Order Retrieval and Delivery

Automated Pack-out and Takeaway System

Seamless Order Retrieval, Transfer, and Fulfillment

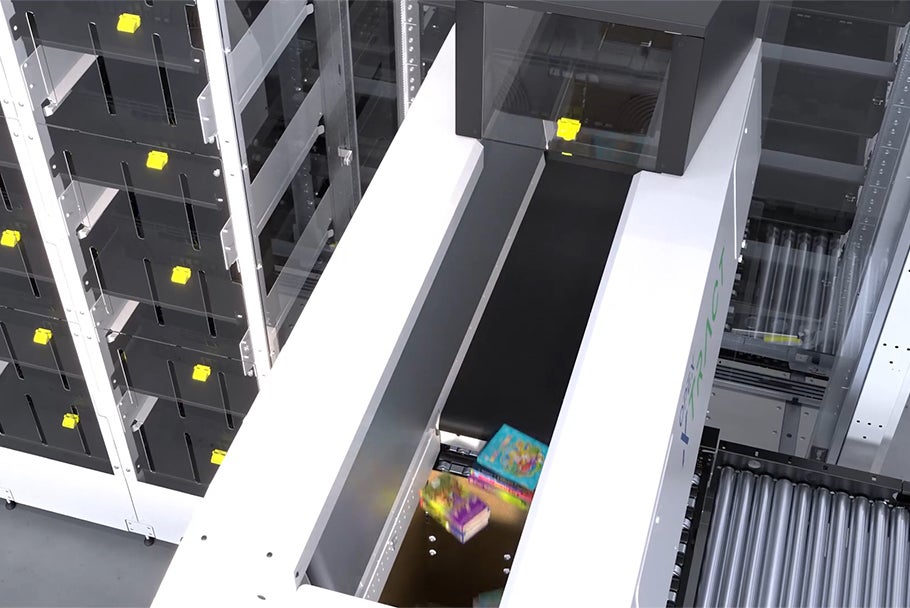

OPEX® Sure Sort® X with Xtract™ was specifically engineered to combat labor shortage challenges by automating three fundamental aspects of order fulfillment: the sorting retrieval and removal of completed orders.

Meet Sure Sort X with Xtract

Automated Order Takeaway

The new OPEX Sure Sort X with Xtract is the only fully adaptable, turnkey solution on the market developed to address labor shortage challenges by automating key aspects of order fulfillment―high-speed sortation through consolidating batch- or wave-picked inventory and the previously manual order takeaway process―with a return on investment often realized within just two years.

OPEX Xtract is an optional feature for Sure Sort X that automates the order takeaway process. The Xtract iBOT®s retrieve totes containing sorted orders and dispense them into the proper container, including shipping boxes, for downstream processing.

Xtract iBOTs

Xtract iBOTs efficiently retrieve Xtract Totes carrying up to 30 lbs (13.61 kg). They operate alongside Sure Sort X iBOTs, communicating wirelessly with the traffic controller and self-charging during movement. They can be easily added or removed for flexibility.

