Fast and Secure Remittance Processing

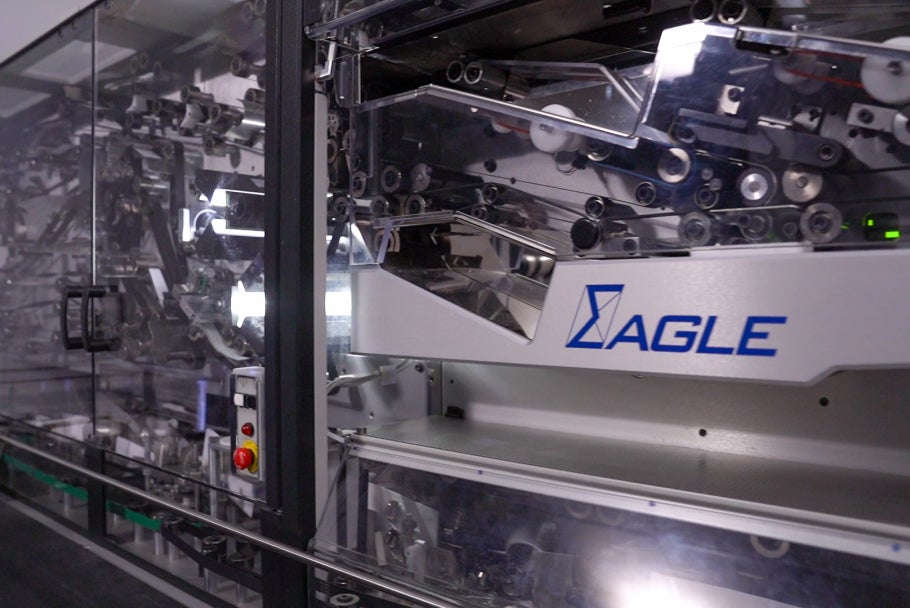

There’s no question that fast and secure check processing for high-volume conforming payment is non-negotiable. That’s why OPEX® designed the industry-leading Eagle™ remittance processing system. Ideal for businesses that handle thousands of remittance checks per day, Eagle removes the need for manual processing to help you receive payments sooner.

Meet Eagle

The Quickest Deposit-Ready System on the Market

Take your remittance processing to the next level with the quickest deposit-ready system on the market, the OPEX Eagle. Engineered to handle the process from beginning to end, the Eagle rapidly opens envelopes, extracts images, and sorts checks and payment coupons. By processing up to four transactions per second and up to 16,000 envelopes per hour, Eagle allows you to deposit payments quicker than ever. This fully automated, high-tech machine has been specifically designed to be operated by one operator.

