メール開封の合理化と効率の向上

自動封筒開封を次のレベルに引き上げるOPEX® OMATION®メール開封システムは、生産性と効率性の向上により、メールルームを強力にサポートします。当社のさまざまなOMATIONシステムは、印刷、シーケンス、プリセットジョブ、追加の仕分け位置などの高度な機能によって、絶えず変化するワークフローのさまざまなニーズを満たすように設計されています。

Introducing OMATION® Model 606™ Envelopener®

Introducing OMATION® Model 606™ Envelopener®

The OMATION® Model 606™ Envelopener® is a high-volume mail processing system that can handle up to 40,000 envelopes per hour. It features cutting-edge technology, an intuitive LCD touchscreen, and an engineered feeder to prevent misfeeds and interruptions. This system provides performance tracking to optimize operations, making mail processing faster, safer, and more efficient.

Meet OMATION® Series 410™ Envelopener®

Series 410 印刷・シーケンス機能付き少量メール開封機のご紹介

Meet OMATION® Series 210® Envelopener™

少量メール開封機

自動調整式オートフィーダー

OMATION systems have a self-adjusting feeder to accommodate mixed envelope types, sizes, and thicknesses. Easily open standard, thin, thick, airmail, and overnight envelopes all on one platform at a rate of up to 24,000 envelopes per hour on the Series 210 and 410 systems and 40,000 envelopes per hour on the Model 606.

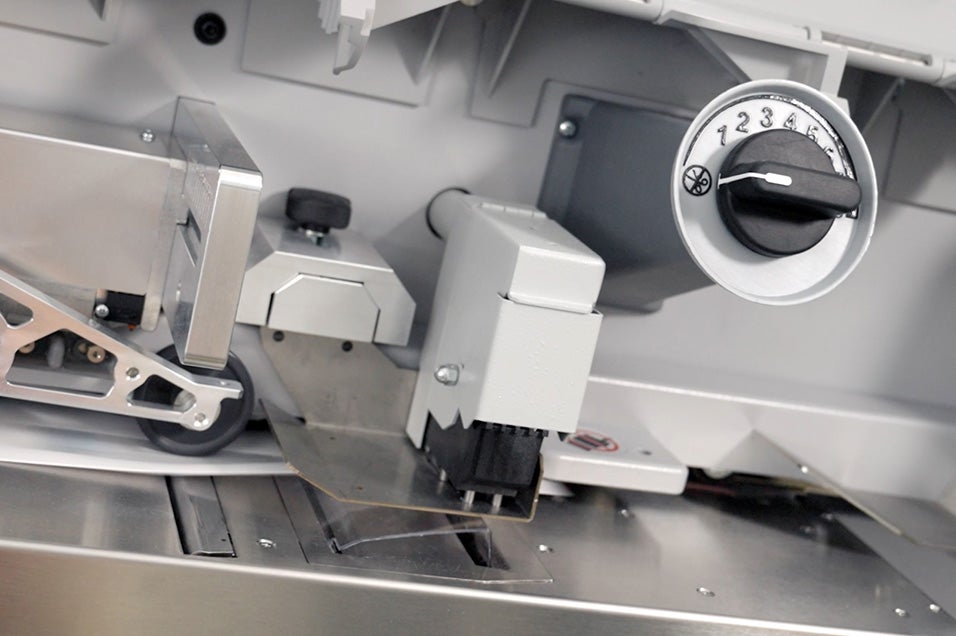

ミリングカッター

All OPEX mail opening systems include specialized milling cutting technology, which chips away as small as 0.01” (0.25 mm) from the edge to create a clean, soft, feathered opening. This method is much safer than using blades. Not only does it significantly reduce paper cuts, but there’s less risk in cutting the envelope contents.

切込み深さの調整が可能

OMATION Series 210 and 410 mail openers have a cut-depth adjustment knob with three optimal cut-depth settings for fine, medium, and heavy-weight envelopes. The OMATION Model 606 system has eight adjustable cut-depths for different envelope weights ranging from 0.01” (0.25 mm) up to 0.125” (3.175 mm). All OMATION systems have a no-cut setting available for envelope counting and sorting.