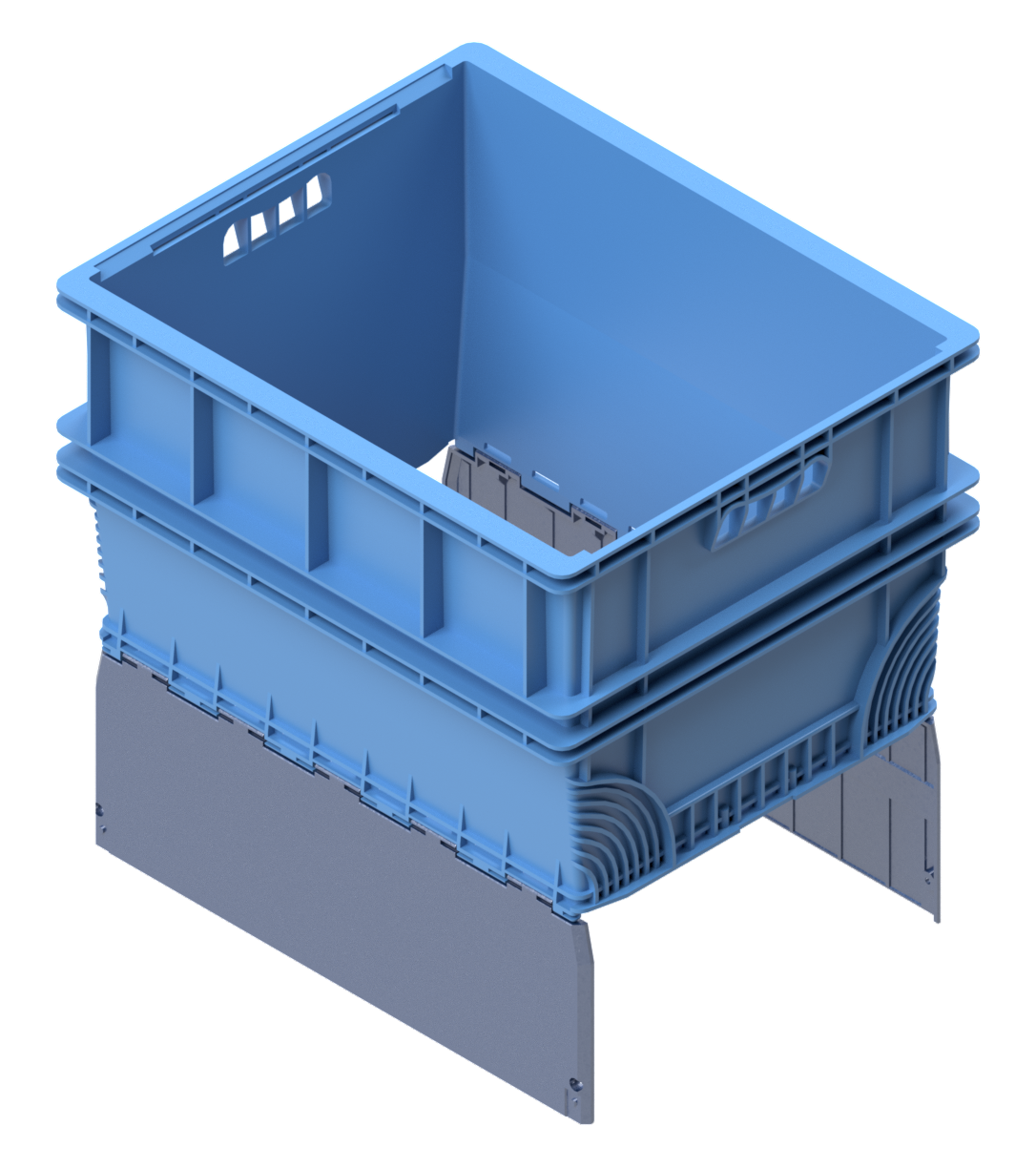

Xtract Tote

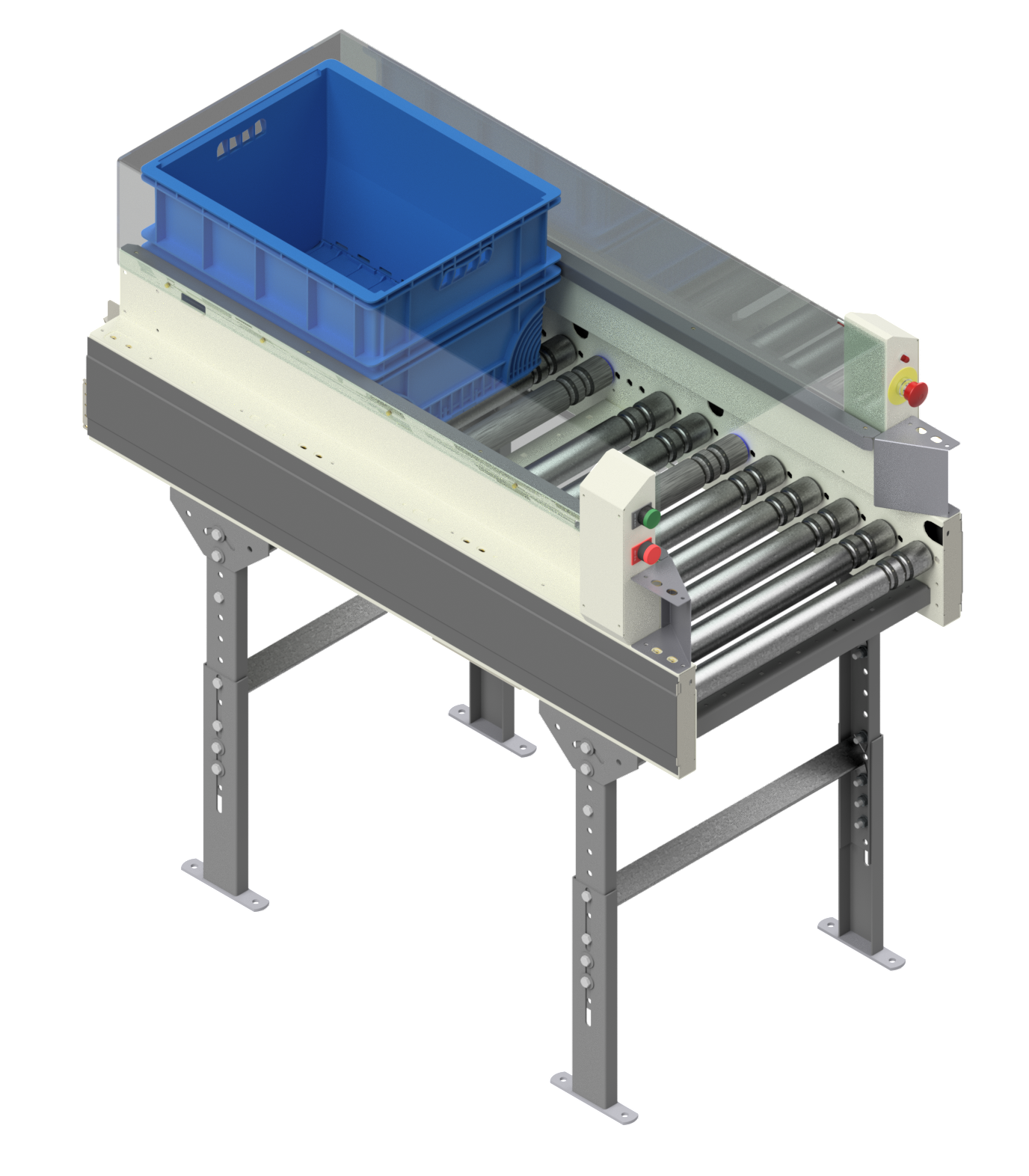

RVT (Roller, V-Chute, Transfer) Modules

Xtract Tote Input & Output (I/O) Modules

Sure Sort X with Xtract |

|

|---|---|

| Length | 5.03 m up to 25.51 m |

| Width | 4.46 m at the input conveyor, 5.96 m overall |

| Height | 3 m |

| Environment | Chilled (1.1 ℃ Non-Condensing) to Ambient (32.2 ℃ Max) |

| Sortable Item Length x Width Minimum | 3.2 cm x 3.2 cm or 13 cm2 |

| Sortable Item Length x Width Maximum | 43.2 cm x 31.8 cm |

| Sortable Item Height | 0.03 cm to 20.3 cm |

| Sortable Item Weight | 9 kg |

| Completed Order Weight | Up to 13.6 kg excluding weight of Xtract |

| Xtract iBOTs | Up to 20 combined OPEX Xtract and Sure Sort X Sortation iBOTs |

| Xtract Totes External | 48.3 cm x 40 cm [L x W], 30.5 cm or 16.5 cm [H] |

| Throughput | Up to 1800 units sorted & 200 orders extracted per hour |

| RVT Modules | Up to 5 per system installed on either or both sides of Sure Sort X |

| Final Order Container | Boxes, Totes, Bags |

| Tote IO Module | Xtract totes can leave system to transfer content or route to external pack station |