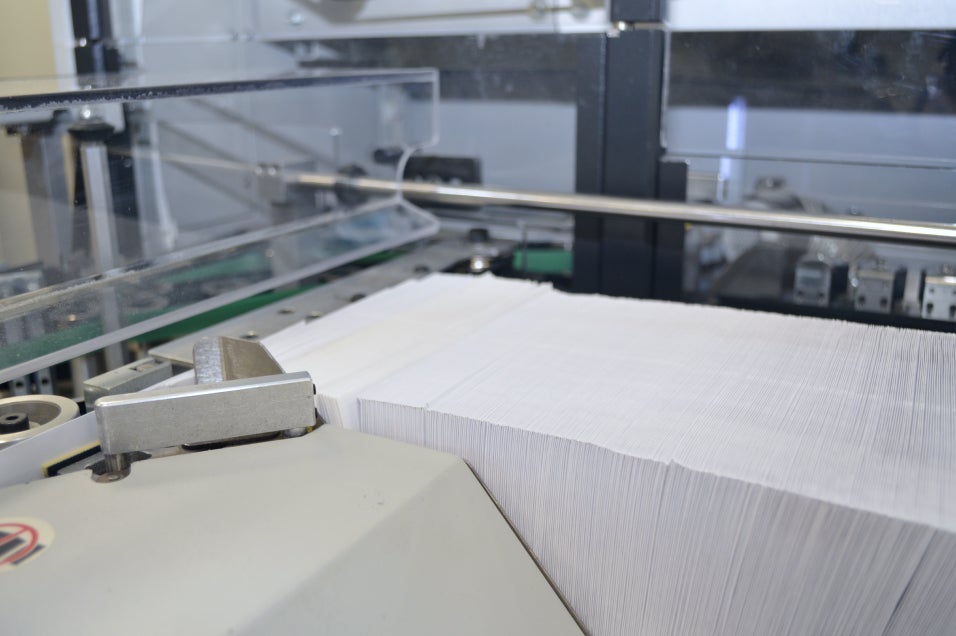

Automatic Feeder

Eagle’s automatic feeder transports unopened envelopes into the system and sorts out envelopes that are too thick or contain metal. Load remittance mail into the feeder, remove noticeably damaged envelopes and go.

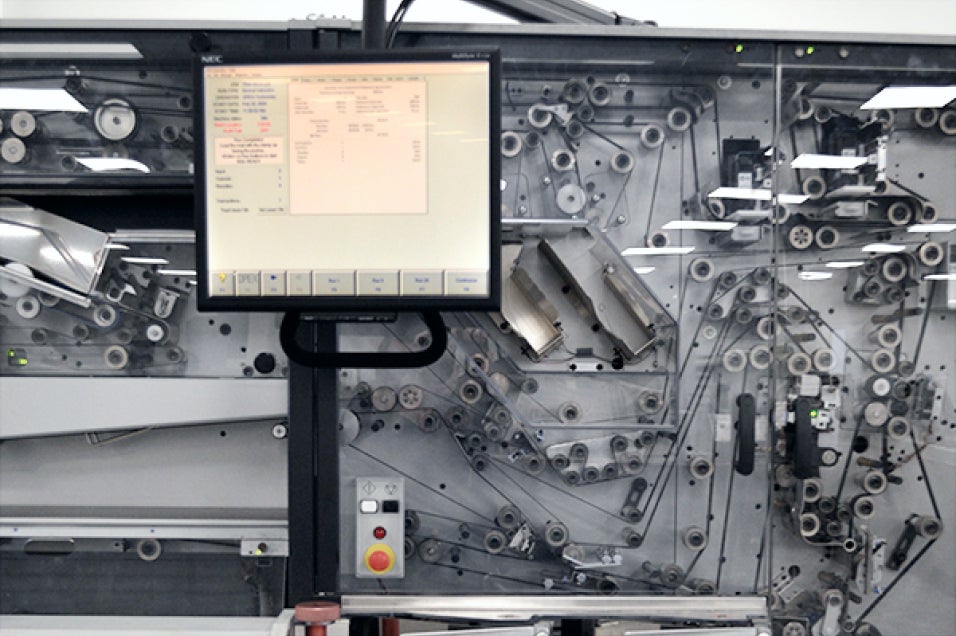

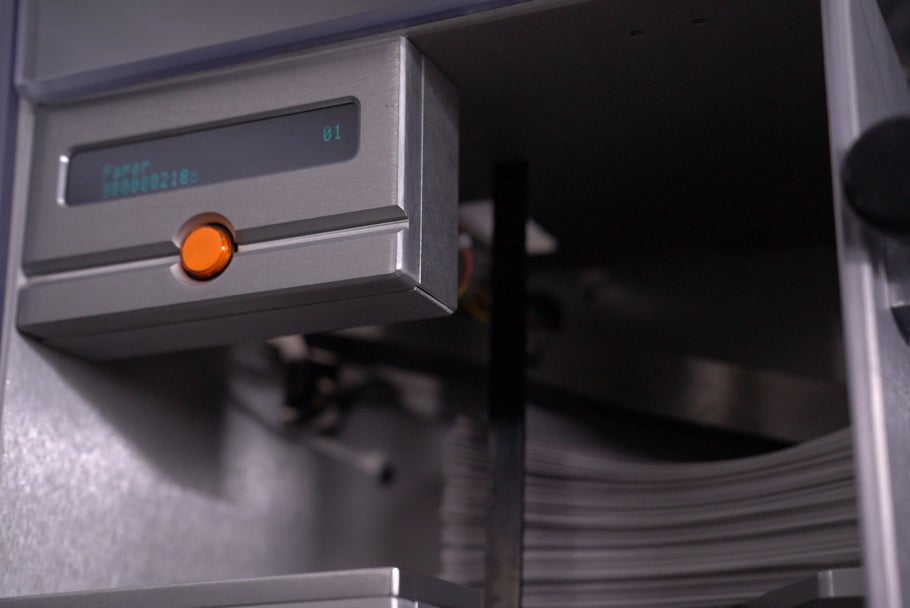

User-Interface

The Eagle is equipped with a simple user interface. Multiple user accounts are available to control the system, view performance statistics, access reports, and select specific jobs configured to your business rules.

