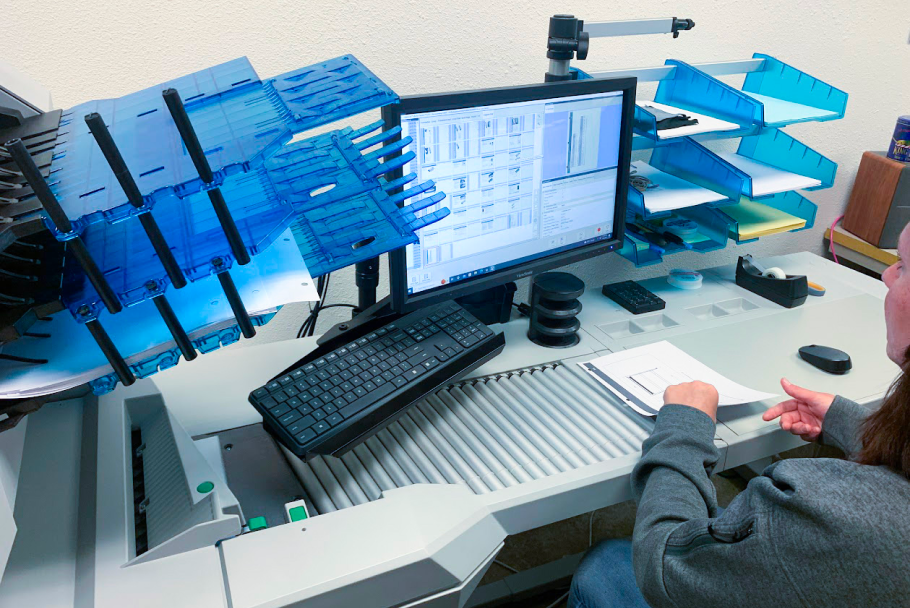

Desktop Production-Class Scanning.

Compact Footprint.

Production Power Without the Production Size

The Velo 3120 and Velo 6000 Series bring true desktop production scanning to a compact footprint. Powered by InoTec technology, Velo combines continuous-duty hardware, gentle document handling, and high-quality, compliance-ready imaging with archival capability—without sacrificing usability or reliability.

Designed for service bureaus, government agencies, healthcare providers, and enterprise capture operations, the Velo 3120 and 6000 Series deliver predictable performance and consistent image quality across high-volume digitization workflows. Whether scaling for backfile conversion or modernizing daily capture operations, Velo keeps work moving cleanly, safely, and at speed.

VELO 3120

Compact by Design. Built for Desktop Production.

Velo 3120 delivers production-class reliability in a compact desktop scanner built for continuous daily use. With a 120-ppm scan speed, unlimited duty cycle for daily production, and a 500-sheet feeder, it’s ideal for organizations that demand consistent throughput without stepping up to a larger production footprint.

Equipped with a large 7” color touchscreen, gentle belt transport, no-scratch Gorilla Glass™, and an integrated rear straight-through exit tray, the Velo 3120 minimizes operator intervention while protecting fragile and mixed documents. It’s a smart choice for mid-volume digitization where quality, uptime, ease of operation, and cost control matter most.

VELO 6000

Engineered for Endurance. Ready to Scale.

The Velo 6000 Series is engineered for high-throughput desktop production environments that can’t afford downtime. With models scaling up to 250 ppm, a 750-sheet feeder, and a continuous-duty design, the 6000 Series delivers sustained performance across long production days and demanding workloads.

Advanced media handling—including variable input pressure, optional slow down mode, and a metal rear straight-through exit—allows operators to process everything from fragile archival records to heavy stock with confidence. Optional upgrades, including speed and 4-tray sorting, let organizations expand capacity and functionality as volumes grow—without replacing hardware.