Sure Sort X with Xtract |

|

|---|---|

| Length | 16.5 ft up to 83.7 ft |

| Width | 14.6 ft at the input conveyor; 18.3 ft |

| Height | 9.8 ft |

| Environment | Chilled (34° F Non-Condensing) to Ambient (90° F Max) |

| Sortable Item Length x Width Minimum | 1.25 in x 1.25 in or 2 in2 |

| Sortable Item Length x Width Maximum | 17 in x 12.5 in |

| Sortable Item Height | 0.01 in to 8.0 in |

| Sortable Item Weight | Up to 20 lbs |

| Completed Order Weight | Up to 30 Ibs excluding weight of Xtract |

| Xtract iBOTs | Up to 20 combined OPEX Xtract and Sure Sort X Sortation iBOTs |

| Xtract Totes External | 19 in x 15.75 in [L x W], 12 in or 6.5 in [H] |

| Throughput | Up to 1800 units sorted & 200 orders extracted per hour |

| RVT Modules | Up to 5 per system installed on either or both sides of Sure Sort X |

| Final Order Container | Boxes, Totes, Bags |

| Tote IO Module | Xtract totes can leave system to transfer content or route to external pack station |

Find Out How Sure Sort X With Xtract Can Improve Your Operations

“*” indicates required fields

Adaptable, Efficient, and Scalable Solutions for Modern Fulfillment

Configurable

Tailored to Your Needs

- Sure Sort X with Xtract’s scalable design enables businesses to effortlessly expand their system, accommodating growth and peak seasons without major operational disruptions.

- The system supports easy accommodation of increased demand by allowing the addition of up to five iBOTs or RVT modules.

- This flexibility ensures businesses can maintain efficiency and adaptability as they scale.

Efficient

Rapid Order Processing and Improved Accuracy

- The system boasts a processing capacity of up to 1,800 units and 200 orders per hour, drastically reducing order processing times.

- By leveraging Sure Sort X with Xtract, businesses can achieve tight fulfillment deadlines and significantly improve customer satisfaction through automated order sequencing and fulfillment.

- The integration of technology minimizes human error, ensuring accurate and efficient order processing across various locations.

Streamlined

Enhanced Workflow Integration

- Integrating sortation, order retrieval, and takeaway into a single system streamlines operations, reducing the need for multiple vendors and simplifying workflows.

- The integrated system supports efficient item sequencing and flexible processing, enabling businesses to meet diverse order fulfillment demands effectively.

- By enhancing operational efficiency and minimizing bottlenecks, the unified approach leads to less downtime and operational challenges.

Cost-Effective

Optimized Resource Use

- Automating order sorting and unloading can significantly decrease labor costs by reducing dependence on manual labor while still ensuring high throughput.

- The system’s ability to handle large order volumes quickly and with minimal errors results in cost savings, enhanced productivity, and a reduced rate of returns from incorrect shipments.

“OPEX WAS A TRUE PARTNER.

THE PERFECT PICK WAS INSTALLED AND OPERATIONAL EXACTLY AS PROMISED.”

Richard Davidson

Project Manager

Discover How Sure Sort X Has Impacted Other Operations

OPEX and Iron Mountain UK Partnership

Cooksongold Enhances the Fulfillment Process For Its People, Adopting the Gold Standard in Automation

Record Partners Provides High-Volume Critical Record Digitisation with New Technology

Optimising Operations: Strategies for Efficiency and Cost Control in UK Logistics

Navigating the UK Logistics Workforce: Strategies for Resilience and Growth in an Automated Era

The Definitive Guide to Warehouse Automation in the UK

Investing in Sustainability: Addressing the Cost Barrier and Seeking Government Support

Building A Greener Supply Chain: The Role of Sustainability

Integrating ESG (Environmental, social and governance) into Business Strategy: Building a Sustainable Future

Developing Leaders: Why Succession Planning is Key to Long-Term Success in Logistics

NEXT LEVEL AUTOMATION

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.