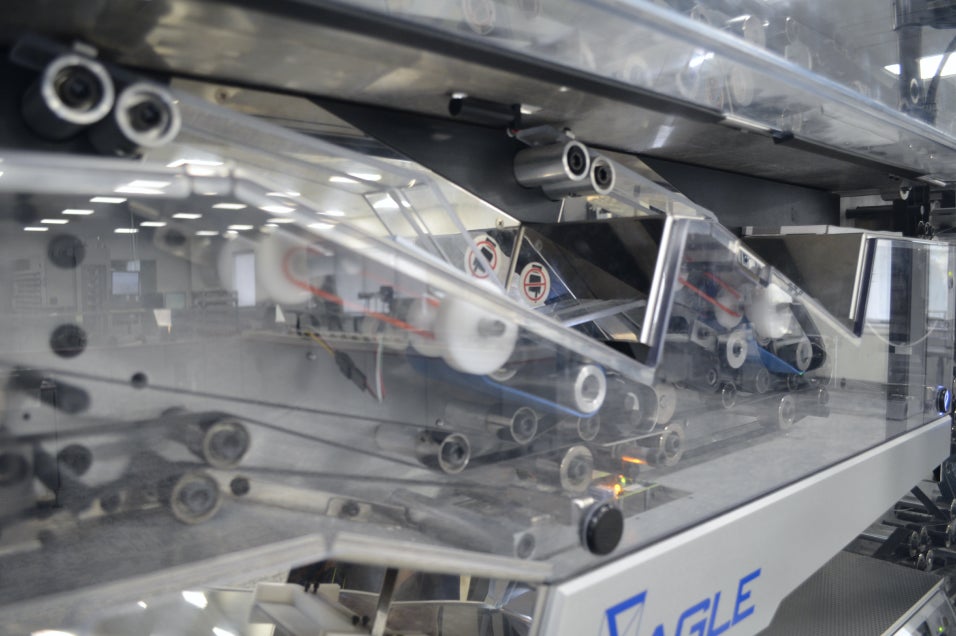

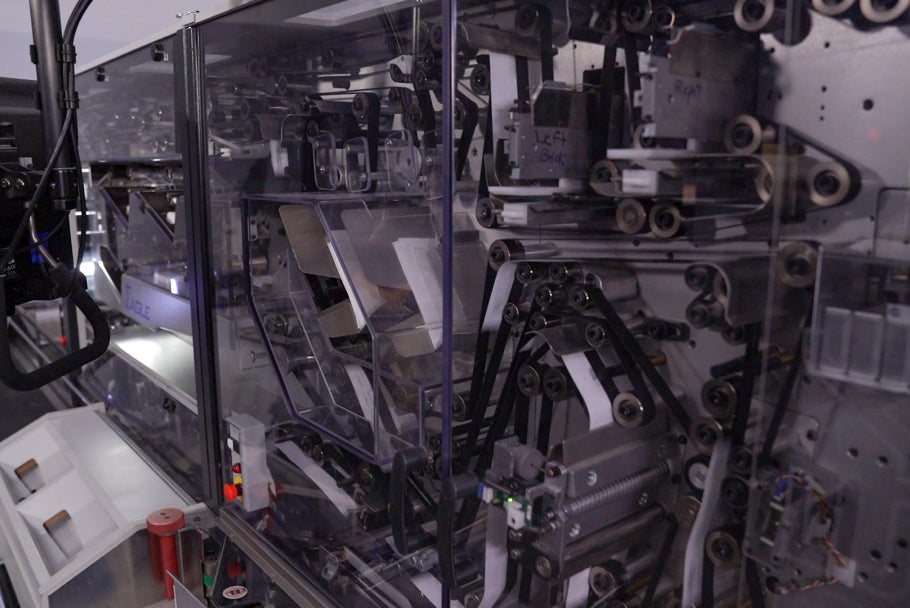

Enclosed Paper Path

The Eagle’s paper path ensures the security of the work that the Eagle processes. From the time an envelope enters the system until the check and document are stacked in the output bins, the paper path is enclosed to ensure that paper is not lost or misplaced.