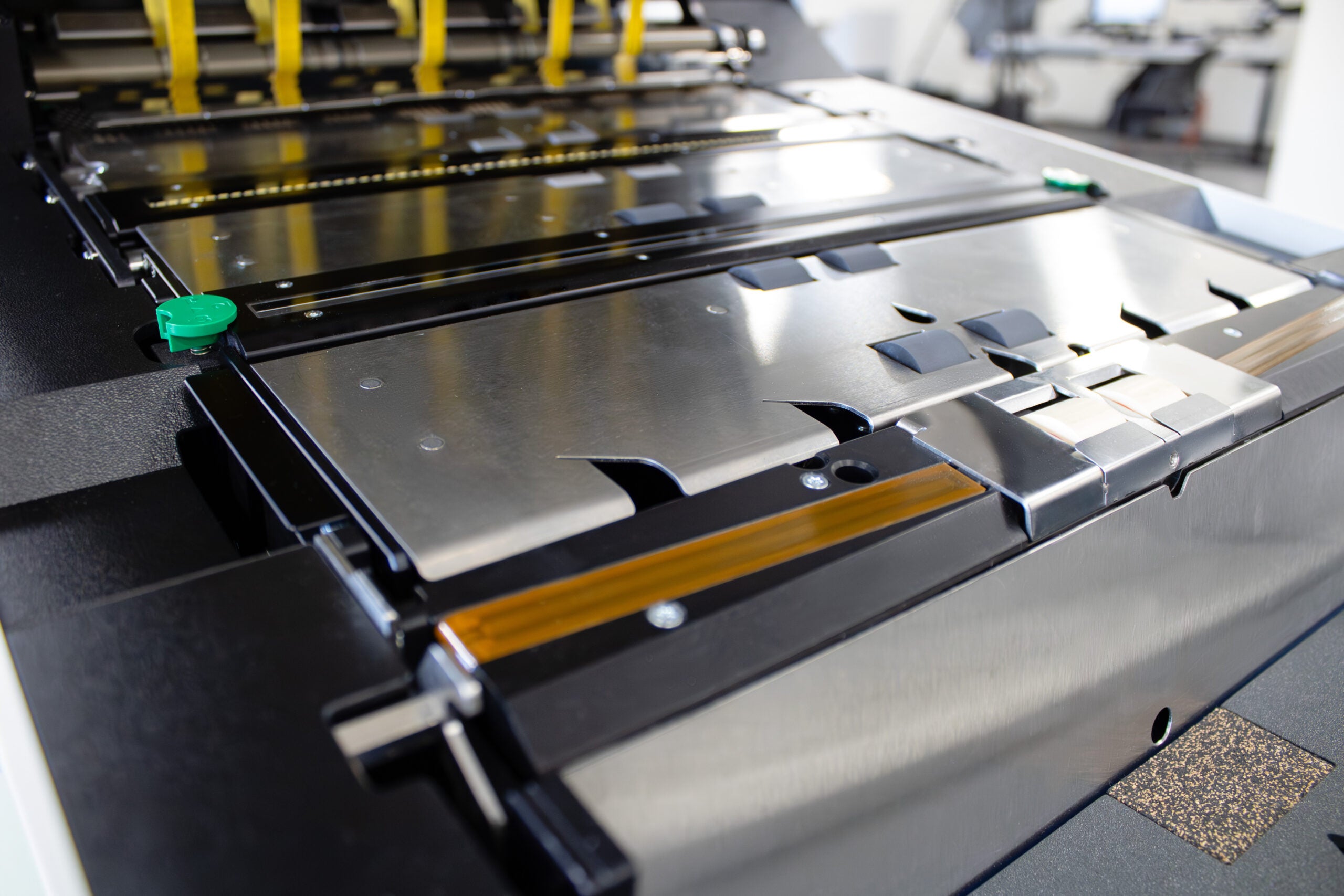

Variable-Input pressure switch

Automatically adjusts feed pressure to match document thickness and condition. Operators can confidently process fragile pages, curled paper, or heavy stock while reducing jams, misfeeds, and document damage—without slowing production.