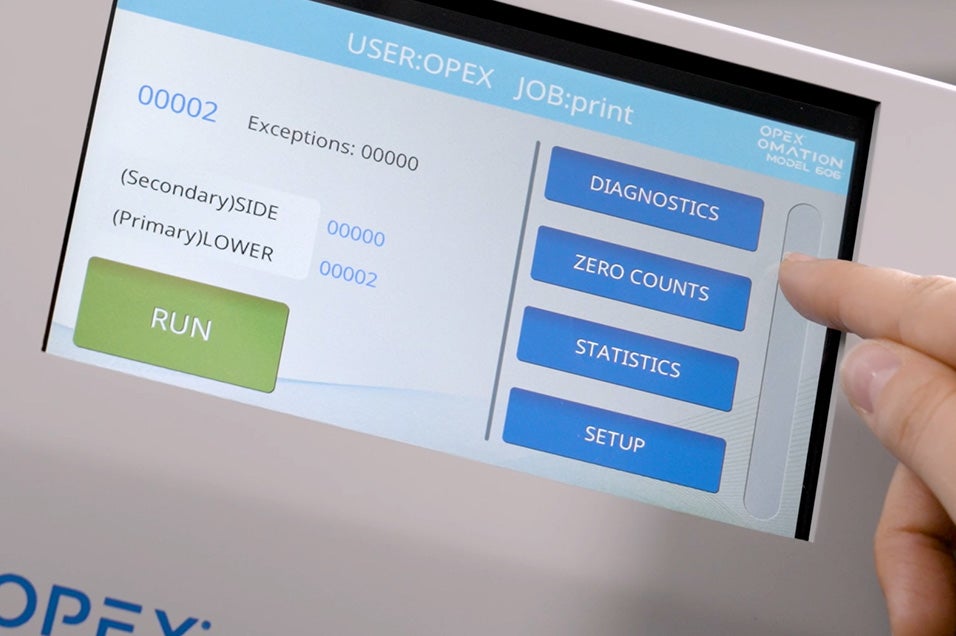

ユーザーフレンドリーなインターフェース

Easily control the system and view envelope counts with a display and keypad controls on all OMATION systems. For more advanced workflows, the Series 410 opener has a 5.5” (13.94 mm) display for users to choose from eight preset jobs and view envelope counts. The new and improved user-friendly operator-controlled LCD interface on the Model 606 supports numerous job settings, multiple operators, and several languages.

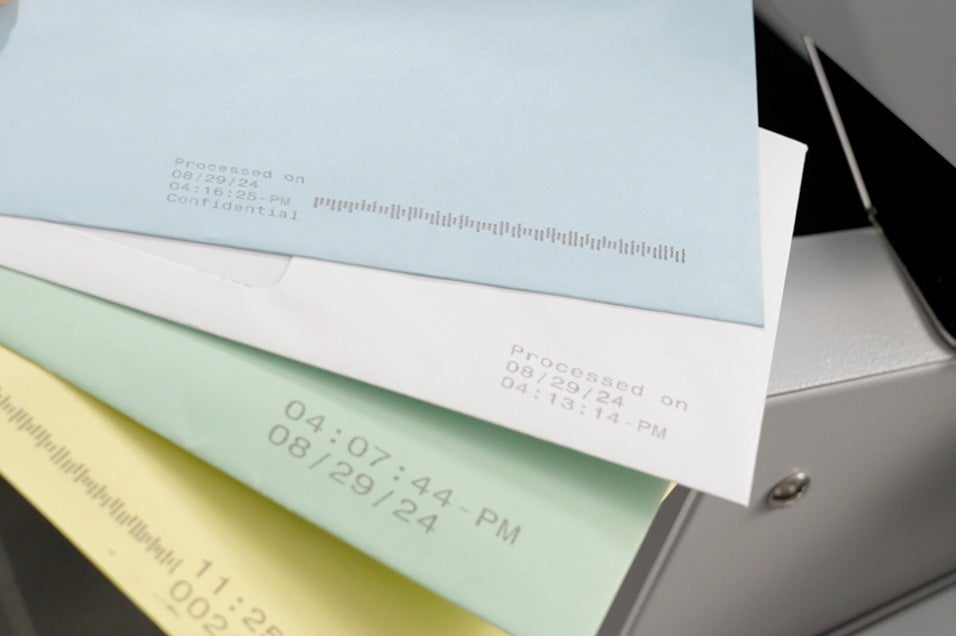

Built-in Printer (Optional)

Print the date, time stamp, and sequence number on each envelope as it passes through the Series 410 system and Model 606 mail openers with a built-in inkjet printer to improve traceability for each mail piece.

切り屑ビン/インターロックシステム

Series 210および410開封機は、最大3,500通の封筒を空にする前に開くことができる切り屑ビンを備えています。インターロックシステムは、切り屑ビンが取り外されたときにマシンが動作するのを防ぎます。

OPTIONAL Sorter

An optional 90° sorting conveyor or sorting bin is available on the Model 606 envelope opener. Making it a perfect fit for applications requiring verification of contents before or after extraction. Envelopes can be sorted into two locations based on programmable criteria such as thickness, length, and height.

|  |

||

|---|---|---|---|

| Length | 1219.2 mm | 1023.6 mm | 1023.6 mm |

| Depth | 514.35 mm | 419.1 mm or 457.2 mm with power cord | 419.1 mm or 457.2 mm with power cord |

| Height | 1492.25 mm | 363.2 mm | 363.2 mm |

| Weight | 106.6 kg (stand & waste bin included) | 24.94 kg | 23.6 kg |

| Speed | Up to 40,000 envelopes per hour | Up to 400 envelopes per minute (152.4 mm envelope) | Up to 400 envelopes per minute (152.4 mm envelope) |

| Envelope Sizes & Types | Lengths up to 342.9 mm. including overnight packs sort capabilities on the first 279.4 mm of envelope | All sizes and types (including overnight envelopes) | All sizes and types (including overnight envelopes) |

| Thickness | up to 12.7 mm envelope thickness | Up to 4.7752 mm envelope thickness | Up to 4.7752 mm envelope thickness |