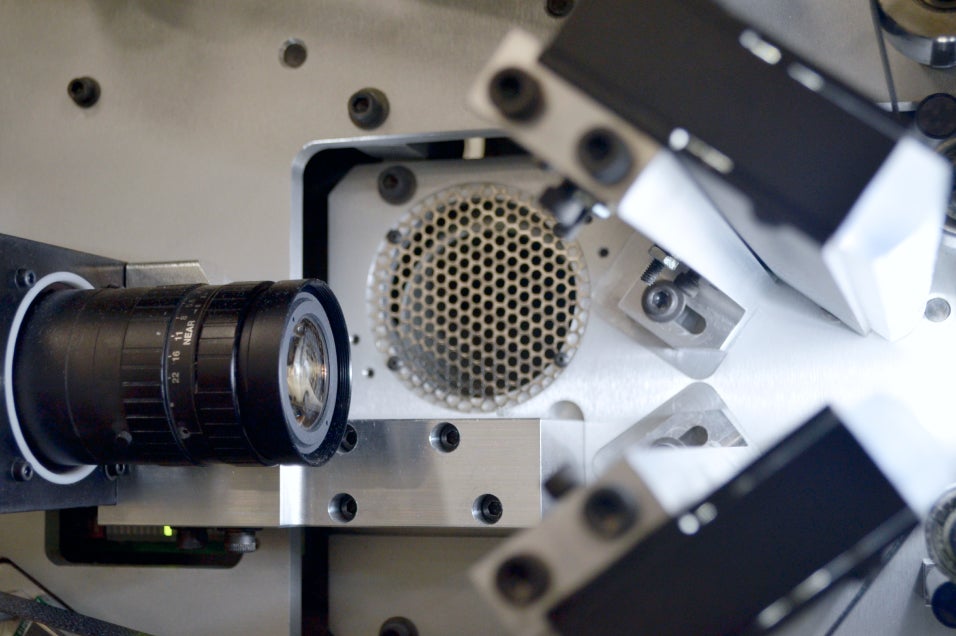

Image Export Module (IEM)

The IEM functionality captures front and back images of the check and payment coupon as they travel through the enclosed paper path. Eagle provides the necessary time for real-time decision-making, allowing for sorting and backend processing like Character Amount Recognition (CAR), Legal Amount Recognition (LAR), and Check 21. These processing decisions are made by your remittance provider and passed to the Eagle for proper decisioning and pocketing

Buffer Feeder

This secondary feeder stages pre-qualified “clean” payments before the extraction module. If the system sees a gap in the track, this feeder inserts an envelope into that gap to increase the overall system throughput.

Extractor Module

The extractor module qualifies each envelope prior to extraction of the content. All envelopes determined to include a clean payment, defined as a single unfolded check and a payment coupon, advance into the automated extractor module. The empty envelope is verified to confirm a successful extraction and then discarded into a large trash container. An optional audit trail can be applied after the pieces are removed from the envelope.

Output Stacker Module

Eagle’s e-Package comes standard with 16 output pockets (two (2) stacker modules). Up to two (2) additional stacker modules can be added if needed. A visual display at each pocket indicates what work has been deposited into that particular location. This display is adjustable within each programmed job.

Eagle |

|

|---|---|

| Length | 586.74 cm with two stackers; Length of stackers: 91.4 cm. each (4 total available) |

| Width | 187.96 cm |

| Height | 190.5 cm max (on shipping dolly) Operator/Service clearance of 91.44 cm around perimeter of machine recommended |

| Transport Speed | 406.4 cm/sec, content section |

| Input Rate | Up to 16,000/hr (19.5 cm) |

| Output Options | Contents in same or separate stacks, Document or check first in combined stack Document or check facing front or back in stack (16, 24, or 32 pockets.) |