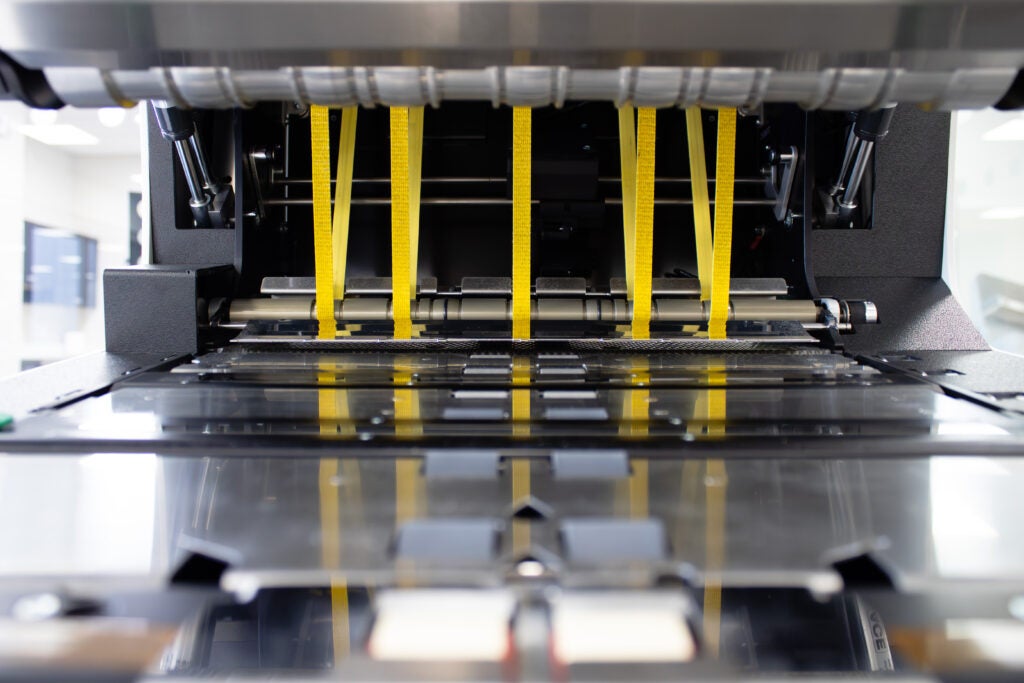

Gentle Belt Transport System

A low-impact belt-driven transport moves documents with controlled surface contact instead of aggressive rollers. This design protects the paper, including fragile and mixed media, improves feed reliability, and maintains consistent image alignment at full scan speeds, without routine belt maintenance.

Multi-Sensor Feed Protection

Multiple independently controlled ultrasonic sensors detect double-feeds, overlaps, and hidden inserts before they cause downstream issues. Sensor logic can be tuned per job. Helping operators maintain throughput while preventing data loss and rescans.