| Depth of Cut | From 0.3 mm from envelope edge up to 3.2 mm in depth | From 0.254 mm to 1.778 mm | From 0.254 mm to 1.778 mm |

| Electrical Requirements | 115 VAC, 60HZ, 8.5A 3338 BTU/h (115 VAC) 230 VAC, 50HZ, 5.5A 4317 BTU/h (230 VAC) | 110-120 VAC, 60HZ, 5A 1964 BTU/h (max @ 115v/5A) | 110-120 VAC, 60HZ, 5A 1964 BTU/h (max @ 115v/5A) |

| Decibel Rating | Does not exceed safety standard of 80db | Does not exceed safety standard of 80db | |

| Batching | Batching allows operators to group items into pre-selected lot sizes, ensuring maximum productivity by focusing on "clean" batches rather than handling exceptions at the same time. | ||

| 90° Powered Conveyor or Sort Bin | An optional 90° sorting conveyor or sort bin makes the Model 606 envelope opener a perfect fit for applications that require verification of contents either before or after extraction. | ||

| Reports Printer | Produces a variety of statistical reports for monitoring machine performance | ||

| High-Speed Inkjet Printer | Prints a variety of custom strings, including date & time, sequential numbering, ID Tag, and IMB Barcode | Prints date and time audit trails and unique number sequencing for traceable mail |

|  |

||

|---|---|---|---|

| Length | 48 in | 40.3 in | 40.3 in |

| Depth | 21 in | 16.5 in or 18 in with power cord | 16.5 in or 18 in with power cord |

| Height | 58 in | 14.3 in | 14.3 in |

| Weight | 235lbs (stand & waste bin included) | 55 lbs | 52 lbs |

| Speed | Up to 40,000 envelopes per hour | Up to 400 envelopes per minute (6 in envelope) | Up to 400 envelopes per minute (6 in envelope) |

| Envelope Sizes & Types | Lengths up to 13.5 in. including overnight packs sort capabilities on the first 11 in of envelope | All sizes and types (including overnight envelopes) | All sizes and types (including overnight envelopes) |

| Thickness | up to 0.5 in envelope thickness | Up to 0.188 in envelope thickness | Up to 0.188 in envelope thickness |

| Depth of Cut | From 0 - 0.01 in from envelope edge up to 0.125 in in depth | From 0.01 in to 0.07 in | From 0.01 in to 0.07 in |

| Electrical Requirements | 115 VAC, 60HZ, 8.5A 3338 BTU/h (115 VAC) 230 VAC, 50HZ, 5.5A 4317 BTU/h (230 VAC) | 110-120 VAC, 60HZ, 5A 1964 BTU/h (max @ 115v/5A) | 110-120 VAC, 60HZ, 5A 1964 BTU/h (max @ 115v/5A) |

| Decibel Rating | Does not exceed safety standard of 80db | Does not exceed safety standard of 80db | |

| Batching | Batching allows operators to group items into pre-selected lot sizes, ensuring maximum productivity by focusing on "clean" batches rather than handling exceptions at the same time. | ||

| 90° Powered Conveyor or Sort Bin | An optional 90° sorting conveyor or sort bin makes the Model 606 envelope opener a perfect fit for applications that require verification of contents either before or after extraction. | ||

| Reports Printer | Produces a variety of statistical reports for monitoring machine performance | ||

| High-Speed Inkjet Printer | Prints a variety of custom strings, including date & time, sequential numbering, ID Tag, and IMB Barcode | Prints date and time audit trails and unique number sequencing for traceable mail |

オメーションが御社のオペレーションをどのように改善できるか

“*” indicates required fields

より迅速で効果的なメール開封で生産性を向上

効率性

ワークフローの効率性を向上

- 高速で手間のかからないメール開封により、ワークフロー全体を高速化します。

- 特殊なミリングカッティングテクノロジーにより、柔らかい羽根状の端部が形成され、封筒から内容物を簡単に取り出せ、封筒の内容物を損傷するリスクを最小限に抑えます。

- Additional sorting features available on OMATION Model 606 systems help reduce the need for pre-sorting.

信頼性

ダウンタイムを最小化

- OPEXが提供する迅速な製造、設置、トレーニング、サービスにより、迅速に稼働できます。

- OPEXの社内技術サポートとサービスにより、あらゆる問題を解決し、予防保守を実行してダウンタイムを最小限に抑えることができます。

- 自動化されたメールの迅速な開封でワークフローを動かし続け、手作業による開封のボトルネックを解消します。

セキュリティ

セキュアなメール処理

- 特定のOMATIONシステムでは、追加の印刷およびシーケンシング機能を利用して、メールのトレーサビリティとアカウンタビリティを向上させることができます。

- ミリングカッティングテクノロジーにより、封筒内容物の損傷を防ぎます。

オメーションが他事業に与えた影響を探る

倉庫に自動化改革が必要な5つのサイン

倉庫管理の未来は自動仕分けにある

アイウェア仕分けのための実証済みのソリューション

倉庫における将来的な人間とロボットの協働:安全に生産性を高める

NEXT LEVEL AUTOMATION

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.