| Envelope Specifications | |

| Length | 14.605 to 23.495 cm |

| Height | 6.985 to 10.795 cm |

| Paper Weight | 0.00816466 to 0.0108862 Metric Ton |

| Envelope fit tolerance | 3.81 cm minimum clearance required all around |

| Sorting Functions | Thickness - too thick or thin @ 0.0127 mm resolution Metal - most metal objects down to staple size Length - too long or short |

| Electrical Requirements | 208-230 VAC, single phase 50/60 Hz, 3-wire system 50 amps Fully configured machine: 7072 watts, 24152 BTU/hr. @ 34 amps |

| Environmental Specifications | Temperature - 18° to 30° C Humidity - 40% to 95% RH Sound level (average) - 84.5 db |

Eagle |

|

|---|---|

| Length | 19 ft 3 in with two stackers; length of stackers: 36 in each (4 total available) |

| Width | 74 in |

| Height | 75 in max (on shipping dolly) Operator/Service clearance of 36 in around perimeter of machine recommended |

| Transport Speed | 160 in/sec. content section |

| Input Rate | Up to 16,000/hr. (7.5" mail) |

| Output Options | Contents in same or separate stacks, Document or check first in combined stack, Document or check facing front or back in stack (16, 24, or 32 pockets.) |

| Envelope Specifications | |

| Length | 5.75-9.25 in |

| Height | 2.75-4.25 in |

| Paper Weight | 18-24 lbs. |

| Envelope fit tolerance | 1/8 in minimum clearance required all around |

| Sorting Functions | Thickness - too thick or thin @ .0005 in resolution Metal - most metal objects down to staple size Length - too long or short |

| Electrical Requirements | 208-230 VAC, single phase 50/60 Hz, 3-wire system 50 amps Fully configured machine: 7072 watts, 24152 BTU/hr. @ 34 amps |

| Environmental Specifications | Temperature - 60° to 85° F Humidity - 40% to 95% RHSound level (average) - 84.5 db |

Find Out How Eagle Can Improve Your Operations

“*” indicates required fields

Process Payments Faster with More Output

Turn your lockbox remittance operations into a fast, streamlined process with the Eagle remittance processor. Eagle’s robust envelope opening and contents extraction, imaging, and sorting abilities will help increase your efficiency and output, improving the experience by allowing you to process more payments with less labor.

Quick

Receive Payment Faster

- Process payments faster than ever: the Eagle processes up to four transactions per second, opening up to 16,000 envelopes per hour.

- Little to no prep or pre-sorting significantly speeds up your process.

- Employees can focus on more value-adding tasks and higher priorities.

Secure

Enhance Security

- Minimal information handling limits the number of individuals who have access to critical customer information, helping to prevent unauthorized use of data.

- User access controls and an optional audit trail printer allow for traceability.

- Eagle handles envelopes and contents safely, reducing the risk of losing or damaging documents.

Streamlined

Improve the Customer Experience

- Accelerated processing and minimal prep needs to reduce turnaround time.

- Unmatched payment processing speed and accuracy.

- Eagle will help you to meet/exceed your SLAs even during peak volume days.

Reliable

Keep Operations Moving

- OPEX provides service support and preventive maintenance to keep your system up and running and keep downtime at a minimum.

- Eagle’s industrial quality easily handles high volumes without negatively impacting the system.

- The system is installed quickly, and staff can be trained easily, helping to minimize any interruptions.

Flexible

Efficiently Process Remittance

- Eagle automatically processes different envelope jobs by a simple operator selection of the next job to run, with virtually no pre-sorting required to streamline your workflow.

- Integration already exists with all major remittance software providers.

- Eagle can be operated as a fully integrated system for opening, extracting, and imaging. It can also be used for high-speed image transport and imaging work that has already been opened on the production floor.

for multiple reasons, but the most important reason was scalability.”

Chuck Cornwell

GM and Senior Operations Manager, Newegg

Discover How Eagle Has Impacted Other Operations

Case Study

How Ingram Micro Increased Throughput in a Small Footprint

15 min read

White Paper

Scalable Storage and Retrieval to Match Warehouse Progressive Demands

15 min read

Insight

Optimizing Inventory Storage with a Dense ASRS

15 min read

Last Item

Last item text for final slider item on this page

15 min read

NEXT LEVEL AUTOMATION

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.