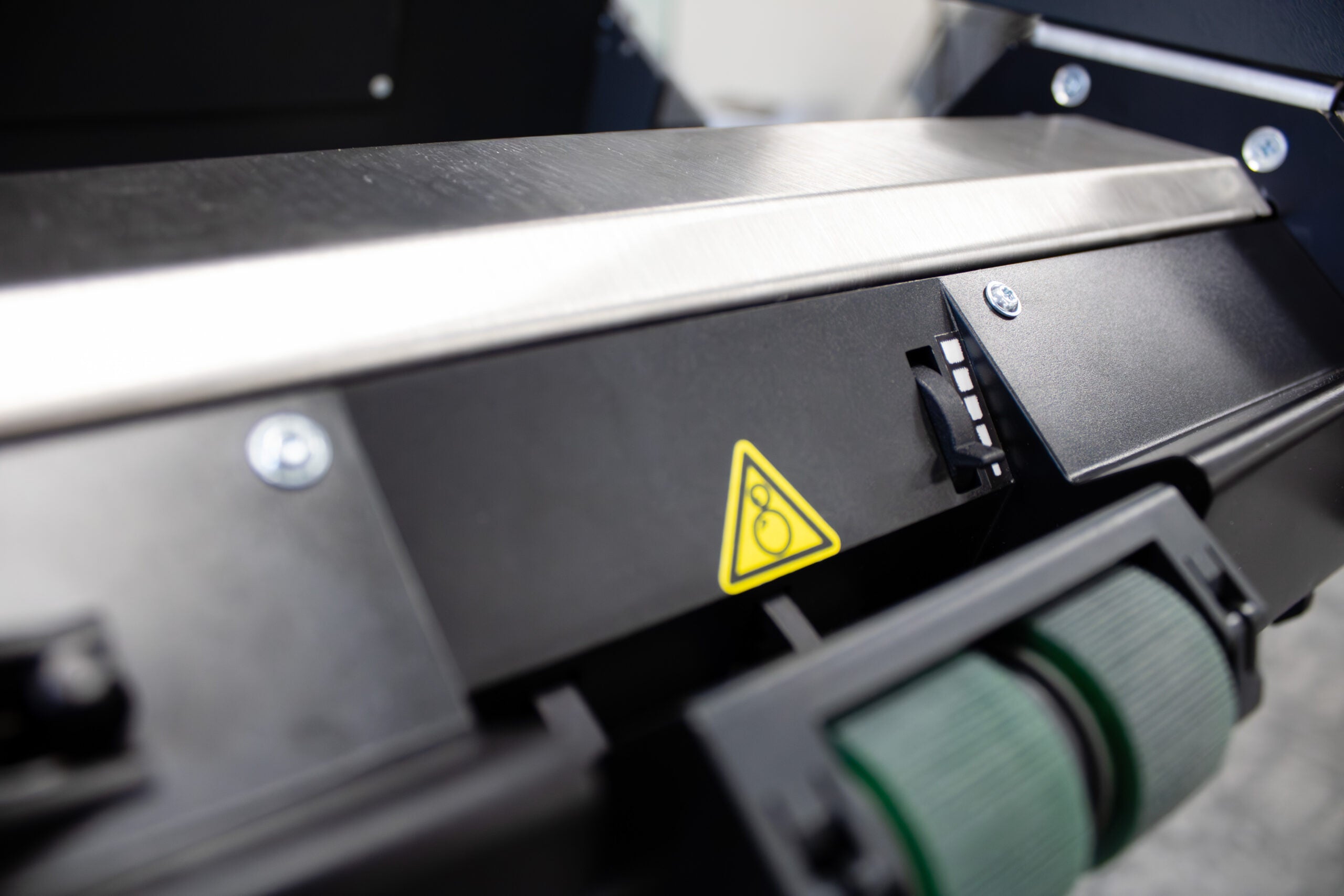

No-Scratch Gorilla Glass™

Hardened, scratch-resistant scan glass protects against abrasion caused by staples, paper clips, and debris that degrade image quality over time. Combined with high-quality CCD sensors, the no-scratch glass delivers consistent, edge-to-edge image clarity and lowers long-term maintenance costs.

Rear Exit Tray

A built-in rear exit tray enables straight-through document handling for fragile, thick, or long originals. Documents bypass tight turns in the paper path, reducing stress on materials while allowing active sorting or exception handling at full scan speed.

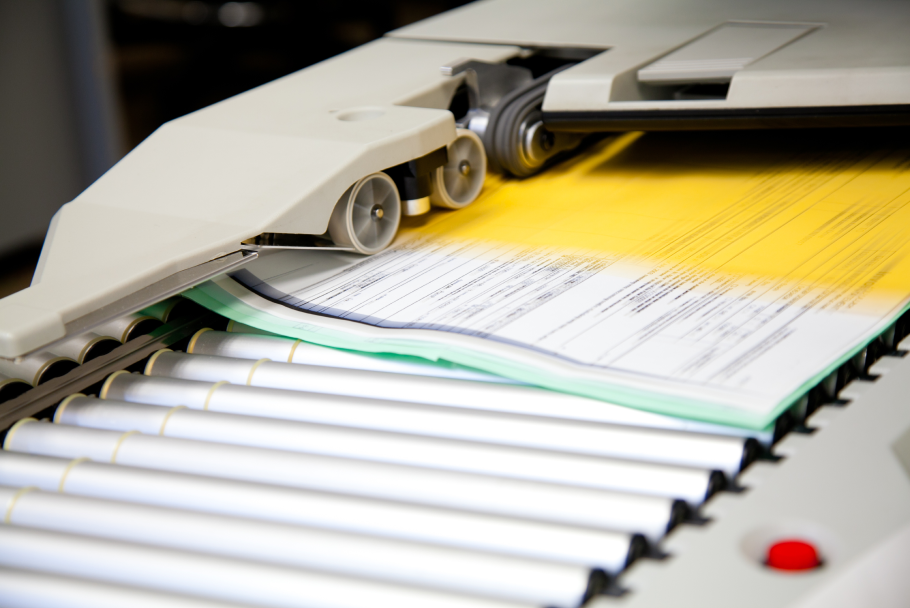

4-Tray Sorter (optional on 6000 series only)

The front-mounted 4-tray sorter adds automated active sorting based on system events without slowing throughput. Pages can be routed to different trays based on barcodes, patchcodes, document length, or scanner events—ideal for exception handling and mixed batches.

