may resist automation due to job security concerns or lack of familiarity with the technology. Implementing comprehensive training programs through hands-on workshops and simulations can ease the transition. Businesses that prioritize training see 25% higher productivity (Deloitte).

4. Cybersecurity Risks

Interconnected AS/RS systems are vulnerable to cyber threats. Companies should use firewalls, encryption, and multi-factor authentication (MFA) to protect warehouse networks. Regular security audits help identify vulnerabilities. Proactive cybersecurity measures reduce breach-related costs by an average of $1.76 million per incident (IBM).

5. System Reliability and Downtime

Unexpected AS/RS failures can disrupt warehouse operations. Implementing predictive maintenance with IoT sensors and AI analytics helps detect issues early, reducing downtime. Companies using predictive maintenance report a 25-30% drop in maintenance costs and a 70% decrease in unexpected failures (PwC).

6. Scalability and Future-Proofing

AS/RS solutions must adapt to future growth. Choosing modular and scalable automation ensures flexibility. Cloud-based warehouse management systems also help businesses scale efficiently, reducing long-term upgrade costs.

Conclusion

The Future of AS/RS Integration

The integration of Automated Storage and Retrieval Systems (AS/RS) with other automation technologies is transforming the future of warehousing and logistics. Companies that embrace AS/RS integration are poised to experience greater operational efficiency, cost reduction, and improved order fulfillment accuracy. As supply chains become increasingly complex, the ability to leverage AS/RS alongside Warehouse Management Systems (WMS), Autonomous Mobile Robots (AMRs), robotic picking systems, and IoT-driven analytics will be a key differentiator in achieving long-term success.

The ongoing advancements in AI, machine learning, and cloud-based automation platforms will continue to enhance AS/RS functionality, making these systems more adaptive, scalable, and efficient. As predictive maintenance capabilities grow through IoT and AI analytics, warehouses will see fewer operational disruptions and lower maintenance costs. Additionally, the integration of real-time data-driven decision-making will allow businesses to optimize inventory levels, reduce waste, and improve responsiveness to market demands.

Investing in interoperability, workforce training, cybersecurity, and scalable automation solutions will ensure businesses remain competitive in an evolving logistics landscape. Organizations that proactively address integration challenges—such as interoperability issues, capital investment concerns, and workforce adaptation—will not only future-proof their operations but also gain a strategic advantage in the industry.

The future of AS/RS is not just about automation—it’s about creating intelligent, interconnected, and highly efficient warehouse ecosystems that can adapt to the ever-changing demands of global supply chains. Companies that take the lead in AS/RS integration today will be well-positioned to meet future challenges with agility, efficiency, and sustained growth. By addressing these challenges, businesses can unlock AS/RS’s full potential. Investing in interoperability, workforce training, cybersecurity, and scalable solutions ensures long-term success, improving warehouse efficiency and cost-effectiveness.

Are you ready to take your warehouse operations to the next level? Contact OPEX today and speak with a specialist that can assist in navigating the evolving landscape of data-driven decision-making.

Other Resources You Might Find Helpful

NEXT LEVEL AUTOMATION

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.