Manufacturing Automation

Move More. Handle Less

ASRS and automated sortation keep parts on time, cut manual touches, and keep lines flowing, even in tight spaces and temperature controlled environments, so you hit takt with fewer stops and less overtime.

US-built, with local service and fast spare parts.

Throughput

Up to 600 dual cycles/hr

Specs

1.5s transfer

30″ x 20″ totes

Process

Simulation-first sign-off

Origin

U.S. manufactured

Why This Works

Buffers WIP and finished goods, releases material by priority, and feeds lines at the right time without adding travel. OPEX ASRS systems suit tight footprints and temperature-controlled areas.

Deterministic routing sends the right tote, tray, or carton to the best next step. Automated sortation balances stations, protects takt during changeovers and micro stoppages, and lifts accuracy.

Timed hand-offs between cells that prevent choke points. Integrates with existing conveyors and controls to keep operations at the cell.

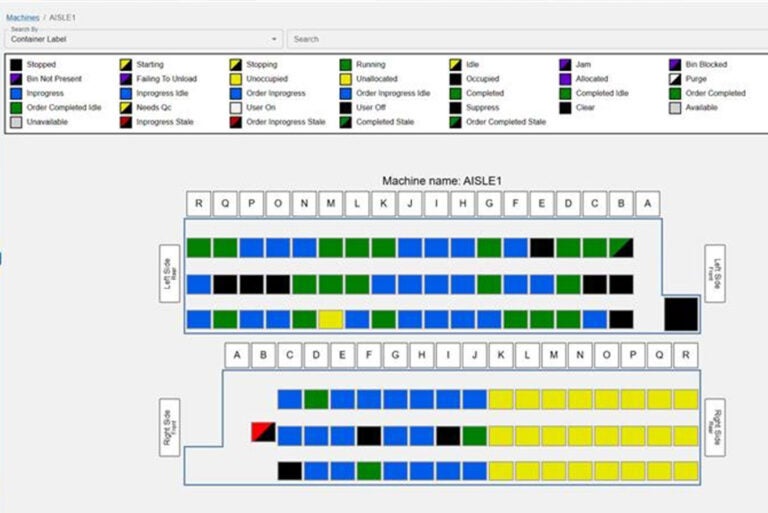

Workflow Software

An integration software suite to allow our systems to integrate into any OMS, ERP, or MPS, etc.

What Operations Leaders Get

- Throughput per labor hour up, without adding heads

- Walk and wait time down, operators stay at work cell

- Line side stockouts down, kitting accuracy up

- More production in the same footprint

- Stable, predictable flow you can schedule and staff against

Where it Fits

- Line side replenishment and supermarkets

- Kitting for assembly in automotive, aerospace, and electronics

- Post process buffering and pack out for CPG and food and beverage

- Spare parts and aftermarket fulfillment inside plant or DC

- Lot tracking, QA holds, and rework loops without choking flow

Our Process

Throughput Assessment

Share SKU mix, volumes, takt, shifts, and constraints. We model ASRS feed rates and sortation logic against your lines and identify choke points.

Design and Integration

Define tote sizes, inference points, coding, and control logic. Keep what works, insert ASRS and sortation where impact is highest, and add Tote IO only where it removes handling.

Pilot to Scale

Stand up one flow cell, validate KPIs, then expand across departments with minimal disruption.

What Smart Teams Ask

In a majority of cases, no. We design to your current environment and phase upgrades where ROI is clear. There may be a small number of cases where existing conveyance cannot accommodate.

Yes. The software layer exchanges only what is required for priorities, confirmations, and exceptions.

Every tote or load is tracked through the ASRS and sortation with scan or vision checkpoints for full genealogy.

Third-party conveyance responsibilities and warranties are defined up front. Roles and boundaries are clear so there are no surprises.

Performance is engineered, not assumed. We simulate aisle length, tote heights, device counts, and I/O locations. Acceptance criteria are agreed upon before installation.

OPEX proudly manufactures its automation solutions in the United States, leveraging in-house capabilities across machining, welding, painting, and proprietary assembly processes. With facilities in New Jersey and Texas, OPEX supports global demand while investing in local talent through training programs and advanced technologies.

Industry Use Cases

Automotive and Heavy Equipment

- Stabilize kitting to protect takt during model changeovers

- Feed mixed-model assembly with right time totes

Electronics and High Mix Assembly

- Short runs, many SKUs, tight takt, traceability required

- Reduce walk miles and balance stations with deterministic routing

Food, Beverage, and Cold Chain

- Automate tote movement inside cold rooms to reclaim capacity

- Reduce door open time and labor exposure in low temp zones

Talk to an Automation Expert

One minute form. An expert will reach out to understand your current environment and you’ll get a tailored estimate with modeled feed rates, labor impact, likely constraints, and expected gains.

What Happens Next

We run a quick model of feed rates, buffers, and likely choke points across ASRS, sortation, and transfers.

You receive a simple throughput estimate with assumptions and expected gains tied to your takt and SKU mix.

If the fit is strong, we propose a pilot plan with clear acceptance criteria.

Clear roles for conveyance and warranty boundaries are defined up front. No surprises.