Velo Scan Capture Software

Included with every Velo scanner, Velo Scan capture provides reliable basic document capture with image based output.

Velo Scan+ Capture Software (optional)

Velo Scan+ unlocks advanced in-capture OCR, indexing, validation, workflow control, and secure export capabilities. By validating and structuring data at the scanner, Scan+ reduces downstream rework, accelerates integrations, and supports audit-ready, archive-grade output formats.

Find Out How Velo Can Improve Your Operations

“*” indicates required fields

Desktop Production Scanning That Keeps Work Moving

Velo 3120 and Velo 6000 Series scanners are built to eliminate bottlenecks in high-volume capture environments. By combining continuous-duty hardware, multi-sensor feed protection, and high-quality image output with archival capability, Velo delivers faster throughput, lower risk, and predictable results—day after day.

Durable

Unlimited Duty Cycle for Daily Production

Scan at full rated speed for hours or entire shifts without stopping. Unlimited duty cycles and high-quality components ensure high-volume jobs finish on time. Even under tight SLAs.

Protective

Gentle, Intelligent Document Handling

Safely process fragile, and aging documents through the feeder instead of on flatbed scanners. Adjustable input pressure, slowdown modes, and gentle belt transport reduce document damage while maintaining throughput.

Clear

Archive-Grade Image Quality

Produce consistently clean, sharp images that support OCR, IDP, and long-term preservation. Velo scanners meet FADGI and ISO 19264-1 standards—for archive-grade workflows.

Document Protection

Built-In Feed Protection & Detection

Avoid costly errors before they happen. Ultrasonic, metal, and staple detection identify double-feeds and hazards early, minimizing document loss, rework, and operator intervention.

Flexible

Straight-Through Paper Path

Handle long, thick, or delicate documents with confidence. Rear exit straight-path transport reduces stress on originals and allows exception handling without stopping production.

Active Sorting

Scalable Sorting & Workflow Control

Automate separation and exception handling at full speed. Event-based active sorting via the rear exit tray or optional 4-tray sorter (6000 Series only) keeps batches organized and moving.

Intuitive

Operator-First Design

Automate separation and exception handling at full speed. Event-based active sorting via the rear exit tray or optional 4-tray sorter (6000 Series only) keeps batches organized and moving.

Low Maintenance

Long-Life Consumables

Long-life components, no-scratch optics, and minimal consumables protect your investment and reduce service costs over the scanner’s lifecycle.

Integrated

Open Integration & Capture Flexibility

Deploy Velo into existing environments without disruption. TWAIN/ISIS compatibility and optional Velo Scan+ software simplify integration, validation, and secure delivery to virtually any ECM, IDP, or archival systems.

How are Velo scanners different from typical “high-speed” document scanners?

Unlike conventional high-speed scanners that prioritize speed alone, Velo 3120 and Velo 6000 Series scanners are engineered as true production systems. They combine continuous-duty hardware, gentle belt transport, multi-layer feed protection, active sorting and onboard image processing to deliver sustained throughput without sacrificing document care or image quality. The result is fewer rescans, decreased risk to originals, and predictable output that meets archival and compliance requirements—shift after shift.

FADGI Archive-Ready Image Quality (FADGI & ISO 19264-1)

Velo 3120 and Velo 6000 Series scanners are built to support archive-grade imaging when accuracy and compliance matter. Optional factory calibration aligns the scanner to FADGI and ISO 19264-1 standards, delivering consistent color, tone, and sharpness you can trust across large projects. That consistency helps organizations create defensible, repeatable images that stand up to audits, legal review, and long-term preservation requirements. When paired with Velo Scan+, outputs can be structured and validated for confident delivery into archival and records systems.

Discover How Velo Has Impacted Other Operations

The Importance of Data Security in Automated Document Management for Banks

Palm Beach County Tax Office

Automating Donation Processing for Nonprofits

Same-Day Delivery: Making It a Reality With Automated Sorting Systems

RMMI Streamlines Scanning Efficiency with OPEX® Falcon®+ One-Touch Scanners

Optimizing Your Warehouse Layout for Automation

Reducing Errors and Improving Accuracy With Automated Sorting in Logistics

Automating Invoice Processing for Energy Companies

Streamlining Operations: The Impact of Automation on Financial Institutions

Boosting E-Commerce Efficiency: The Role of Warehouse Automation

Next Level Automation

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.